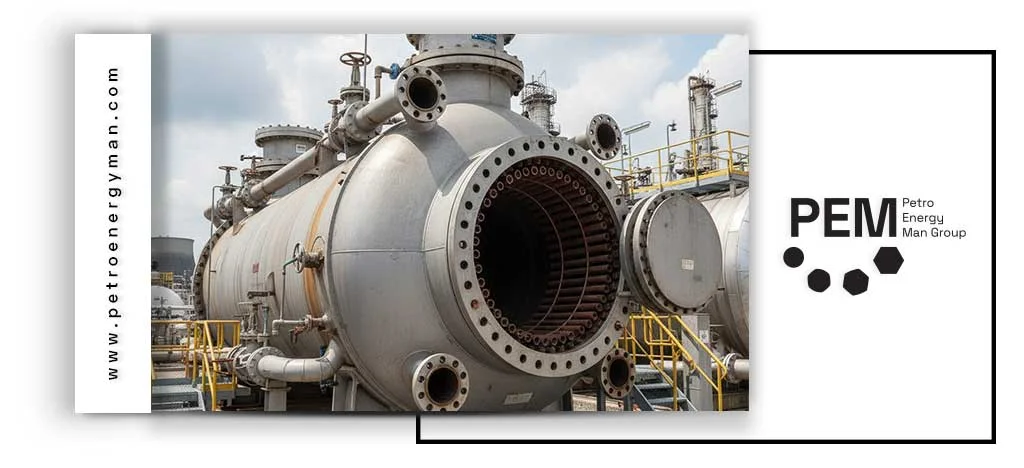

The advantages and disadvantages of shell and tube heat exchangers are among the key topics in evaluating the performance of industrial heat transfer equipment. In this article, we will examine the main technical and operational advantages of these exchangers, such as high resistance to pressure and temperature, effective management of thermal stresses, long service life, and flexibility in design and material selection. In addition, we will analyze their limitations, including large dimensions, slow thermal response, fouling issues, and maintenance difficulties. For a deeper understanding of the real-world performance and strengths and weaknesses of this industrial device, stay with us until the end of this article.

Advantages of Shell and Tube Heat Exchangers

The superiority of this type of heat exchanger stems from its robust design, high adaptability to strict industrial standards, and engineered mechanisms that ensure optimal thermal performance and long-term operational cost efficiency. This section exclusively analyzes the key technical and operational benefits of shell and tube exchangers.

High Resistance to Temperature and Pressure

One of the most significant advantages of shell and tube heat exchangers is their ability to operate safely and stably under high-temperature and high-pressure conditions. From a mechanical engineering perspective, the cylindrical shape of the shell provides the best geometry for withstanding heavy operational pressures. This structure is specifically designed to resist internal stresses and is manufactured under well-known international standards such as TEMA and ASME. As a result, these exchangers demonstrate exceptional durability, stability, and reliability in harsh industrial environments.

Shell and tube heat exchangers support a wide range of operating conditions and can function efficiently at extremely high temperatures and pressures without performance degradation. In newer generations, the use of innovative designs such as the Compact Header Design has significantly reduced pressure limitations. This configuration can withstand pressures up to approximately 1000 bar (14,500 PSI)—a capacity that meets almost all requirements of high-pressure process industries.Moreover, these exchangers maintain excellent heat transfer capacity even at elevated temperatures, ensuring stable and efficient thermal performance.

The high-pressure resistance feature is not only a technical advantage but also a major safety benefit from an engineering standpoint. In designs that incorporate compact headers, the volume of fluid contained within the equipment is considerably smaller compared to traditional configurations. This reduction in confined volume directly lowers the amount of stored energy within the pressurized fluid. Consequently, in the unlikely event of a rupture or leak, the released energy is much lower—significantly reducing the risk of explosion or fire. This safety advantage is especially critical in applications involving flammable or toxic fluids, where maintaining process safety is a top priority.

Thermal Stress Management (Differential Expansion)

When a high temperature difference (ΔT) exists between the shell-side and tube-side fluids—which can lead to differential expansion and induce stress on the tube sheet or tubes—STHEs (Shell and Tube Heat Exchangers) address this issue with specific designs:

- Floating Head Design: In cases where the temperature difference between the hot and cold fluids is very high, floating head designs (types S, T, P, W) are employed. In this configuration, one tube sheet is floating and fully accommodates the thermal expansion of the tube bundle, thereby reducing thermal stress.

- U-Tube Design: This design, requiring only a single tube sheet, is the most cost-effective structure. The U-shaped bend of the tubes allows free thermal expansion, making the exchanger suitable for high ΔT applications.

- Leak Prevention: In fixed tube sheet exchangers, the absence of flange connections on the fixed side minimizes the risk of leakage. Additionally, under high design pressures or in the presence of corrosive fluids, welded connections (strength welds) can be used to ensure complete sealing of the tubes to the tube sheet.

Operational Life and Durability

Shell and tube heat exchangers, when properly maintained, can achieve an operational life of over 40 years. Their long lifespan results from the flexibility in material selection and the structural robustness of the design. To accommodate the corrosive nature of tube-side or shell-side fluids, these units can be constructed from a wide range of corrosion-resistant materials, including stainless steel, copper, and specialized alloys.

High Reliability Against Leakage

Another structural advantage is their high reliability against leakage, which is essential for processes handling hazardous or toxic fluids. In configurations using a fixed tube sheet, welding the shell to the tube sheet eliminates flange connections, which are typically weak points and sources of leaks. This significantly reduces the risk of fluid leakage and enhances process safety.

Compatibility with Corrosive and Viscous Fluids (Material Selection)

STHE design offers high flexibility in choosing construction materials to handle corrosive or aggressive fluids. It is possible to design and manufacture the exchanger using specialized materials such as stainless steel, copper, brass, aluminum, or nickel, depending on the fluid type and corrosion resistance requirements.

Specifically, in highly corrosive environments, titanium is an ideal material for tube construction due to its exceptional corrosion resistance (e.g., in acidic media or seawater) and high thermal stability.

Optimization of Heat Transfer Surface per Unit Volume

The high efficiency of shell and tube heat exchangers (STHEs) arises from their internal geometry. Using a large number of small-diameter tubes inside the shell significantly increases the total heat transfer surface area (A) within a compact volume. This increase in contact surface directly enhances the heat transfer rate (Q) according to fundamental thermodynamic principles, enabling effective and high-efficiency heat transfer in a relatively small-sized device.

Design Flexibility and Compatibility with Challenging Fluids

One of the greatest operational advantages of STHEs is their ability to handle fouling-prone, viscous fluids, and fluids containing suspended solids. Due to the larger tube diameters, STHEs are less sensitive to fouling compared to plate heat exchangers and can accommodate higher amounts of impurities and particles without blockage.

In cases where the shell-side fluid velocity is very high or contains suspended solids (which can cause erosive corrosion), impingement baffles are installed at the inlet to reduce tube wear.This compatibility with challenging fluids, such as crude oil, allows STHEs to operate in critical processes where other heat exchangers would quickly become clogged and fail—making them essential in oil and petrochemical industries.

STHEs also offer considerable flexibility in geometric design. Engineers can choose different flow arrangements (parallel, counterflow, crossflow, or hybrid) on both the shell and tube sides to best match process requirements such as heat capacity, pressure drop, or desired pressure levels.

Disadvantages of Shell and Tube Heat Exchangers

Despite their numerous advantages, shell and tube heat exchangers (STHEs) are not without limitations. Some of the most notable disadvantages include:

Large Size and Space Requirements

One of the most obvious limitations of STHEs is their large physical size. To achieve the same heat transfer capacity, shell and tube exchangers require significantly more space and footprint compared to more compact designs.

Slower Thermal Response

Due to their higher thermal mass and the larger volume of fluid flowing inside the shell and tubes compared to more compact designs, STHEs generally exhibit slower thermal response. This means more time is required to reach a stable operating temperature, which can be a drawback in processes that require rapid and precise temperature control.

Fouling and Reduced Efficiency

If the shell-side or tube-side fluid contains suspended particles or fouling agents, deposits can form on the tubes, increasing thermal resistance. In fixed tube sheet designs, access to the external tube surfaces is limited, making fouling issues even more significant.

Difficulty in Cleaning U-Tube and Fixed Tube Sheet Designs

The ease of cleaning STHEs depends heavily on the TEMA configuration, and two common designs have notable limitations:

- Fixed Tube Sheet: In this design, the tube sheet is welded to the shell, preventing removal of the tube bundle. Consequently, mechanical cleaning is limited, and fouling removal must primarily be done using chemical cleaning methods.

- U-Tube: While this is the most cost-effective design, the tight U-bend at the tube ends prevents the passage of mechanical cleaning tools such as brushes or water jets, necessitating chemical cleaning.

Conclusion

This text reviewed the advantages and disadvantages of shell and tube heat exchangers. The main advantages include high resistance to pressure and temperature, flexibility in material selection to handle corrosive fluids (e.g., titanium), and the ability to manage thermal stresses using U-tube and floating head designs. However, disadvantages such as large physical size, relatively slow thermal response, and significant limitations in mechanical cleaning for common designs (fixed tube sheet and U-tube) must be carefully considered during the engineering process.

No comment