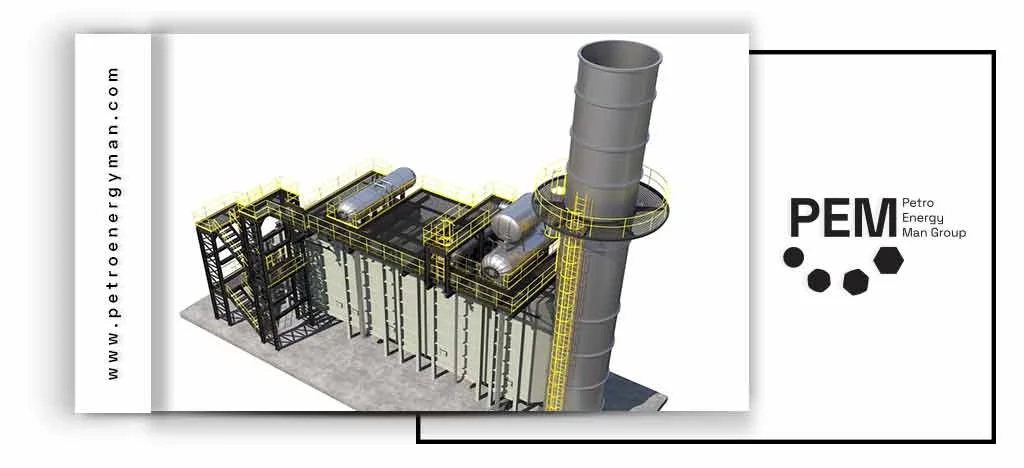

What is an HRSG (Heat Recovery Steam Generator)?

HRSG (Heat Recovery Steam Generators) are industrial boilers that utilize waste heat from exhaust gases to produce saturated or superheated steam. They can also be designed with supercritical pressure to supply steam for specific steam turbines. The main feature of these boilers is the recovery of heat from hot gases, which improves efficiency and reduces operating costs.

HRSGs can be manufactured with capacities ranging from 0.5 to 10 tons of steam per hour for combined heat and power (CHP) systems, and 10–60 t/h for industrial applications and small gas turbines. For power plants and large gas turbines, the steam generation capacity can range from 60 to 700 t/h or even higher. The steam produced by HRSGs can be used in industrial processes for process heating or to drive a steam turbine for electricity generation in combined cycle systems.

Design of Heat Recovery Steam Generator

HRSG design is one of the key stages in improving the efficiency of combined cycle power plants and industrial units. In this type of boiler, the heat from hot exhaust gases produced by gas turbines or other thermal processes is recovered to generate steam at the required pressure and temperature. Proper design involves selecting the configuration, determining heat transfer surfaces, and optimizing the flow of gas and working fluid to extract the maximum amount of energy from the exhaust gases.

Since the composition and temperature of flue gases vary across industries, the design and selection of boiler components must be adapted to the characteristics of the incoming gases—whether high, medium, or low temperature. Therefore, understanding the main components and their functions, along with analyzing the properties of the inlet gas, plays an important role in comprehending the overall performance of the system. The following sections examine the various components of the HRSG and the types of exhaust gases it utilizes.

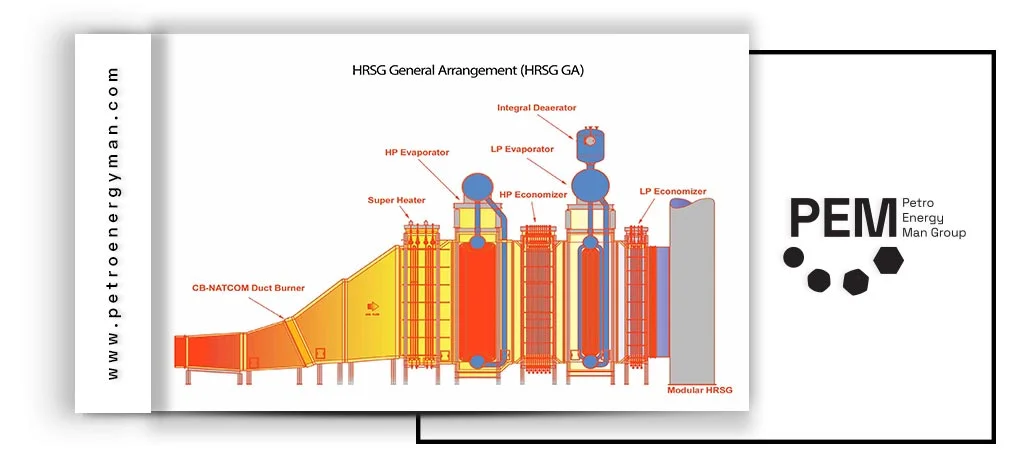

Components of a Heat Recovery Steam Generator

In order to transfer heat from the hot gas to the water (the working fluid on the cold side), heat recovery steam generators (HRSGs) consist of numerous components, which are briefly reviewed in this section. Upon entering the HRSG, the flue gas is uniformly distributed over the boiler’s heat transfer surfaces through a diverging duct. After passing through the heat transfer surfaces and reducing its temperature, the gas exits the boiler through the chimney.

The heat transfer surfaces in HRSGs are divided into packages known as modules, which include tubes, headers, fittings, tube sheets, and more. The types of modules in a heat recovery boiler are as follows:

Evaporator

The evaporator is the most important heat transfer section of the boiler, where water changes phase from liquid to steam. It provides the largest heat transfer surface area because the majority of heat exchange occurs here.

Superheater

The saturated steam produced in the evaporator passes through the superheater, where—at nearly constant pressure—it absorbs additional heat and transforms from saturated steam into superheated steam.

Economizer

After the gas passes through the superheater and evaporator, it still retains a considerable amount of energy. The economizer recovers part of this energy by transferring it to the boiler feedwater (BFW). This improves boiler efficiency and reduces the energy required to preheat the feedwater.

Reheater

The reheater allows reheating of high-pressure steam returning from the first section of the steam turbine, which increases turbine efficiency and power output. In reheat-type HRSGs, this section is typically located before the duct burner and serves as the first heat exchange surface exposed to the exhaust gases.

The steam produced in the evaporator enters the steam drum.

The steam drum not only distributes steam and water properly inside the boiler but also dries the wet steam (from the evaporator) using internal demister pads, sending dry steam to the superheater.

The outlet temperature of the superheater is controlled by a desuperheater, which prevents excessive temperature fluctuations in the steam.

In dual-drum HRSGs, there is also a water drum, which receives water through downcomer tubes and distributes it into the evaporator tubes.

Other Major Components of Heat Recovery Steam Generator

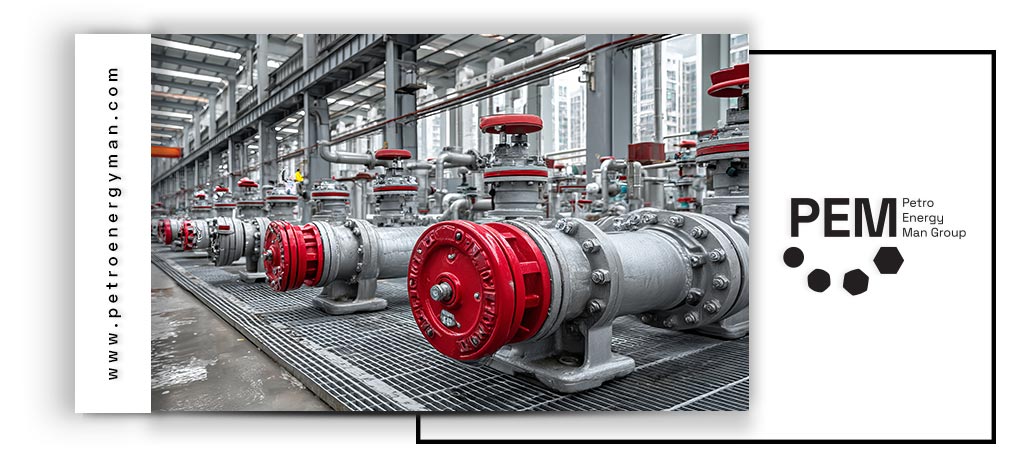

- Control and Instrumentation System: Comprises pressure, temperature, and water level sensors, gas flow sensors, and automatic controllers to maintain safe and stable boiler operation.

- Deaerator: Removes oxygen and other dissolved gases from the feed water to protect the system from corrosion.

- Flue Gas Control Dampers: Regulate the flow of flue gas and control boiler pressure. A guillotine damper at the inlet duct manages gas entry, while a second damper in the chimney assists startup, increases gas pressure, and improves the heat transfer coefficient. Enhancing the heat transfer coefficient reduces the required surface area and overall boiler weight.

- Blowdown System: Removes dissolved salts and sediment from the water. Continuous blowdown maintains proper salt concentration, while intermittent blowdown clears accumulated deposits in the drum.

- Cladding and Insulation: Thermal insulation is applied to prevent heat losses and increase overall efficiency.

- Metal Supports: Provide a stable foundation for boiler installation.

- Feed Water System: Includes pumps, tanks, control valves, and filters. Water from the deaerator is pressurized and directed toward the economizer for efficient heat recovery.

Types of Flue Gas Inlet to HRSG

Nowadays, there is a wide range of flue gas qualities and temperatures in various industries. In general, industrial flue gases can be categorized based on their temperature into the following three main groups:

| Flue Gas Type | Range | Unit |

|---|---|---|

| High Temperature | 650-1650 | ℃ |

| Medium Temperature | 300-650 | ℃ |

| Low Temperature | 50-300 | ℃ |

The use of high-temperature flue gases in heat recovery steam generators (HRSGs) requires extensive research and redesign of the boiler in order to employ materials with higher thermal resistance. High-temperature flue gases are typically emitted from metal melting furnaces (nickel, zinc, copper, steel, and aluminum), cement kilns, incinerators, and glass melting furnaces. The waste heat from these sources can be effectively recovered and used for steam generation through heat recovery boilers.

Flue gases with medium temperatures are widely used in the HRSG industry. They are mainly exhausted from gas turbines, diesel engines, and some heat treatment furnaces. The typical flue gas temperature ranges are 370–650 ℃ for gas turbines, 300–600 ℃ for diesel engines, and 400–650 ℃ for heat treatment furnaces. Most combined cycle HRSGs are connected to gas turbines, which fall into this category.

Recovering heat from low-temperature sources is often not economically feasible. However, when heat recovery is required, innovative methods are used to enhance heat transfer from low-temperature fluids. One such method is the Organic Rankine Cycle (ORC), which operates based on the low boiling points of organic fluids (such as toluene). These fluids evaporate at lower temperatures, making it possible for the vapor to enter a steam turbine. Nevertheless, specific operational conditions and special turbines are required in such systems, which increase both the cost and the overall complexity of the process.

Advantages and Challenges of HRSG

Heat Recovery Steam Generators (HRSGs) play a key role in improving energy efficiency and reducing fuel consumption in power plants and industrial units by utilizing the waste heat from exhaust gases. These systems not only enable the production of steam at various temperatures and pressures but also reduce environmental pollutants and make optimal use of thermal resources, making them a sustainable and economical solution.

Despite their significant advantages, designing and operating HRSGs comes with certain challenges. High initial costs, the requirement for adequate installation space, and dependence on the primary heat source are among the main considerations. A thorough review of the benefits and challenges helps in better planning and making optimal decisions when implementing these boilers.

Advantages of Heat Recovery Steam Generators

- Increased Energy Efficiency: The main feature and advantage of a heat recovery steam generator (HRSG) is its ability to utilize the waste heat from flue gases to produce steam, which leads to reduced fuel consumption and improved energy efficiency.

- Reduced Fuel Consumption: Producing steam using waste heat significantly lowers the fuel consumption of an industrial facility or power plant. This, in turn, reduces the operational costs of the boiler for fuel supply. In fact, without generating this steam via an HRSG, package boilers—which consume fuel—would be required.

- Steam Production at Multiple Pressure Levels: Depending on the design, HRSGs can be single-pressure, double-pressure, or triple-pressure. This allows steam to be supplied for various processes or for multi-pressure steam turbines.

- Reduced Environmental Emissions: Combustion of fossil fuels generates pollutants such as CO, NOx, and SOx. HRSGs help reduce these emissions by lowering fossil fuel consumption.

- Ability to Utilize Multiple Heat Sources: HRSGs can be redesigned to use various heat sources, including flue gases from gas turbines, waste incinerators, different industrial furnaces, and acidic gases.

- Steam Production Control with Supplementary Firing: Using a supplementary burner allows control over steam capacity when the gas turbine is not operating at full capacity, compensating for lower flue gas temperature and flow rate.

Disadvantages and Challenges of Heat Recovery Steam Generator

High Initial Cost:These systems handle low-temperature exhaust gases, which increases boiler size and material usage. Although initial investment is higher than in package boilers, long-term fuel savings reduce operating costs. Petroman minimizes design and production expenses through advanced engineering and optimized heat transfer efficiency.

Installation Space:Due to lower flue gas temperatures, a larger heat transfer surface is required for effective heat exchange. This involves more tubes, finned tubes, and greater boiler length. Petroman optimizes the layout using advanced software and proprietary design tools to reduce the required installation space.

Dependence on Heat Source:These systems rely on exhaust gases from upstream processes or gas turbines. If the source is shut down, gas supply stops and operation is affected. Petroenergyman ensures continuous operation with auxiliary burners that provide hot gases during shutdowns for autonomous performance.

Types of HRSGs

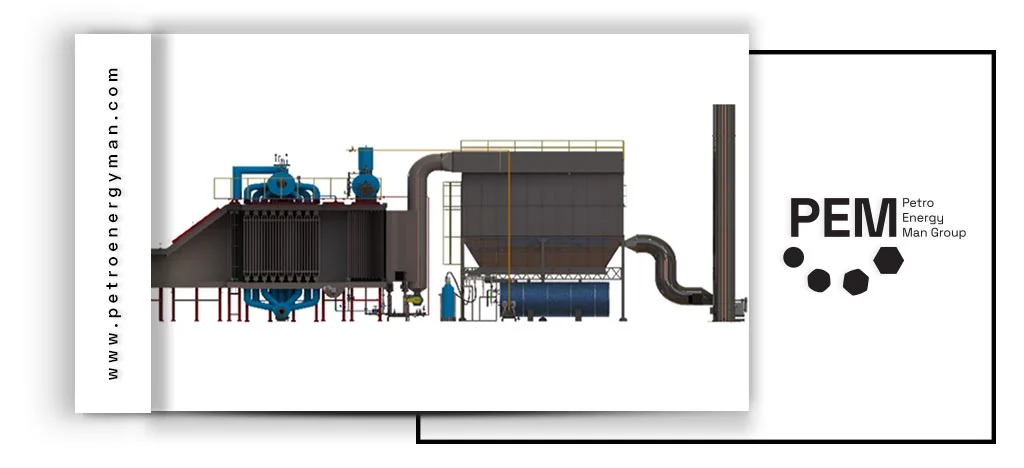

Heat Recovery Steam Generators can be classified based on several design and operational parameters such as module arrangement, fluid circulation type, presence of supplementary burners, steam pressure levels, and the number of drums. Each classification is explained in detail below.

Based on Tube Arrangement

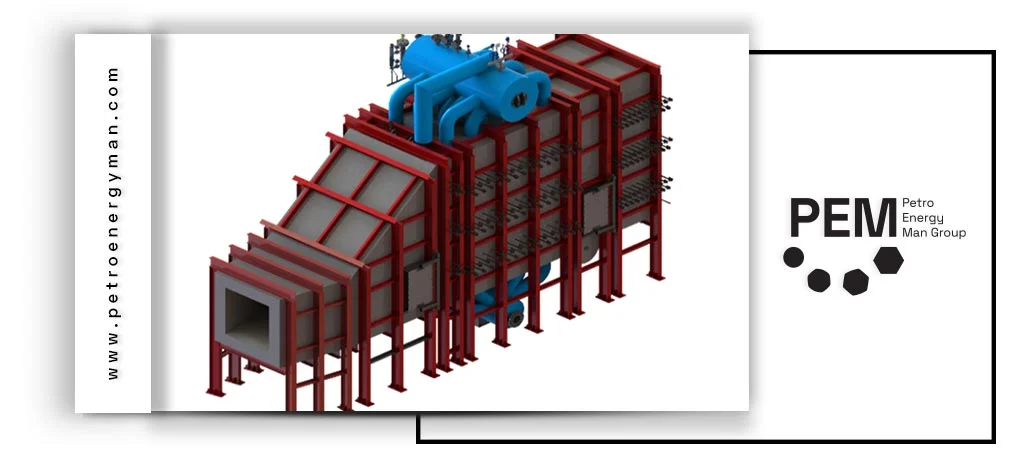

HRSGs are commonly categorized into three types according to the orientation of their tube bundles: horizontal, vertical, and once-through.

Horizontal Type:In this configuration, the modules (tube bundles) are positioned vertically while the exhaust gas flows horizontally across them. This is one of the most common arrangements due to its easier maintenance and effective water drainage. A disadvantage compared to vertical-tube designs is the need for about 10% more installation space. However, it offers the advantage of allowing indoor installation.

Vertical Type:In this design, the modules are arranged horizontally, and the flue gas flows vertically through the tube bundles. Unlike the horizontal configuration, where natural circulation is common, the vertical design generally requires forced circulation. This is because the horizontal placement of tubes reduces static head, making it necessary to use a circulation pump.

Once-Through Type:A key limitation of both horizontal and vertical configurations is the presence of a steam drum, which restricts steam production capacity and increases startup time. The once-through design eliminates the drum, enabling higher steam capacities and removing the pressure limitations of drum-type systems. However, since there is no drum to separate water and steam, these boilers require feedwater of significantly higher purity.

Based on Water Circulation

Heat recovery steam generators (HRSGs) are classified into two types based on the type of fluid circulation: natural circulation and forced circulation. Fluid circulation in a boiler represents the driving force that moves the water-steam mixture within the boiler. This driving force can be provided naturally by the density difference of water in the downcomer and riser tubes, along with the thermal head generated. In this case, the boiler is referred to as a natural circulation boiler. In HRSGs with natural circulation, no circulation pump is required.

If the thermal head is insufficient, a circulation pump must be used to move the fluid, in which case the boiler is called a forced circulation boiler.

Based on the Presence of Supplementary Burners

HRSG systems may include a supplementary burner, commonly designed as a duct burner, installed in the inlet duct before the superheater. This burner helps compensate for variations in the exhaust gas flow and temperature coming from the gas turbine. When the system is equipped with this additional combustion unit, it is referred to as a Fired type; if the burner is not included, it is known as an Unfired type.

Based on Steam Pressure Levels

One of the advantages of heat recovery steam generators (HRSGs) is the ability to produce steam at multiple pressure levels. These boilers can be designed as single-pressure, producing one steam output; double-pressure, producing two steam outputs at different pressure and temperature levels; or even triple-pressure.

HRSG Manufacturers

HRSG manufacturing is carried out by several well-known international companies, including GE Vernova, Vogt Power International, Siemens, Babcock & Wilcox, Alstom, John Cockerill, Thermax, and other reputable global producers. In Iran, a number of companies are also engaged in the design and production of these boilers. Among them, Petroenergyman Company stands out by leveraging technical expertise and skilled professionals to provide innovative designs and meet a wide range of customer requirements.

Conclusion

HRSG is a widely used industrial boiler designed to recover waste heat and convert it into steam. It can be manufactured in different configurations, pressure levels, and layouts, with the possibility of supplementary firing. By utilizing waste heat, this system produces saturated and superheated steam, leading to significant fuel savings and reduced pollutant emissions.

No comment