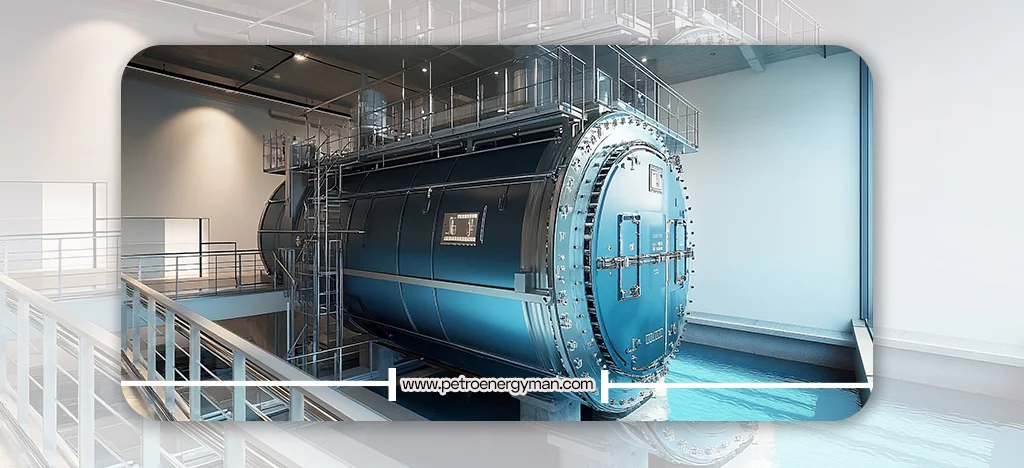

What is a Water-Tube Boiler?

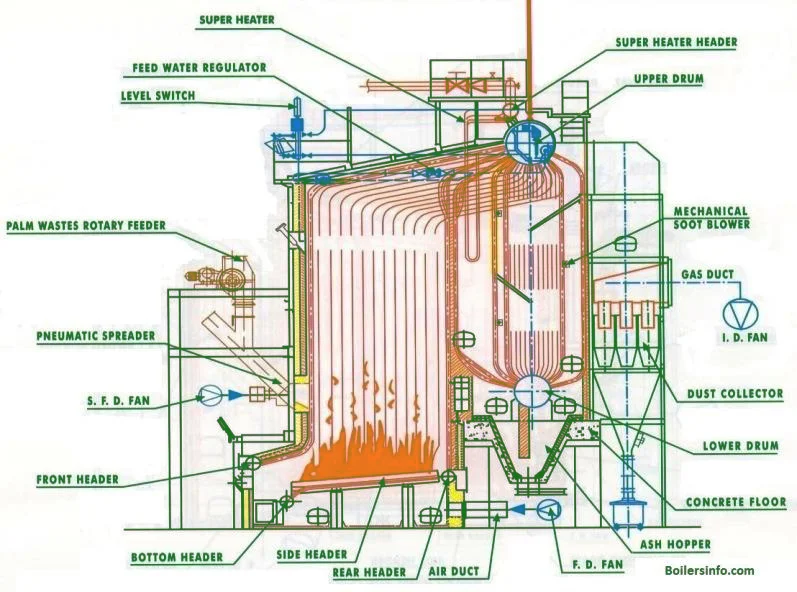

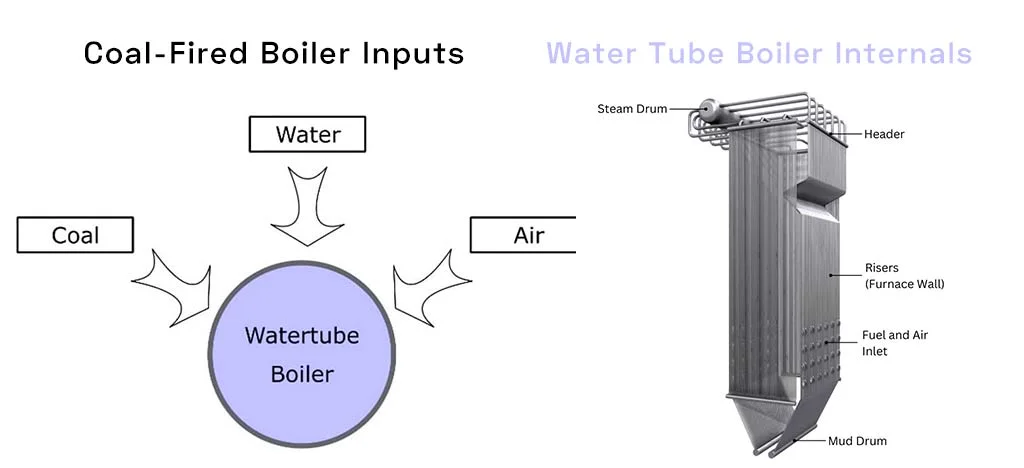

A Water-tube boiler is a type of industrial steam boiler in which water flows inside the tubes while the hot combustion gases pass outside the tubes. As water enters the tubes, it absorbs heat from the combustion gases and is converted into steam. In this system, heat transfer takes place between the cold fluid (water) inside the tubes and the hot fluid (combustion gases) outside the tubes, resulting in the production of steam at high pressure and temperature. The operating pressure range of watertube boiler is typically 10–80 bar, and the temperature range is 180–480 ℃.

Types of Watertube Boilers

Water-tube boilers are designed and manufactured in different configurations to meet spatial limitations, various steam requirements (capacity, pressure, temperature), ease of installation and maintenance, and other customer needs.

| Classification Type | Category | Description |

|---|---|---|

| Working Fluid | Water | Most watertube boilers use water as the working fluid to generate steam. |

| Fuel Type | Single or Multi-fuel | Can operate using natural gas, diesel, or a combination of fuels. |

| Customized Fuels | Can be redesigned to use process gases, hydrogen, or heavy fuels. | |

| Circulation Type | Natural Circulation | Flow is driven by the density difference between water and steam. |

| Forced Circulation | Circulation is maintained using pumps for better flow control. | |

| Structure | O-Type | Dual flue gas paths, balanced weight distribution, used in portable boilers. |

| A-Type | Compact structure with two gas passes, used for limited space setups. | |

| D-Type | Single flue gas path, high efficiency, commonly used in industries. | |

| Application | Package Boiler | Used in factories and industries for process steam; small to medium capacity. |

| Utility / Hanging Boiler | Large boilers used in power plants to generate turbine steam. | |

| HRSG (Heat Recovery Boiler) | Recovers heat from gas turbines or industrial exhaust gases. | |

| Other Classifications | Tube Arrangement | Boilers can have horizontal or vertical tube configurations. |

| Installation Type | Can be modular, skid-mounted, or field-erected. | |

| Design Standard | Manufactured under standards such as ASME or EN 12952. |

Classification Based on Working Fluid

The working fluid of Watertube Boilers is typically water.

Classification Based on Fuel

Conventional watertube may be designed as single-fuel or multi-fuel units, most commonly capable of using natural gas and diesel oil. Petroenergyman also offers redesign solutions for watertube boilers to operate with process gases, hydrogen, and heavier fuels to meet specific customer requirements.

Classification Based on Fluid Circulation

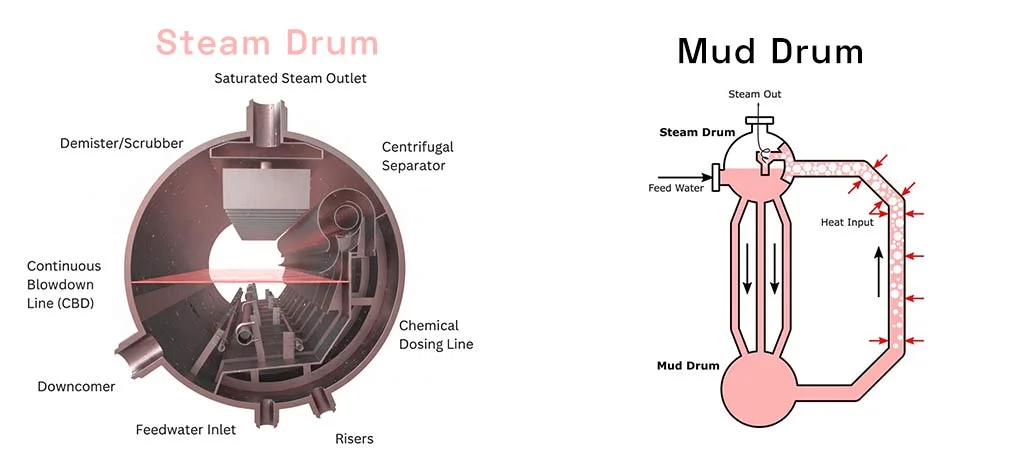

Water circulation in a boiler refers to the driving force that moves the water–steam mixture. This driving force may be natural circulation, created by the density difference between water in the downcomers and risers along with the thermal head. When natural circulation is insufficient, a circulating pump is required, in which case the boiler is referred to as a forced circulation boiler.

Classification Based on Structure

In O and A types, the flue gases exit the furnace located in the center, turn 180 degrees, and are then divided into two streams entering the tube banks. One of the advantages of these designs is better weight distribution, making them suitable for portable boilers.

However, for general industrial applications, these two designs are nearly obsolete, with the D-type being preferred due to its higher thermal efficiency. In D-type boilers, widely used across industries, the entire flue gas flow after leaving the furnace passes into the convective heat transfer section. The advantage of the D-type is the elimination of flow distribution issues across dual paths.

Classification Based on Application

Water-tube boilers can be categorized into three main types:

- Package Boilers

- Hanging (Utility) Boilers

- Heat Recovery Steam Generators (HRSG)

Utility boilers are typically used in power plants to supply steam for turbines, featuring very high capacity and pressure. Package boilers generally have lower capacity and pressure and are mainly intended for internal process steam consumption in industries. HRSG boilers are often employed in gas power plants to recover heat from the hot exhaust gases of gas turbines, but they are also used in other industries to recover energy from high-temperature waste gases. A common feature among all three types is that water flows inside the tubes while hot gases pass around them.

Other Classifications

Beyond the above, water tube boilers may also be classified by tube arrangement, installation method, and construction standards such as EN 12952 or ASME. The diversity in watertube designs allows manufacturers to deliver optimized solutions for specific industrial needs.

Advantages and Disadvantages of Water-Tube Boilers

Watertube boilers offer

significant advantages that make them the ideal choice for many heavy-duty

industrial and power generation applications. However, like any technology,

they also pose challenges, for which petroenergyman provides tailored solutions based

on years of experience in boiler manufacturing.

Advantages of WaterTube Boilers

High pressure and capacity, high steam generation rate, safety under high pressures, high efficiency, ease of maintenance, variety in design and construction, the ability to use different fuels, and controllability are among the advantages of water tube . These advantages will be explained in detail in

High Pressure and Capacity

One of the most important benefits of water tube boilers is their ability to produce steam at very high pressures and capacities. Package water-tube can deliver steam up to 80 bar and 180 t/h, while utility hanging boilers can reach up to 160 bar and capacities well above 180 t/h.

Safety at High Pressures

Unlike fire-tube boilers, which store a large volume of water in a single shell and require strict safety precautions to prevent explosions, water-tube boilers contain smaller volumes of water distributed across multiple tubes. In case of tube rupture, only a small amount of steam and water is released, significantly reducing explosion hazards.

High Efficiency

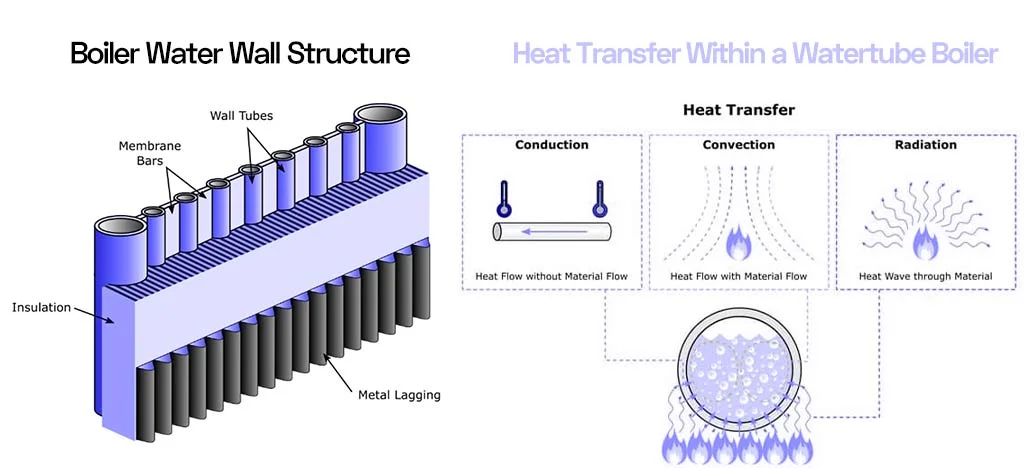

The design of water-tube boilers enhances heat transfer between hot gases and the working fluid. With proper insulation, thermal efficiency can exceed 92%, translating into lower fuel consumption and reduced operating costs.

Ease of Maintenance

These boilers are designed to provide accessibility for inspection, maintenance, and modifications.

Flexibility in Design and Construction

Flexible tube arrangement and overall configuration

allow the manufacture of boilers optimized for specific industrial

requirements, including spatial constraints. In addition to standard designs,

petroenergyman offers custom redesign services using specialized expertise

Fuel Flexibility

Water tube boilers can operate on a wide range of fuels, including natural gas, heavy fuel oil, solid fuels, biomass, and hydrogen, enabling industries to optimize fuel choices based on availability and cost.

Controllability

These boilers can operate with multiple burners, either independently or in parallel, and are often integrated with Programmable Logic Controllers (PLC) for precise load management and reduced greenhouse gas emissions.

Challenges of Water Tube Boilers

The water-tube boiler has certain drawbacks or challenges, including manufacturing and installation quality requirements, high initial cost, and the need for continuous inspection and monitoring.

Manufacturing and Installation Quality

Due to their complex design, watertube boilers require high-quality raw materials to ensure both thermal conductivity and mechanical strength. Precise fabrication and optimized design are key challenges.

In PetroMen-designed water-tube superheater tubes are commonly manufactured from SA240 T22, while evaporator tubes are made from SA210 A1, providing enhanced heat transfer, higher efficiency, and durability under thermal stress. These material selections may vary depending on project requirements.

Additionally, the large dimensions of watertube make transportation difficult, requiring on-site assembly, which adds to project complexity and scheduling. PetroMen addresses this by applying documented Fabrication, Shipping, and Erection Procedures, along with well-defined schedules to facilitate the process.

High Initial Cost

The complexity of manufacturing, the need for advanced engineering materials, and precision production processes significantly increase the capital investment compared to fire-tube boilers. PetroMen mitigates this by optimizing material use and employing advanced insulation methods, such as Ceramic Fiber, to reduce both capital and operating costs.

Need for Continuous Monitoring and Control

The operation, maintenance, and servicing of these boilers require advanced technical expertise due to their engineering complexity. Personnel must undergo continuous training, and systems must be carefully monitored. For this reason, Petromen boilers are covered by a full warranty for up to two years, during which the company not only provides the necessary operational training but also guarantees boiler performance for up to 200,000 Equivalent Operating Hours (EOH).

Design Principles of Water-Tube Steam Boilers

The design of water-tube steam boilers is a complex and precise engineering process aimed at meeting the specific needs of customers while ensuring safe and efficient operation

Initial Design Steps and Considerations

The design process begins with the collection of initial data regarding the required steam output, outlet steam temperature, and operating system pressure. Based on this information, key parameters such as the approximate dimensions of the boiler, burner capacity, fan capacity, pump power, tanks, and other preliminary specifications are determined. Additionally, the available space for installation and the required footprint of the boiler system are defined. This approach ensures that the boiler delivers the final steam output while meeting the specific operational requirements of each project.

Key Design Parameters

Once the initial requirements are established, designers focus on detailed technical parameters. These include design pressure, design temperature (for various sections such as the shell, tubes, plates, and fins), flue gas inlet temperature, effective radiant surfaces, and minimum thickness requirements for pressure parts (drums, tubes, piping, and tanks).

A critical parameter in water-tube boilers is the Circulation Ratio (CR). This ratio indicates the level of water recirculation in the system to ensure adequate water-to-steam conversion and prevent overheating of the tubes.

Role of Standards and Software

To guarantee safety, reliability, and efficiency, boiler design must comply with internationally recognized codes and standards. The ASME Boiler and Pressure Vessel Code provides practical and safety guidelines for the construction and testing of steam boilers, while NFPA standards (National Fire Protection Association) are applied to mitigate combustion-related hazards. Additional national and international standards may also be applied.

Advanced engineering software such as ANSYS, FireCAD, PPSD, PDMS, EES, SolidWorks, Catia, and AutoCAD are used to facilitate and improve design precision.

Efficiency Enhancements in Design

Various methods are applied during the design stage to increase the overall efficiency of steam boilers. The higher the efficiency, the more steam can be produced with lower fuel consumption and reduced energy losses.

The extensive heat transfer surface area in water-tube boilers—due to water flowing inside tubes surrounded by hot gases—significantly improves efficiency. In general, the efficiency of watertube boilers can reach 92–95%.

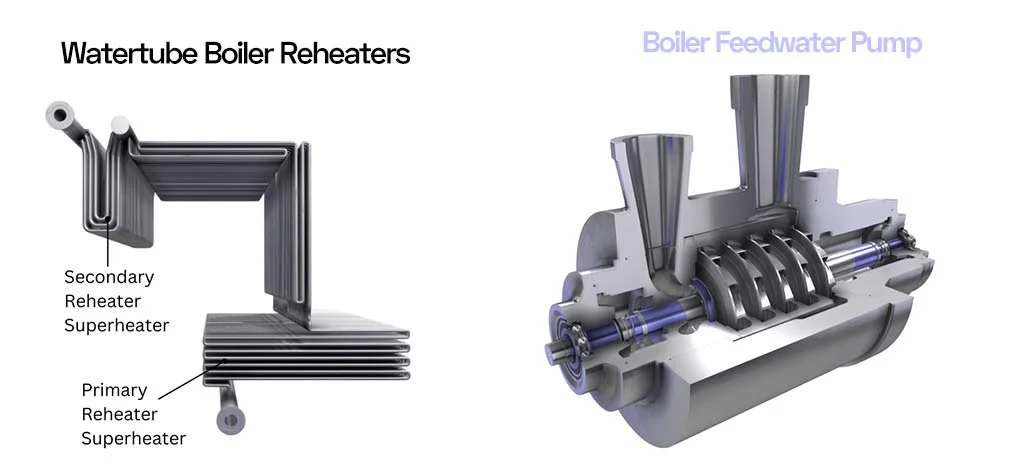

Additional auxiliary equipment such as economizers (for preheating feedwater), superheaters (to increase saturated steam temperature to superheated levels), increased furnace pressure (to improve heat transfer), and deaerators (for removing dissolved gases in water) can further enhance performance. Tube arrangement and layout are also carefully optimized to maximize heat transfer.

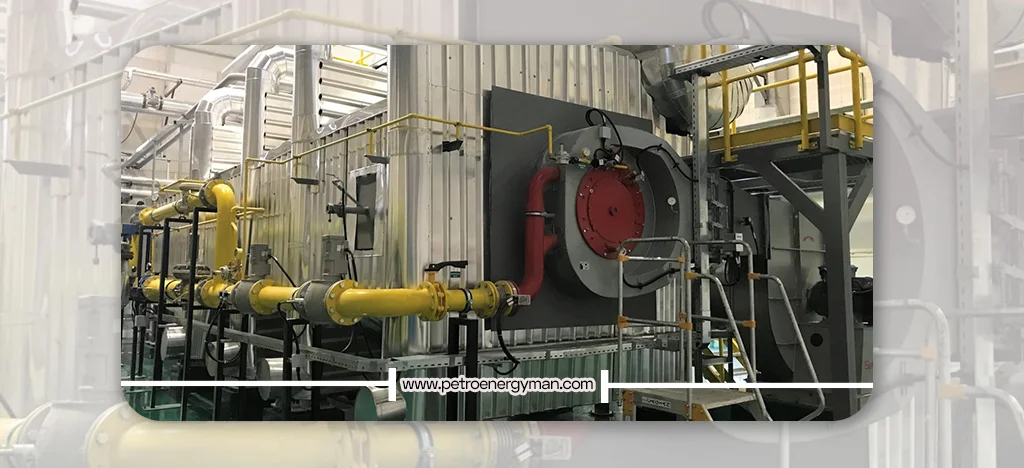

Manufacturing Process of Water-Tube Boilers

The construction process of a water tube boiler covers all stages from material preparation to full commissioning, with each step explained in detail below.

Key Fabrication

Processes

- Raw Material Procurement: Main components include seamless alloy steel tubes, steam and water drums (large heavy steel parts), the furnace (combustion chamber), and auxiliary parts such as superheaters, economizers, and control/safety systems, sourced from the highest-quality materials available both domestically and internationally.

- Cutting and Drilling: Steel plates are cut using high-precision CNC cutting machines. Drum drilling is carried out in several stages according to Petromen’s proprietary drilling procedures.

- Rolling and Bending: Cut steel plates are rolled and bent into the required shapes. Water tubes may also undergo bending processes as necessary.

- Main Assembly: Bent and cut steel parts are assembled with high precision.

- Welding: Pressure parts such as drums and joints are welded using automated Submerged Arc Welding (SAW) to ensure maximum weld integrity and quality. Tube-to-drum connections are typically achieved by tube expansion (rolling), and for high-pressure systems or potential tube leaks, seal welding is added. Fin welding on economizer tubes is done with High-Frequency Welding, ensuring metallurgical bonding and improved heat transfer efficiency.

Welders must hold valid certifications according to international standards such as EN287. - Insulation and Cladding: After the structural assembly is complete, the boiler body is insulated with high-grade refractory ceramic fiber insulation to minimize energy losses and improve thermal efficiency.

Quality Control and

Testing

- Weld Inspections: All welds are rigorously inspected by authorized inspectors from the Iranian National Standards Organization using non-destructive testing (NDT) methods such as Radiographic Testing (RT), Ultrasonic Testing (UT), Penetrant Testing (PT), and Visual Testing (VT).

- Hydrostatic Testing (Cold Test): Upon completion, boilers are hydrostatically tested with water at 1.5 times the design pressure to ensure strength and safety under high-pressure conditions.

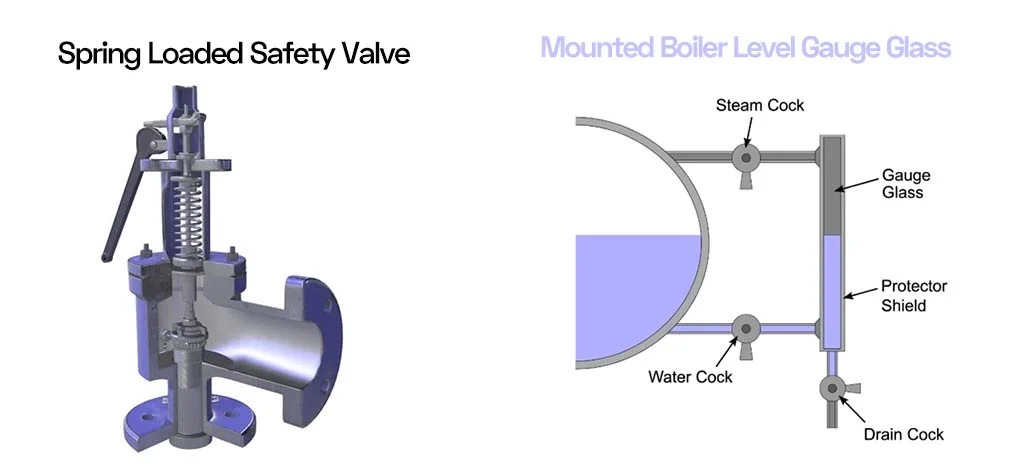

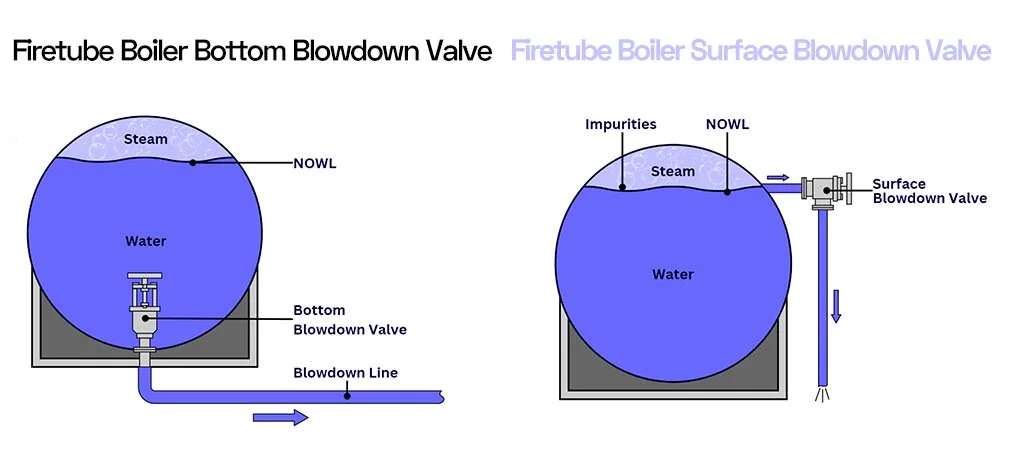

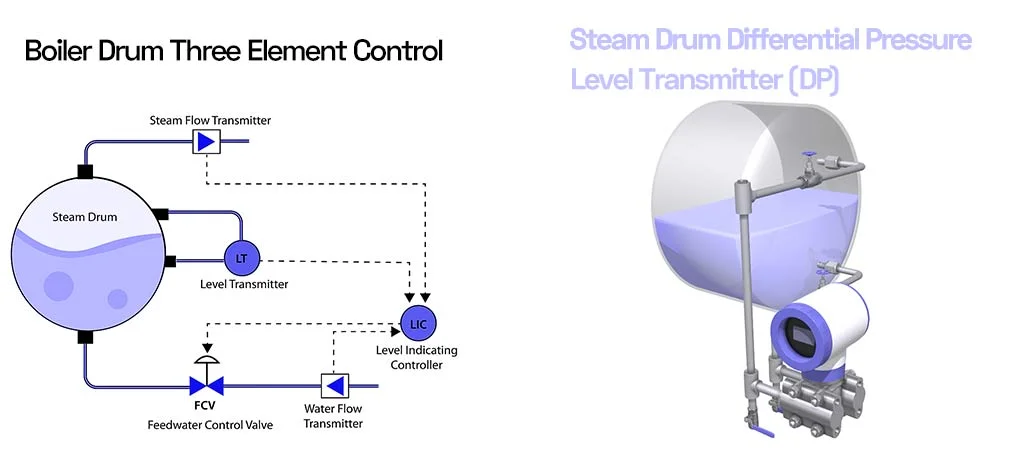

- Auxiliary Equipment Installation: Essential equipment such as burners, feedwater pumps, water level controls, pressure switches, safety valves, discharge valves, feed valves, and electrical/control panels are installed and tested for proper operation.

- Initial Commissioning (Hot Test): For small-capacity boilers, initial commissioning may be carried out at the factory, but for large-capacity units, it is performed on-site by specialized engineers. In most watertube boilers, hot testing occurs after final installation.

How a Water Tube Boiler Works?

Water-tube boiler: Feedwater, after passing through preheating equipment such as the economizer, enters the boiler drum. From the drum, water flows through downcomer tubes to the heated sections located in the furnace and along the path of hot flue gases. Inside these tubes, water gradually absorbs heat from combustion and transforms into a mixture of water and steam. This mixture, due to its lower density, rises through riser tubes back to the drum. Within the drum, steam separates from the remaining water. The generated steam at the top of the drum is collected, while the leftover water re-enters the circulation cycle. This continuous water and steam circulation forms the basis of stable boiler operation. When dry or superheated steam is required, the steam leaving the drum is directed to the superheater, where its temperature rises and becomes ready for use in turbines or industrial processes. Precise control of pressure, temperature, and water flow ensures fast startup, high safety, and stable performance under varying loads.

Applications of

Water-Tube Boilers

Watertube boilers, due to their unique ability to generate steam at high pressure and temperature along with excellent thermal efficiency, are widely used in a broad range of heavy industries and critical processes.

Power Generation Plants

Watertube boilers are widely used in thermal and combined-cycle power plants. The steam produced drives steam turbines for electricity generation. These boilers are capable of producing superheated steam at temperatures up to 550 °C and extremely high pressures, which are essential for maximizing turbine efficiency and preventing blade erosion due to water droplets

Oil, Gas, and Petrochemical Industries

These industries require high-pressure, high-capacity steam for heating, separation, chemical reactions, and material transfer. Due to their ability to meet these demands and offer improved safety in hazardous environments, water tube boilers are extensively applied in refineries and petrochemical complexes.

Other Industries

Beyond power and petrochemical sectors, water tube boilers are used in industries with significant steam demand, such as textiles, chemicals, sugar mills, paper mills, leather and rubber manufacturing, packaging, and more.

Capacity of Water-Tube

Boilers

The capacity refers to the maximum amount of steam a boiler can generate within a given time (commonly measured in kg/hr or lb/hr). Package water tube boilers typically range from 5 tons/hour up to 180 tons/hour, while utility (hanging) boilers exceed 180 tons/hour. Proper capacity selection depends on consumer requirements and the cumulative steam demand of all downstream equipment.

Operating Pressure of

Water-Tube Boilers

Designed specifically for high-pressure service, watertube convert water into steam within tubes under extreme pressures while minimizing explosion risks due to reduced water volume. Package types typically operate in the 10–80 bar range (up to ~100 bar), while utility boilers can produce steam at pressures as high as 160 bar.

Steam Temperature in

WaterTube Boiler

These boilers can produce both saturated and superheated steam. Package water tube commonly deliver steam at temperatures up to 500 °C, whereas utility boilers achieve superheated steam at temperatures up to 550 °C.

Water Circulation in

Water Tube Boilers

Efficient water circulation is vital, since not all water within tubes is fully converted to steam. The purpose is to recycle un-evaporated water back into the heating cycle, ensuring higher steam production while preventing thermal stresses and tube damage.

- Natural Circulation: Driven by density differences between hot (lighter) and cold (heavier) water, effective at low pressures.

- Forced Circulation: At higher pressures, the density difference decreases, making natural circulation ineffective. In such cases, feedwater pumps force circulation to ensure adequate steam generation and tube protection.

Conclusion

Water-Tube Boiler, with their ability to deliver high-pressure steam, excellent efficiency, and superior safety, play a critical role in heavy industries and modern power plants. Their diverse design options allow customization to meet specific industrial requirements.

Although they involve higher initial investment costs, their operational benefits make them a justifiable and strategic long-term investment. The future of watertube boiler technology lies in further efficiency improvements, emissions reduction, adoption of alternative fuels (such as hydrogen, biomass, and renewable-based fuels), and expanded automation systems—all of which will continue to reinforce their importance in industrial energy supply.

No comment