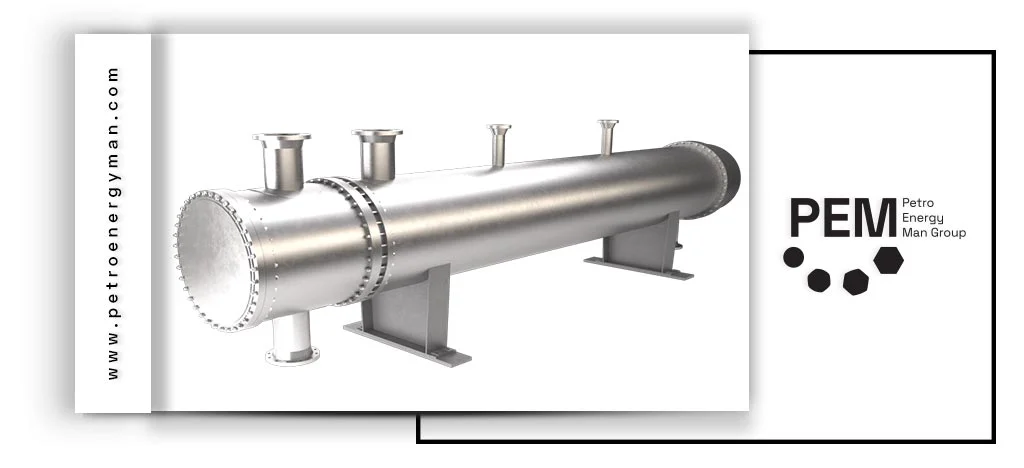

Heat exchangers manufacturers are essential in industries like oil, gas, petrochemical, and power. Among them, Petro Energy Man (PEM) has a long history, starting with civil engineering projects and gradually expanding into a full-service engineering, procurement, and construction company. In this article, we look at PEM’s manufacturing standards, how it designs and builds heat exchangers, and how it meets the specific needs of its customers. We also provide an overview of other notable heat exchanger manufacturers in Iran and around the world. Continue reading to understand how PEM delivers reliable and efficient heat transfer solutions.

Petro Energy Man (PEM) – Heat Exchangers Manufacturers

Petro Energy Man Group (PEM) began its operations in 1975. In its early years, the company primarily focused on executing civil projects and providing related technical services — a path that laid the foundation for PetroMan’s strong and successful presence in the nation’s construction sector.

Strategic Development and Entry into Power Plant Industries

A major turning point in PEM’s growth came in 1976 with its entry into power plant projects. This milestone was achieved through strategic collaborations and the acquisition of technical expertise from international partners such as Brown Boveri and Asseck.

Through a deliberate strategy of targeted specialization, PetroMan systematically expanded its scope of operations over the following decades. By the mid-1990s, the company had successfully evolved beyond civil construction and established itself as a comprehensive EPC (Engineering, Procurement, and Construction) contractor, actively operating in key sectors including oil, gas, petrochemical, power generation, and cement industries.

Standardization and Current Capabilities

Today, Petro Energy Man stands as a capable and certified contractor, officially recognized by the Planning and Budget Organization of Iran. This formal accreditation serves as a testament to the company’s high capacity and technical expertise in delivering large-scale industrial megaprojects across the country’s infrastructure sectors.

By maintaining strict adherence to international quality standards, PetroMan has earned the lasting trust of a wide range of prominent domestic and international clients.

Strategic Network and Sustainable Competitive Advantage

Petro Energy Man plays a role that extends far beyond that of a traditional EPC contractor. The group has firmly positioned itself at the core of the professional network of heavy industries and the energy sector. Its active membership in key national institutions and associations stands as a testament to the company’s knowledge base, credibility, and enduring commitment to excellence. Strategic Memberships:

- Technical and Engineering Associations: Including the Mechanical Engineering Association, Engineering Standards Association, and the Technical Department of University of Tehran Alumni, ensuring continuous access to the latest innovations and scientific expertise.

- Professional and Contracting Bodies: Such as the Syndicate of Construction Companies and the Construction Services Industry Association, reflecting commitment to national execution standards and professional ethics.

- Industry Associations: To maintain a dynamic connection with current market demands and high-level industrial policymaking.

Human Capital and Project Management Infrastructure

PetroMan’s strength lies in its specialized human capital. The company’s internal team comprises over 200 experienced professionals across five key areas: management, engineering, supply chain, supervision, and execution, working synergistically.

This team, in close collaboration with four active subsidiary companies, forms an integrated and flexible operational structure. This organizational architecture enables Petro Energy Man to execute projects — regardless of scale or complexity — with the highest standards and guaranteed quality.

Distinguished Services

Another key advantage of Petro Energy Man lies in its provision of comprehensive pre-commissioning and full commissioning services. These services ensure that clients receive their facilities and projects fully operational, tested, and ready for production, thereby minimizing transfer risks and potential delays in the start of operations.

Heat Exchanger Standards Applied by Petro Energy Man

For specialized applications in the oil, petrochemical, and natural gas industries, Petro Energy Man adheres to the following ISO standards:

- ISO 16812: This standard applies to shell and tube heat exchangers, including heaters, condensers, coolers, and reboilers, used in the oil, petrochemical, and natural gas industries.

- ISO 13706: This standard defines the requirements and recommendations for the design, materials, fabrication, inspection, testing, and preparation for shipment of air-cooled heat exchangers used in oil, petrochemical, and natural gas applications.To ensure consistent quality and manufacturing processes, Petro Energy Man also complies with quality management standards:

- ISO 9001:2015: This international standard for quality management systems ensures stable product quality across heat exchanger production facilities. It is also applied in the manufacturing of plate heat exchangers.

- ISO 29001: This standard is a sector-specific quality management system designed for the oil, petrochemical, and natural gas industries.

Custom Heat Exchanger Fabrication

At PetroEnergy Holding, we focus on the design and fabrication of heat exchangers precisely tailored to the specific requirements of each industrial operation. This expertise covers a wide range of sectors, including chemical, pharmaceutical, biotechnology, food processing, and refineries. Each exchanger is designed and manufactured based on operational specifications, working conditions, and required thermal parameters to ensure both efficient heat transfer and the mechanical strength needed for demanding industrial environments.

The PetroEnergy engineering team, leveraging advanced simulation tools, specialized knowledge, and extensive practical experience, analyzes the unique needs and challenges of each system to provide the optimal design solution. This engineering approach ensures that the fabricated heat exchangers are not only thermally efficient but also durable and reliable over the long term.

Partnering with PetroEnergy provides access to precise, custom-engineered solutions that maintain the performance, efficiency, and safety of thermal systems over time while enhancing the stability of industrial operations.

How PEM Meets Customer-Specific Requirements

In general, the following stages are carried out at PEM, from design to execution, in the fabrication of a heat exchanger.

Data Collection for Equipment Design

In this stage, all necessary design information is gathered, which can be extracted from the process datasheets provided by the client. The collected data include:

- Specifications of the hot and cold fluids

- Operating temperatures and pressures for both hot and cold sides

- Thermodynamic properties of the fluids, including density, viscosity, and heat transfer coefficients

- Fouling factors for both hot and cold fluids

- Allowable pressure drops and flow velocities on the shell and tube sides, which must be considered during the design process

Process Simulation

At this stage, heat exchanger simulation is carried out, marking the beginning of the design phase. In addition to the thermal design, which determines the required heat transfer area and heat duty, a hydraulic simulation is also performed.

Using the constraints of fluid velocity and pressure drop for both the hot and cold sides, parameters such as tube length, inner diameter, and outlet temperatures of the fluids are calculated to achieve optimal performance and efficiency.

Mechanical Design

At this stage, based on the data obtained from the previous phase and in accordance with ASME Section VIII and TEMA (Tubular Exchanger Manufacturers Association) standards, key parameters within the heat exchanger design—such as shell thickness, tube thickness, flange and gasket dimensions, bolts and nuts, and other components—are calculated. Finally, the total equipment weight is determined.

Thorough knowledge and understanding of these design standards play a crucial role in achieving an optimized and reliable mechanical design.

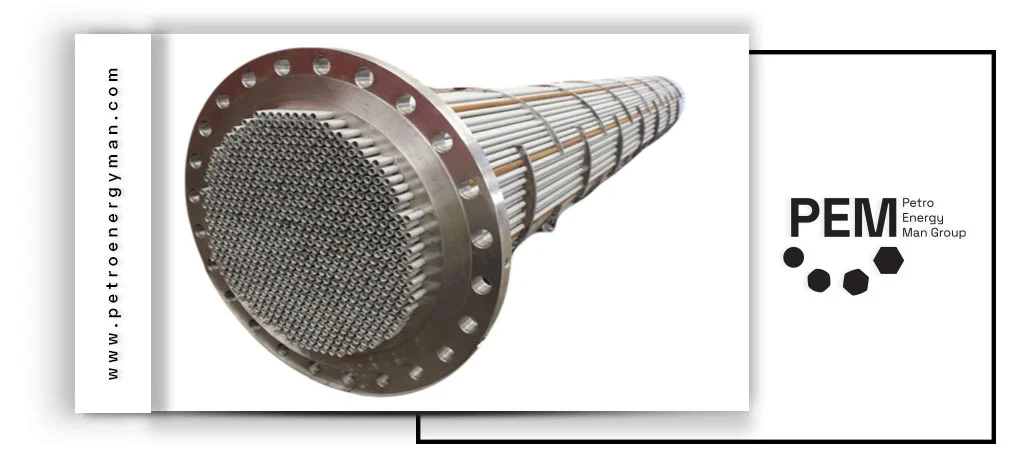

Drawing the Different Parts of the Heat Exchanger

Drawing the different parts of the heat exchanger for procurement and fabrication. These drawings include the following:

- General Drawing

- Tube Bundle Drawing

- Sectional Plan

- Detail Accessories

- Weld/NDT Map

- Tube Sheet Layout

Additionally, a Part List Drawing is prepared in which all components of the heat exchanger are identified with unique reference numbers. The entire process — from design to execution — for all heat exchangers and other fabricated equipment at PEM (Petro Energy Man) is carried out under a unified engineering procedure, with full coordination between the various engineering departments.

Other Heat Exchangers Manufacturers

Fateh Sanat Company: Fateh Sanat is one of the leading heat exchangers manufacturers in the petrochemical industry. The company plays a key role in optimizing heat transfer processes and minimizing energy loss through its high-quality products. Its heat exchangers are specifically designed to meet the demanding requirements of the petrochemical sector and are well-recognized in both domestic and international markets.

Nasim Mobadel Industrial Group: Founded in 1985, Nasim Mobadel Industrial Group has been a major producer of heat exchangers in Iran. Utilizing advanced equipment and modern technologies, the company manufactures and supplies a wide range of shell and tube and air-cooled heat exchangers to both local and foreign markets.

Sana Mobadel Tose’e Pars Company: Heat exchangers manufacturers such as Sana Mobadel Tose’e Pars Company play a crucial role in supporting industrial and petrochemical sectors. Sana Mobadel Tose’e Pars is an active manufacturer specializing in heat exchangers for petrochemical industries, boilers, and plate heat exchangers. Relying on the expertise of its skilled engineers, the company has significantly contributed to reducing the nation’s dependence on imported equipment.

By adhering to global standards and maintaining a commitment to continuous innovation, Sana Mobadel Tose’e Pars has earned the trust of domestic and international markets, solidifying its position as a leading industrial manufacturer in the region.

Fan Gostar Pouya: Fan Gostar Pouya Company is active in producing various types of heat exchangers for the petrochemical industry and air-cooled systems. With advanced technologies and high standards, the company’s products play a key role in heat transfer processes and in reducing energy loss in petrochemical operations.

Heat Exchanger Manufacturers Worldwide

Some of the leading heat exchanger manufacturers globally include:

- APV: A manufacturer of plate heat exchangers and a subsidiary of SPXFLOW. The company’s founder, Dr. Richard Seligman, is recognized as the inventor of the heat exchanger.

- Alfa Laval: A Swedish company and one of the leading plate heat exchanger manufacturers in the world.

- THT: A Chinese company specializing in the production of plate heat exchangers.

- Kelvion: A German brand established in 1920, formerly known as GEA. Kelvion is one of the world’s leading heat exchanger manufacturers.

- Danfoss: Danfoss is also recognized as a major global manufacturer of heat exchangers.

High Pressure Heat Exchanger Manufacturer

A high-pressure heat exchanger is a specialized equipment designed to operate under conditions where fluids flow at very high pressures. These types of exchangers play a critical role in industries where high-pressure boilers are an integral part of production or operational systems. The primary function of these units is to transfer heat between fluids at different temperatures safely and separately, ensuring no mixing occurs and maintaining stable performance under high pressure.

Designing and manufacturing high-pressure heat exchangers requires advanced technical expertise and the use of high-quality materials to withstand mechanical forces from internal and external pressures, while ensuring long-term stability and safety of the boilers.

Given the critical importance and design complexity of these units, selecting a reputable manufacturer for high-pressure heat exchangers is essential. In the following section, we outline the key factors to consider when choosing a reliable manufacturer for such equipment.

Key Factors in Choosing a High-Pressure Heat Exchanger Manufacturer

Selecting a manufacturer for high-pressure heat exchangers is a critical decision that directly impacts the efficiency, safety, and long-term operational costs of a project. Issues such as leak in shell and tube heat exchanger—which often result from poor design, inadequate material selection, or substandard fabrication—highlight the importance of choosing a qualified and experienced manufacturer with strong expertise and experience, reliable design and engineering capabilities, compliance with standards and certifications, advanced testing and inspection facilities, and the ability to deliver custom manufacturing solutions. To make the best choice, several key factors should be considered.

Compliance with Standards and Certifications

A reputable manufacturer should produce equipment in accordance with international standards for high-pressure systems. Standards such as ASME BPVC Section VIII for pressure vessel design and construction, TEMA for shell and tube heat exchangers, and API 660 for industrial heat exchangers in the oil and gas sector are among the most important. Obtaining recognized certifications demonstrates the manufacturer’s commitment to quality and safety.

Design and Engineering Capabilities

A leading manufacturer must have strong design and engineering capabilities. This includes using specialized heat exchanger design software such as HTRI and Aspen EDR to accurately simulate flow, temperature distribution, and pressure drop. These capabilities help optimize dimensions, reduce pressure losses, and enhance the thermal efficiency of the heat exchanger.

Testing and Inspection Facilities

The manufacturer should have adequate facilities to perform thorough post-production testing. These tests include hydrostatic pressure testing, leak tests, thermal performance testing, and non-destructive inspections (NDT) such as UT, RT, or PT to ensure the integrity of welds and the internal structure of the heat exchanger.

Custom Manufacturing Capability

Given the diverse needs of various industries, a manufacturer’s ability to design and fabricate custom heat exchangers based on specific technical requirements is a significant competitive advantage. This capability ensures that the heat exchanger aligns optimally with the operational system.

Expertise and Experience

Manufacturers with extensive experience in designing and producing high-pressure heat exchangers possess the knowledge and technical skills necessary to address complex engineering challenges. Their ability to provide specialized consultation and deliver customized designs for specific operational conditions is crucial. Companies with a proven track record of successful high-pressure heat exchanger projects in similar industries are generally more reliable and reputable.

Conclusion

Heat exchangers manufacturers such as Petro Energy Man (PEM) and other leading global companies play a vital role in industrial processes. In this text, we discussed PEM’s history, strategic development, compliance with international standards, detailed design and fabrication processes, and key services including commissioning. We also covered other notable Iranian and global manufacturers and their contributions to the industry, showing how these companies combine high-quality equipment with technical expertise to support complex industrial operations.

No comment