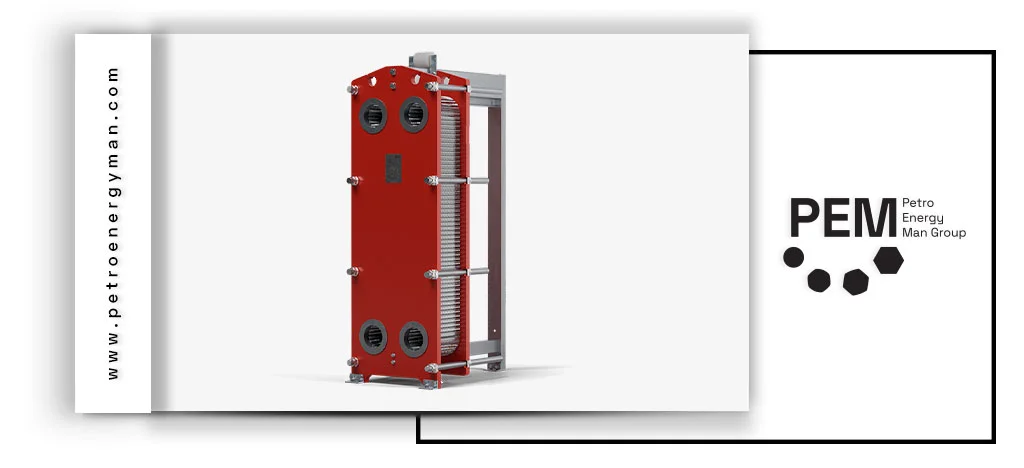

A plate heat exchanger is designed to transfer heat between two fluids, whether liquid or gas. Its structure is composed of a series of thin, corrugated metal plates arranged systematically. This design allows efficient heat transfer between the fluids without direct contact. Features such as compact design, high efficiency, and adaptability to various conditions have made plate heat exchangers widely used across different industries.

What is a Plate Heat Exchanger?

A plate heat exchanger (PHE) is a key component in heating systems and building boiler rooms. It is used to transfer heat between two fluids, which can be gases, liquids, or even two-phase mixtures. The operating principle is that hot and cold fluids enter from opposite directions and flow alternately between thin corrugated plates, enabling effective heat transfer. The plates are arranged parallel to each other, forming alternating channels for the fluids. The corrugated design increases turbulence and improves thermal efficiency. Heat is transferred from the hot fluid to the plates via conduction and then from the plates to the cold fluid via convection.

To gain a complete understanding of how heat exchangers operate in various industries, we recommend reading the article Heat Exchanger which provides a comprehensive overview.

Main Components of Plate Heat Exchangers

Plate heat exchangers consist of several essential components, each playing a critical role in ensuring proper operation and efficiency. Understanding these parts is important for maintenance and troubleshooting.

- Frame (Casing): The frame serves as the structural support and protective shell. It typically consists of two steel plates—one fixed at the front and the other movable at the back. The heat transfer plates are clamped between them with tightening bolts. The frame also directs fluid flow to the inlet and outlet nozzles.

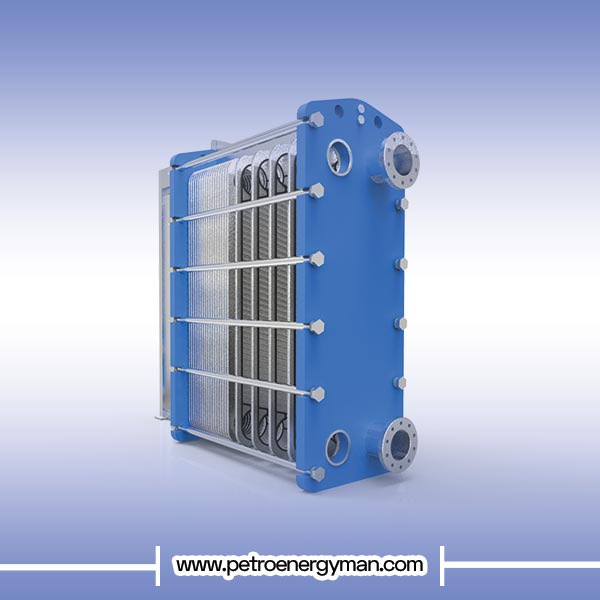

- Plates: These are the heart of the plate heat exchanger, providing the main heat transfer surface. Plates are often embossed or corrugated to create turbulence and improve performance. Their material depends on the fluid type and operating conditions, commonly stainless steel, titanium alloys, or nickel.

- Gaskets: In gasketed plate heat exchangers, gaskets act as seals to prevent mixing of hot and cold fluids. Made from polymers or elastomers (such as NBR, EPDM, or Viton), they sit in grooves on the plates and guide fluid flow into the correct channels.

- Tightening Bolts and Guide Bars: Bolts compress the plates together to prevent leaks. The top and bottom guide bars ensure proper alignment of the plates during assembly and maintenance.

Types of Plate Heat Exchangers

Plate heat exchangers are classified into four main categories based on plate sealing and application:

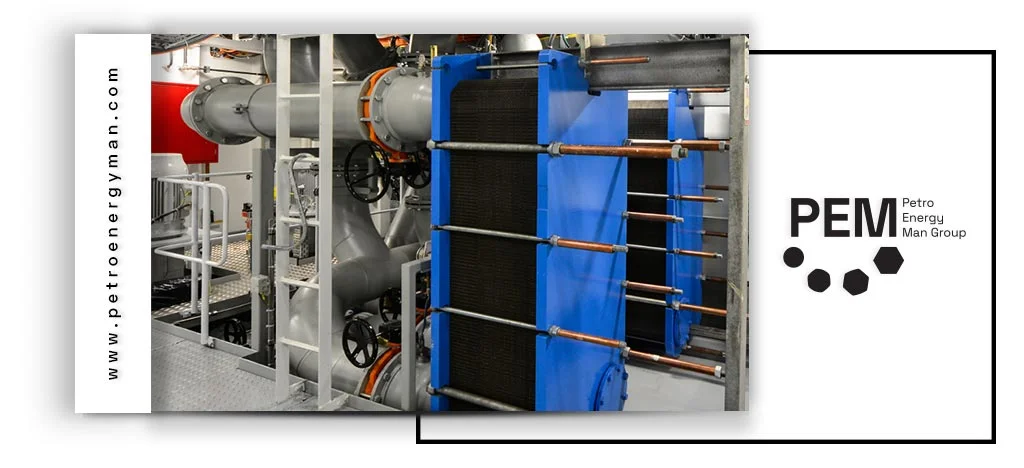

- Gasketed Plate Heat Exchangers (GPHE):Equipped with high-temperature-resistant gaskets, these units are ideal for applications requiring periodic cleaning, since the plates can be dismantled easily.

- Brazed Plate Heat Exchangers (BPHE):Plates are permanently joined through brazing, creating compact, efficient units capable of handling higher pressures and temperatures, with no gaskets required.

- Welded Plate Heat Exchangers:Plates are fully welded together (e.g., Compabloc models). These are designed for heavy-duty industrial environments requiring high resistance to corrosion and pressure.

- Semi-Welded Plate Heat Exchangers:Some plates are welded, while others are sealed with gaskets. This hybrid design allows easier access for cleaning certain channels while maintaining high strength and sealing performance.

Competitive Advantages of Plate Heat Exchangers

- Compact Design & Lightweight: The stacked plate arrangement provides a very high heat transfer surface area in a small footprint, making them lighter and more space-efficient than equivalent shell-and-tube exchangers.

- Scalability (Modularity): In gasketed models, capacity can be easily adjusted by adding or removing plates, offering flexibility for changing process demands.

- Cost-Effectiveness: Exceptional thermal efficiency and reduced energy and maintenance costs make PHEs a long-term economic investment.

Efficiency of Plate Heat Exchangers

The corrugated plate design induces turbulence, significantly increasing the heat transfer coefficient. This turbulence minimizes the thermal boundary layer, ensuring effective heat exchange between hot and cold fluids. Such efficiency is crucial in applications where maximizing heat transfer is essential.

Guide to Choosing a Plate Heat Exchanger

Selecting the right plate heat exchanger requires careful consideration of engineering, operational, and economic factors:

Selecting the right plate heat exchanger requires a careful review of engineering, operational, and economic factors. These factors not only affect performance but also influence the efficiency and lifespan of the equipment. For a deeper understanding of the economic aspects and cost considerations of heat exchangers, you can read the article “Comprehensive Analysis of Factors Influencing heat Exchanger price.”

Technical & Performance Considerations

- Operating Pressure & Temperature: Gasketed PHEs are suitable for moderate conditions (up to ~25 bar, 200°C), while brazed types can handle higher levels (up to ~40 bar, 250°C). Fully welded models withstand extreme environments (up to 1000°C).

- Fluid Type: For fluids with suspended solids or impurities, gasketed units are preferable due to ease of disassembly and cleaning. Brazed and welded units are best suited for clean fluids.

- Required Efficiency: PHEs deliver high efficiency due to turbulence and large surface area.

Maintenance Considerations

- Gasketed PHEs are easy to maintain and clean, making them ideal for applications prone to fouling.

- Brazed and welded PHEs, being non-detachable, offer no internal cleaning options but provide greater durability.

Causes of Fouling in Plate Heat Exchangers

- Fluid Quality: Suspended solids, impurities, and minerals in water are the main contributors to fouling.

- pH Levels: The acidity or alkalinity of the fluid affects scaling and corrosion.

- Viscosity: High-viscosity fluids increase fouling risks.

- Surface Roughness: Rough surfaces encourage deposit accumulation.

- High Temperatures: Promote mineral precipitation and scaling.

- Low Flow Rates: Allow deposits to settle and accumulate.

- Temperature Differences: Large temperature gradients accelerate fouling.

- Material Composition & Surface Finish: The surface properties of exchanger materials also affect fouling rates.

Conclusion

A plate heat exchanger, due to its exceptional efficiency, compact design, and high flexibility, has become one of the most important heat transfer devices in modern industries. This type of exchanger not only occupies less space and is lightweight, but also resists fouling more effectively due to the turbulence it generates. Selecting the appropriate type of exchanger should be done carefully, based on technical and economic considerations, to ensure optimal performance and longevity.

No comment