Heat exchanger design is a key and multidisciplinary field in chemical, mechanical, and energy engineering. In this article, we provide a comprehensive overview of the fundamental principles and practical methods involved in designing these systems, highlighting each critical stage of the process. These stages include defining process and design specifications, performing precise thermal and hydraulic calculations, adhering to mechanical design standards, and estimating construction and cost parameters. In addition, design calculation methods—such as determining Q, LMTD, and A—along with key factors affecting selection and performance, including fluid type, operational limitations, viscosity, and fouling potential, are thoroughly examined. Continue reading to gain a complete understanding of the technical, economic, and operational aspects of this essential engineering process.

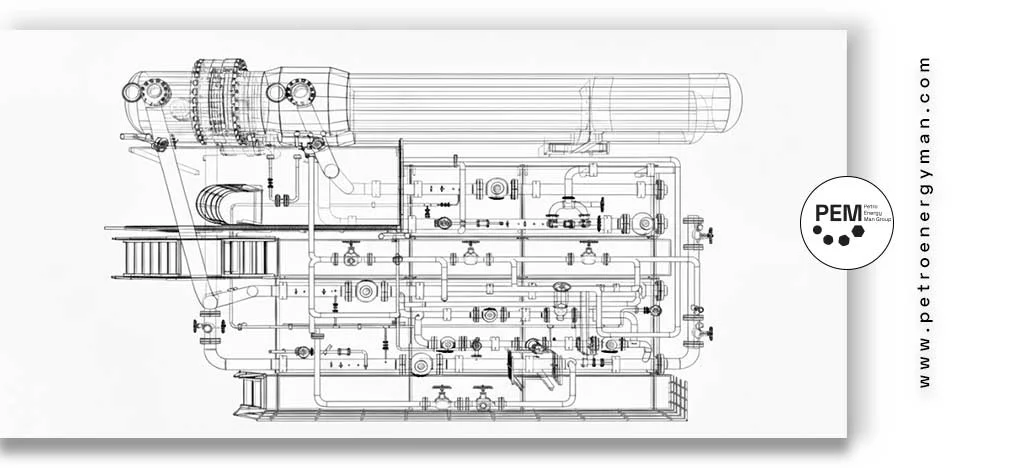

Principles and Methods of Heat Exchanger Design

The principles and methods of heat exchanger design involve several key stages, including defining process and design specifications, performing thermal and hydraulic design, conducting mechanical design, and calculating construction and cost parameters. Each of these steps plays a crucial role in ensuring the efficiency, durability, and economic feasibility of the heat exchanger system

Process and Design Specification

The main objective at this stage is to precisely define the thermal and operational requirements of the exchanger. This step includes determining the required heat transfer capacity and selecting the appropriate dimensions for optimal performance. The design engineer must have a thorough understanding of this process to ensure accurate calculations and efficient operation.

“You can explore more about the operation of heat exchangers on the Heat Exchanger Page.”

Thermal and Hydraulic Design

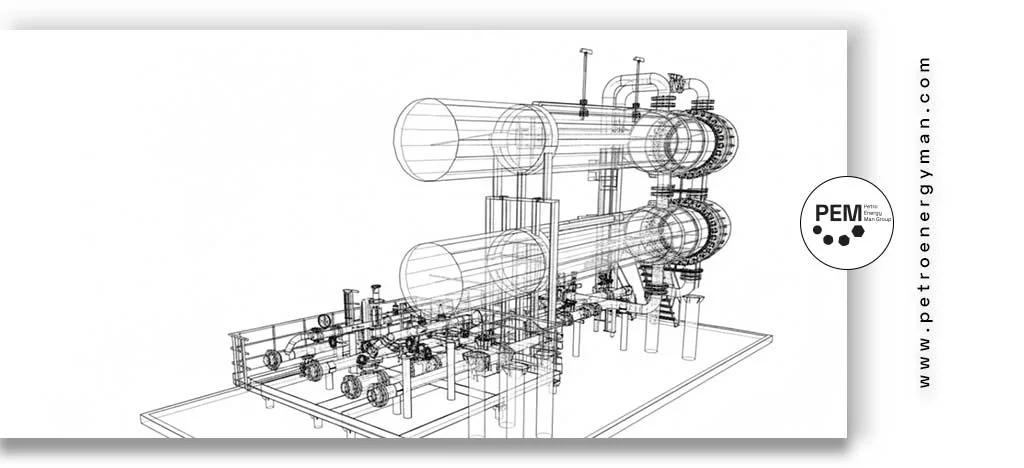

Heat exchanger design involves determining the heat transfer rate, evaluating fluid pressure drops, and establishing the overall size of the exchanger. This stage also includes assessing how the exchanger responds thermally to the incoming hot and cold fluids to ensure balanced performance.

Thermal Design

Thermal design focuses on calculating the required heat transfer area. By using thermal modeling, it predicts the outlet temperatures of each fluid stream in the exchanger. The primary goal is to maximize the heat transfer rate and enhance the overall efficiency of the system.

Hydraulic Design

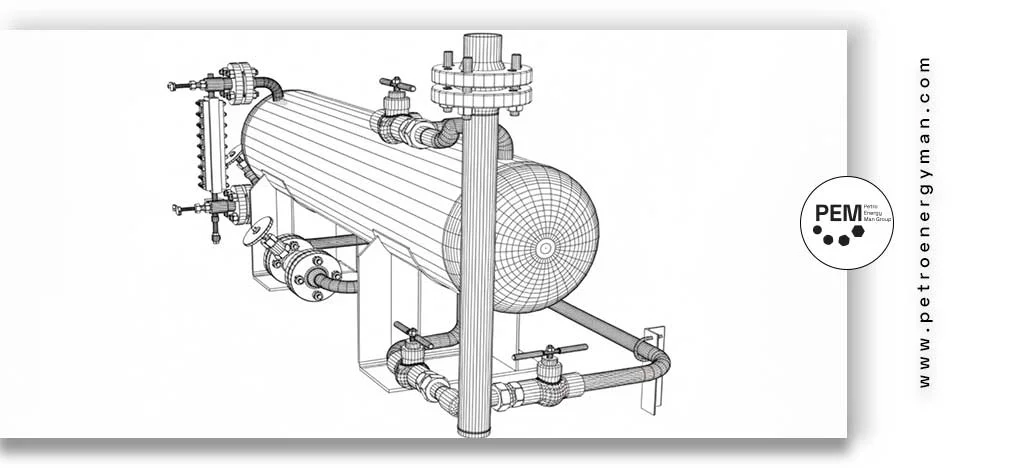

Hydraulic design examines pressure drops and fluid flow behavior within the exchanger. In hydraulic systems, heat exchangers play a crucial role in controlling oil temperature and maintaining system efficiency. Optimizing the exchanger’s geometry can significantly reduce pressure losses, leading to lower pump energy consumption and improved operational performance.

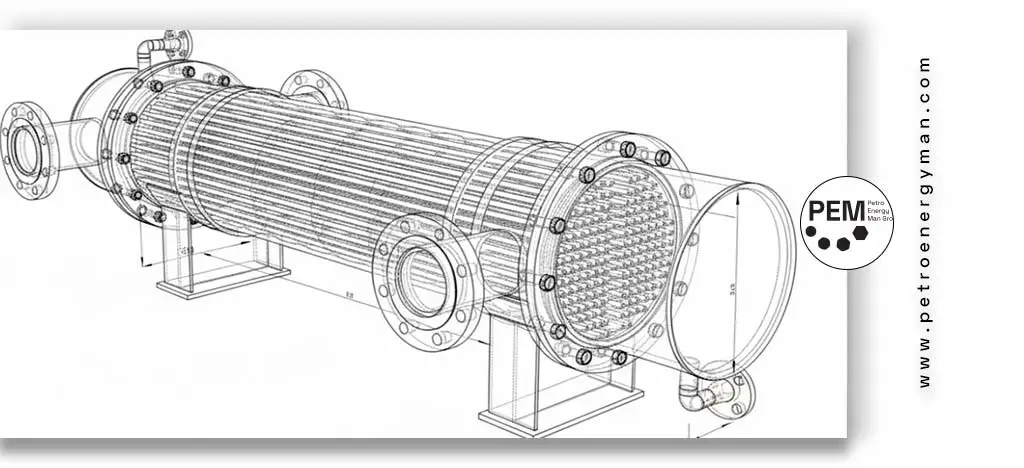

Mechanical Design

Mechanical design of a heat exchanger involves selecting materials, wall thicknesses, and other structural components to ensure the strength and durability of the system. This stage also examines mechanical design parameters and highlights the differences between a simple pressurized vessel and a shell-and-tube heat exchanger. All mechanical designs must comply with relevant standards, such as TEMA.

Cost and Fabrication Calculations

In the heat exchanger design process, cost and fabrication calculations are crucial. They include estimating the expenses for raw materials, manufacturing, maintenance, and the overall lifecycle of the system. Accurate cost assessment ensures both economic feasibility and efficient resource allocation. You can visit the Heat Exchanger Pricing page for detailed information on costs and the key factors affecting the selection of this equipment.

Performance Factors and System Optimization

The performance of heat exchangers depends on multiple factors that can enhance system efficiency and reduce costs. Proper geometric design, including the use of fins and optimized arrangements, improves heat flow and shortens heat transfer time. Fluid velocity and type significantly influence the heat transfer rate, while minimizing pressure drop saves energy and material. Additionally, using nanofluids and porous media can boost heat transfer efficiency and reduce the required exchanger length. Tools like pinch analysis and optimization algorithms help identify optimal operating points and lower energy costs for precise and efficient system performance.

“petroenergyman provides expert services in designing and manufacturing heat exchangers, fully complying with technical standards and operational requirements. For consultation, you can contact 02157423.”

Heat Exchanger Design Calculations

To perform heat exchanger design calculations, several steps must be followed, including selecting the type of exchanger, calculating the heat transfer rate, determining the overall heat transfer coefficient, computing the heat transfer surface area, and evaluating other related parameters.

Determining the Heat Transfer Rate (Q)

To calculate the heat transfer rate, if the mass flow rate and the inlet and outlet temperatures of the fluids are known, the following relationship can be used:

Q = ṁ · cp · (Tin − Tout)

where:

- ṁ: mass flow rate (kg/s)

- cp: specific heat capacity (J/kg·K)

- Tin, Tout: inlet and outlet temperatures of the fluid (°C or K)

Determining the Effective Temperature Difference

In the calculation process of a thermal transfer unit, for systems where the two fluids flow in countercurrent or parallel directions, the LMTD (Logarithmic Mean Temperature Difference) method is commonly applied to evaluate the effective temperature difference and ensure accurate heat transfer estimation.

ΔTm = (ΔT1 − ΔT2) / ln(ΔT1 / ΔT2)

where:

- ΔT1 = Th,in − Tc,out

- ΔT2 = Th,out − Tc,in

Th and Tc are the temperatures of the hot and cold fluids, respectively.

Overall Heat Transfer Coefficient (U)

The overall heat transfer coefficient is determined based on the material of the exchanger, the type of fluids, and their flow characteristics. Usually, this value is either provided or estimated using mechanical and convective heat transfer correlations.

Heat Transfer Surface Area (A)

In heat exchanger design, the required heat transfer surface area is calculated using the overall heat transfer coefficient and the effective temperature difference. This ensures the system achieves the desired heat transfer while optimizing efficiency and material usage.

A = Q U · ΔTm

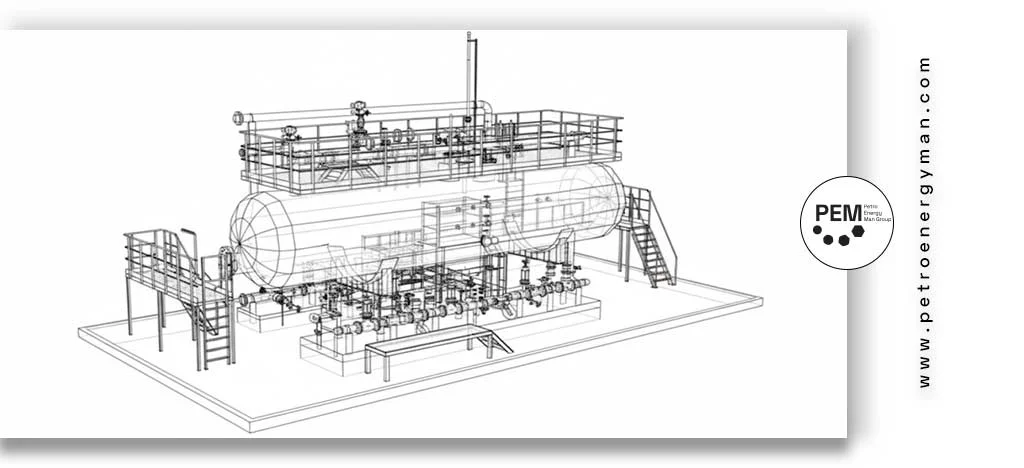

Heat Exchanger Dimension Design

Based on the calculated heat transfer area and the type of thermal transfer unit, the physical dimensions of the system—such as tube length, number of tubes, diameters, and other specifications—are determined. Accurate geometric data and performance parameters are essential to ensure that the final design achieves optimal efficiency and reliable operation.

Heat Exchanger Design: Selection and Design

Selecting and designing an appropriate thermal transfer system is a complex process that requires careful consideration of a range of technical, economic, and operational factors. Ignoring any of these aspects can result in poor performance, increased costs, or even system failure.

Fluid Type and Properties

The type of fluids and their physical and chemical properties are among the most critical factors in selecting and designing a thermal transfer system. These characteristics directly affect the heat transfer mechanism, material selection, and even the choice of exchanger type, ensuring efficient and reliable operation.

Fluid Phase (Liquid/Gas/Phase Change):

- Liquid-Liquid: For heat transfer between two liquids, shell-and-tube or plate exchangers are commonly used.

- Gas-Gas: Air-to-air exchangers or compact heat exchangers are typically applied for this purpose.

- Gas-Liquid: Shell-and-tube exchangers are widely used in these cases.

- Phase Change (Evaporation/Condensation): When one of the fluids undergoes a phase change (such as in condensers or evaporators), the design becomes more complex, requiring specific heat transfer surfaces or optimized arrangements. The exchanger structure depends on whether a fluid is evaporating or condensing.

Viscosity, Corrosivity, and Fouling Potential

- Viscosity: High-viscosity fluids (e.g., heavy oils) generate higher pressure drops and lower heat transfer rates. This may require special design considerations to optimize flow and reduce pressure loss.

- Corrosivity: Corrosive fluids require the use of corrosion-resistant materials such as stainless steel, titanium, or other specialized alloys.

- Fouling Potential: Some fluids tend to form deposits on heat transfer surfaces, reducing efficiency and increasing pressure drop. In heat exchanger design, the system should allow for easy cleaning (e.g., plate-type exchangers) or include measures for fouling resistance, such as selecting optimal flow velocities.

Operational Limitations

These limitations define the main framework for designing a thermal transfer system and are essential for safe and optimal performance.

Operating Temperature and Pressure

Temperature Range: The exchanger must be capable of withstanding the inlet and outlet temperatures of the fluids. Selecting appropriate materials to tolerate high (or low) temperatures and prevent thermal stresses caused by temperature differences is very important.

Operating Pressure: The maximum operating pressure of the fluids determines the wall thickness and the type of connections for the exchanger components. The exchanger must have sufficient strength to withstand both operational and test pressures.

Required Heat Load

The amount of heat that must be exchanged between the fluids determines the overall size of the exchanger and the required heat transfer surface area.

Conclusion

Heat exchanger design as a multifaceted process requires the seamless integration of thermal, hydraulic, and mechanical analyses. The success of this design depends on simultaneously addressing critical challenges such as fluid properties (fouling and corrosivity), material selection, and operational limitations. Therefore, achieving long-term efficiency and reliability is only possible by maintaining a precise balance between superior technical performance, economic feasibility, and system safety.

No comment