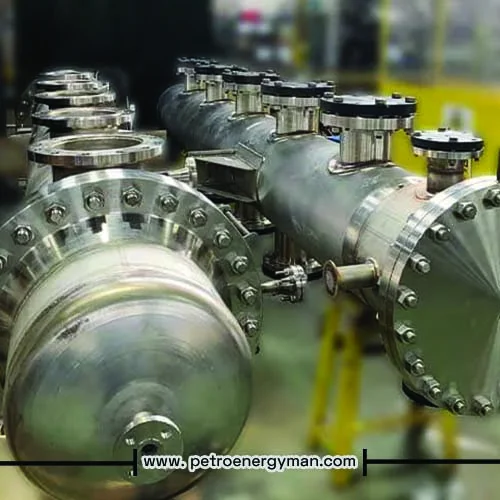

A heat exchanger is one of the most widely used industrial equipment, playing a key role in transferring heat between two fluids. In this article, we will introduce the types of heat exchangers, how they work, their advantages, and their applications in various industries. If you want a comprehensive understanding of this important and practical equipment, stay with us until the end.

What is a Heat Exchanger?

A heat exchanger is an engineered device designed to transfer heat between two or more fluids at different temperatures. These fluids can be liquids, gases, or a combination of both. The main purpose of this device is to increase or decrease the temperature of one fluid using another. This heat transfer usually occurs without direct contact between the fluids and is carried out through a conductive wall (such as the wall of a tube or plate). This feature greatly helps maintain the integrity of the fluids and prevents mixing.

For example, a car radiator transfers heat from the engine to the air, or swimming pool heat exchangers transfer boiler-heated water to pool water without direct contact. Boilers and chillers are other examples of heat exchangers commonly used in everyday life and industry.

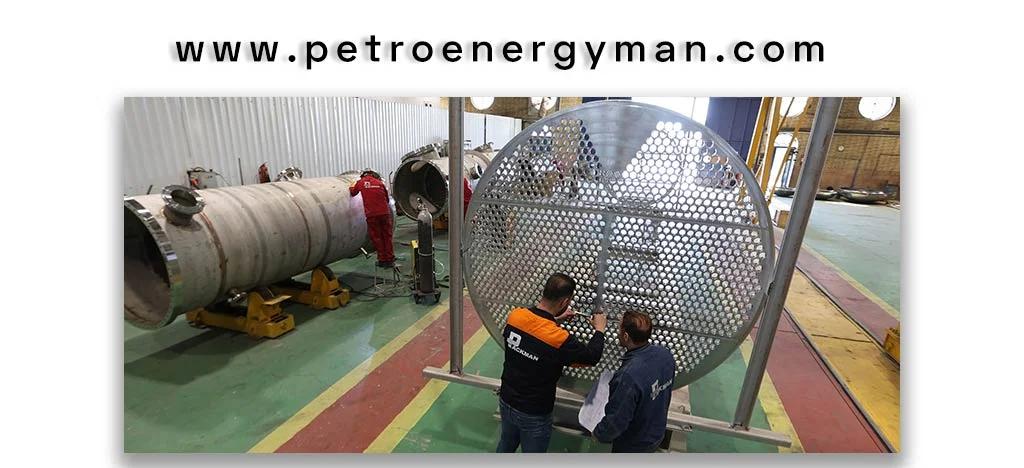

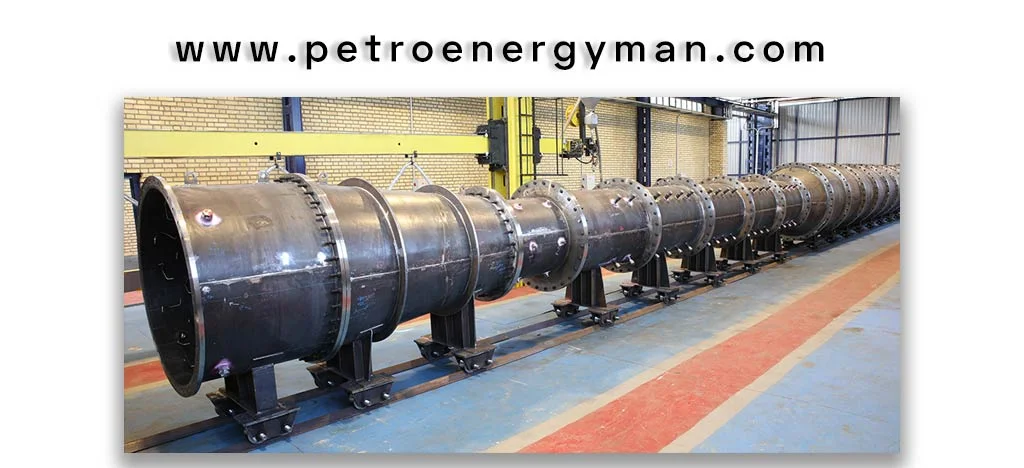

In this video, you can watch the fabrication process of a heat exchanger (tube installation) in the oil and energy industry. These devices play a vital role in heat transfer and in optimizing industrial processes.

Comparison Table of Key Parameters of Heat Exchanger

| Description | Shell-and-tube | Plate-and-frame | Spiral-plate | Printed-circuit | Air-cooled |

|---|---|---|---|---|---|

| Efficiency | Moderate | High | High | High | Moderate |

| Footprint | High but not as high as air fin cooler | Moderate | Small | Small | Large |

| Range of applicability (temperature, pressure, and transients) | High | Moderate | Low | Low | Moderate |

| Suitability to be used in fouling service | Yes | No | No | No | No |

Applications of Heat Exchangers

Heat exchangers are vital tools in various industries and have wide-ranging applications

Oil, Gas, and Petrochemical Industry

This industry is one of the most critical consumers of heat exchangers. They are used for distillation of solvents and multi-component mixtures, cooling and heating of reactors and product storage tanks, and as hydrocarbon coolers (e.g., ethylene, propylene, benzene, ethane, propane, butane). They are also applied in water circuit cooling, heat recovery (such as benzene heat recovery), as condensers and evaporators, and for heating natural gas (before or after expansion). Other applications include heating fuels to reduce viscosity, producing hot water for boilers, heating crude oil and sour gas, preheating naphtha in the ethylene process, and cooling sodium hydroxide. Without heat exchangers, core operations in petrochemical, oil, and gas plants would not be possible. Companies like PetroenergyMan

are among the leading manufacturers and suppliers of industrial heat exchangers, providing reliable solutions for these critical processes.

HVAC (Heating, Ventilation, and Air Conditioning) and Refrigeration

Heat exchangers are used in central heating and air conditioning systems in buildings (residential and commercial). Coils, a type of heat exchanger, are used in fan coil units for heating or cooling air. Over the last decade, heat exchangers have become increasingly common in chillers due to their higher efficiency. Air-cooled heat exchangers (condensers and evaporators) are also widely used in the refrigeration industry. Heating of swimming pools (domestic, chlorinated, large baths) is also achieved through heat exchangers, where boiler-heated water transfers heat to the pool water.

Power Plants

Heat exchangers are used in power plants to convert thermal energy into electricity, cool components, and recover waste heat. In nuclear power plants, they safely and efficiently separate the radioactive reactor circuit from the power generation circuit, preventing radioactive leakage into the environment. The Bushehr Nuclear Power Plant in Iran, for instance, uses shell-and-tube heat exchangers.

In solar power plants, they are necessary for transferring and isolating heat to the working fluid, enabling efficient high-pressure steam production. Wind power plants use heat exchangers to cool generators, transformers, electrical equipment, gearboxes, and bearings, ensuring efficiency and preventing damage

In steam power plants, they play a key role in producing steam for turbine rotation, cooling condensers, and heating boiler feedwater. Combined-cycle and gas power plants use them for steam generation, cooling components (such as gas turbines, generators, and air compressors), recovering waste heat from flue gases, and cooling intake air for turbines. The selection of heat exchanger type depends on factors such as application, available space, and fluid properties.

Food and Pharmaceutical Industries

In the pharmaceutical industry, heat exchangers are essential for heating, cooling, or maintaining the temperature of materials during the drug production cycle, since over 90% of processes require temperature control. Water is the primary medium used for thermal regulation. Applications include pure steam distillation, ethanol and methanol production, disinfectant solutions, pasteurization, active ingredient extraction, and distilled water production. Plate heat exchangers, due to their specific design, are widely used in this sector.

In the food industry, heat exchangers play a critical role in improving product quality and eliminating microbes. Applications include pasteurization of various food products such as milk, tomato paste, cream, juice, and cheese. Beyond pasteurization, they are also used in drying, fermentation, pre-processing, evaporation, sterilization, yeast production, cooking, crystallization, freezing, and mixing. Plate heat exchangers made of stainless steel (SS304) are extensively used in this industry.

Chemical Industry

Heat exchangers in the chemical industry are used for cooling and heating process environments, phase changes (such as converting vapor to liquid or vice versa), and controlling temperature and pressure in chemical reactions. They play a crucial role in improving efficiency and heat transfer in processes such as distillation, condensation, and chemical reactions.

Automotive Industry

In the automotive industry, heat exchangers are used in the production of various parts and for cooling electronic components such as processors and transistors. They are also applied in engine oil coolers, power steering, and battery cooling systems in advanced vehicles, as well as in radiators. Electric vehicles, due to their higher thermal management requirements, need heat exchangers with much greater efficiency compared to gasoline-powered cars

Metallurgy and Steel Industry

In metallurgy and steel

industries, heat exchangers are used for product shaping, cooling lubricants

such as oils, and controlling the temperature of various fluids. Other

important applications include cooling casting equipment, furnaces, and molds,

as well as in the production of compressors, pickling lines, hot and cold

rolling, continuous casting, and cooling galvanized steel products. Continuous

temperature regulation and cooling in these industries ensure the high quality

of output products.

Wastewater Treatment and Desalination

Heat exchangers are used for heating and cooling water in water treatment cycles and for producing fresh water from seawater. In addition, pool heat exchangers are also applied in wastewater heat recovery processes.

Marine Industry

Heat exchangers are essential equipment for marine systems, cargo ships, and commercial vessels. Their applications include oil coolers, water coolers in closed-loop systems, fuel heating systems, desalination units, and cooling of engines, generators, and other onboard equipment. Due to the corrosive marine environment, materials such as stainless steel, nickel-chrome alloys, and titanium (the most effective option) are commonly used in their construction.

Functions of Heat Exchangers

The functions of heat exchangers go beyond merely transferring heat and encompass strategic objectives in industrial processes:

Heat Transfer

The primary and fundamental purpose of heat exchangers is to transfer heat between two or more fluids to achieve or maintain the desired temperature. This process can involve heating or cooling of fluids and directly affects the quality and efficiency of the final product

Efficiency Improvement

By optimizing the heat exchange cycle, heat exchangers help increase the efficiency and thermal output of systems. This efficiency depends on factors such as surface area, construction materials, hydraulic design, and cleanliness of the exchanger. For example, in HVAC systems, heat exchangers improve device performance, reducing the energy required to achieve optimal temperature and humidity conditions.

Energy Optimization and Heat Recovery

One of the most important functions of heat exchangers is recovering heat from outgoing fluids (such as exhaust air from buildings or flue gases in power plants). This reduces the need for heating or cooling of incoming fluids, leading to significant energy savings, cost reduction, increased system efficiency, and decreased thermal load on equipment. Moreover, heat recovery contributes to reducing greenhouse gas emissions and improving energy resource management, highlighting the environmental significance of heat exchangers.

Equipment Protection and Temperature Control

Heat exchangers maintain optimal fluid and component temperatures, preventing damage to sensitive equipment (such as processors, transistors, and batteries in vehicles or turbines and generators in power plants). Precise temperature control is also critical in sensitive operations like pharmaceutical production and maintaining product quality in the food industry. This temperature management ensures operational stability and safety.

Contaminant Separation and Product Purification

In certain industrial applications, such as refineries and petrochemical complexes, heat exchangers play a vital role in distillation, purification, evaporation, condensation, mixing, and separation of materials. They assist in separating various products (e.g., gasoline, diesel) by heating crude oil before entering the distillation column and cooling the output products. Heat exchangers are also used in treatment units (like hydro-treating) and condensation processes, improving the quality and purity of final products.

The role of heat exchanger design is crucial in achieving these functions effectively.While heat transfer remains the primary function of heat exchangers, other roles—such as enhancing efficiency, optimizing energy use, and protecting equipment—demonstrate that they are not isolated components but essential elements within a larger system. They indirectly influence operational economics (cost reduction), environmental sustainability (emission reduction), and process safety (equipment protection).

This means that the value of heat exchangers lies in their ability to create positive ripple effects throughout the entire chain. Repeated emphasis on heat recovery and energy reduction, and their connection to reducing greenhouse gas emissions and dependency on fossil fuels, underscores a significant trend. Heat exchangers serve as key tools for achieving sustainability goals across various industries. This goes beyond a mere operational advantage; it is a strategic necessity in today’s era, where industries aim to reduce carbon footprints and increase resource efficiency. Consequently, the demand for higher-efficiency heat exchangers with energy recovery capabilities continues to grow.

Classification of Heat Exchangers

Heat exchangers are classified based on several key criteria, helping engineers choose and design the most suitable type for specific applications.

| Classification | Type | Description |

|---|---|---|

| Fluid Flow | Parallel Flow | Fluids move in same direction |

| Counter Flow | Fluids move in opposite directions | |

| Cross Flow | Perpendicular flow | |

| Combined Flow | Mix of above flows | |

| Construction | Recuperator | Continuous heat transfer through wall |

| Direct / Indirect | With or without direct contact | |

| Element Type | Shell & Tube | Cylindrical shell with tube bundle |

| Double Pipe | Small tube inside large tube |

Based on Fluid Flow Arrangement

- Parallel Flow (Cocurrent Flow) Exchanger: In this type, the shell-side fluid and tube-side fluid enter the heat exchanger from the same side and move in the same direction toward the opposite end.

- Counter Flow (Countercurrent Flow) Exchanger: The shell-side and tube-side fluids enter the system from opposite ends and exit from the other side. This is the most common and efficient flow mechanism in heat exchangers.

- Cross Flow Exchanger: The direction of the shell-side fluid is at a 90-degree angle to the tube-side fluid. In this system, one of the fluids may undergo a phase change.

- Hybrid/Combined Exchanger: In some cases, depending on the design and application, a combination of the above flow arrangements may be used.

Based on Construction Method

- Recuperator Exchanger: These exchangers continuously transfer heat between two fluids through a fixed wall.

- Direct and Indirect Heat Exchangers: Direct exchangers transfer heat through direct contact between fluids (e.g., wet cooling towers), whereas indirect exchangers separate the fluids with a barrier wall.

Based on Construction Elements

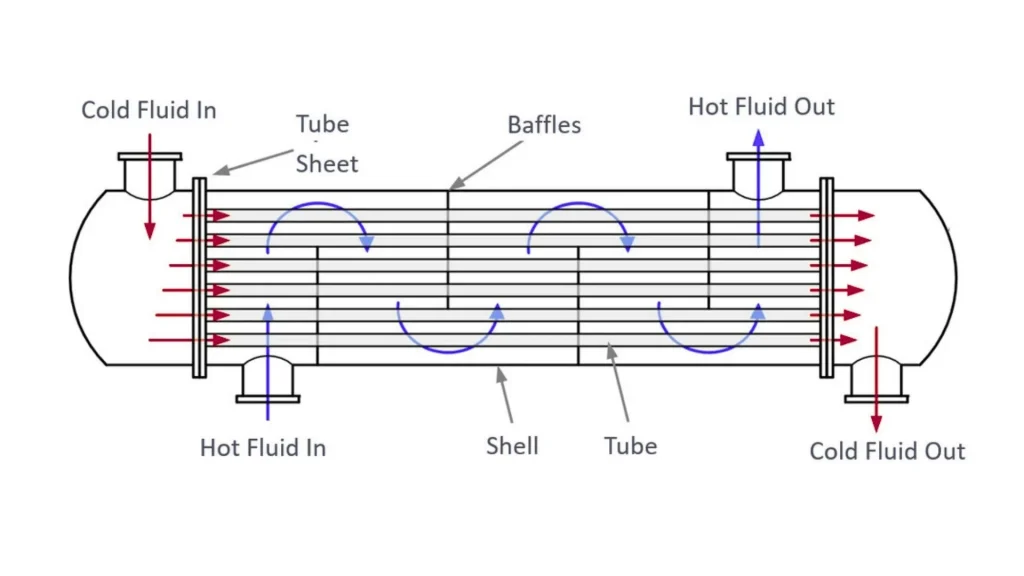

· Shell and Tube: The most common type, consisting of a cylindrical shell and a bundle of parallel tubes. One fluid flows inside the tubes while the other flows through the shell. It includes baffles to create turbulence and tube sheets to hold and seal the tubes. This type can withstand high pressures and temperatures. Subtypes include U-tube designs and TEMA standard classifications (B, C, R).

· Double Pipe (Tube-in-Tube): The simplest type, consisting of a smaller tube inside a larger one. It has a limited heat transfer area and is suitable for small capacities and high-pressure applications.

Considerations for Sizing Heat Exchangers

Determining the appropriate size and capacity of a heat exchanger is crucial for optimal and cost-effective system performance. This process is complex and depends on multiple factors:

| Factor | Description |

|---|---|

| Fluid Properties | Type, viscosity, thermal conductivity, density, specific heat; corrosion or scaling may require special design. |

| Temperature & Pressure | Inlet/outlet temps and pressures; high values may need specialized exchangers (e.g., long spiral tubes). |

| Flow Rate | Fluid speed affects heat transfer and pressure drop. |

| Phase Change | Evaporation or condensation impacts design and size. |

| Maintenance & Cleaning | Ease of inspection and cleaning, important for scaling-prone fluids. |

| Cost | Includes initial purchase, operating energy, and future expansion potential. |

| Material Compatibility | Seals and materials must resist corrosion and be compatible with fluids. |

Factors Affecting Size Selection

· Fluid Properties:

The type of fluid, viscosity, thermal conductivity, density, and heat capacity directly impact the heat exchanger’s capacity. Fluids prone to fouling require corrosion-resistant materials or specialized designs.

· Temperature and Pressure Range:

The inlet and outlet temperatures and pressures of the fluids, as well as the exchanger’s ability to withstand them, are key factors. For extremely high temperatures (e.g., 600 °C) or pressures (e.g., 350 bar), specialized designs such as long coiled tube exchangers are required.

· Flow Rate:

The fluid’s flow rate directly affects heat transfer and pressure drop; higher flow rates increase both heat transfer and pressure loss.

· Phase Change of Fluids:

Whether the fluid undergoes a phase change (e.g., evaporation or condensation) strongly influences the design and size of the heat exchanger.

· Spatial Considerations (Footprint):

Space limitations and layout constraints may affect the choice of suitable heat exchanger models.

· Maintenance and Cleaning Requirements:

Ease of cleaning and inspection, particularly for fluids prone to fouling, is an important factor in design selection.

· Overall Cost:

Includes initial purchase cost, operational energy consumption, and future system expansion possibilities.

· Material Compatibility:

Gaskets and construction materials must be compatible with the fluids used and resistant to corrosion.

Components and Functioning of Heat Exchangers

Heat exchangers, especially the shell-and-tube type which is among the most common, consist of several components, each playing a specific role in the heat transfer process. These components work together in harmony to achieve efficient thermal exchange

Components of Heat Exchangers

The shell, tubes, baffles, tube sheets, nozzles, and so on are parts of heat exchangers, each of which is explained separately.

Shell

The shell is a large cylindrical enclosure that surrounds the tubes. The shell-side fluid flows inside this chamber and comes into contact with the outer surfaces of the tubes.

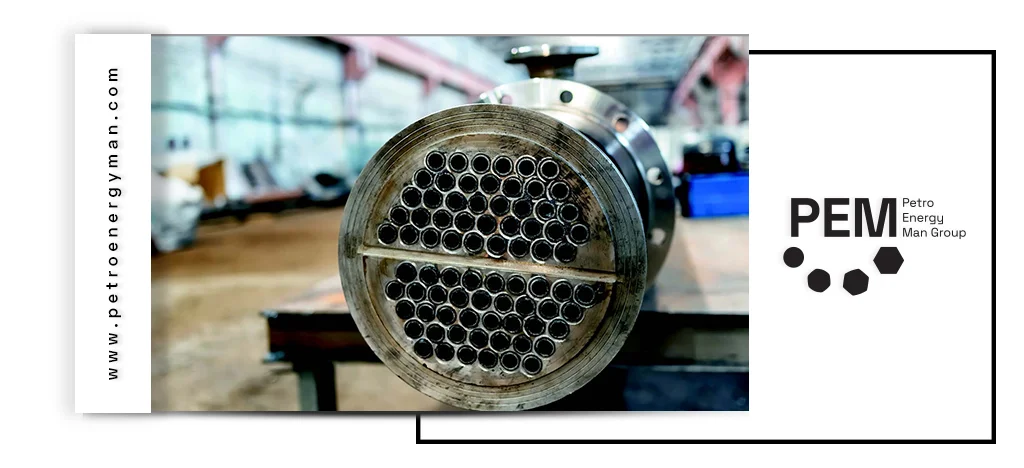

Tubes

Tubes are a set of parallel pipes placed inside the shell. They can be either straight or U-shaped, and their diameter and thickness vary depending on the application. The tube-side fluid passes through these tubes. The tube walls provide the main surface for heat transfer between the two fluids.

Baffles

Baffles are plate-like obstacles placed along the shell-side flow path. They have characteristics such as baffle cut and baffle spacing. The main functions of baffles include:

- Directing the flow of the shell-side fluid and inducing turbulent flow, which enhances the heat transfer coefficient.

- Supporting the tubes in place and preventing vibration, which could cause damage or leakage.

- Helping maintain a uniform temperature gradient, particularly in counter-flow heat exchangers.

These components together ensure that the heat exchanger operates efficiently, safely, and with maximum thermal performance.

Tube Sheet

Tube sheets are circular plates located at both ends of the shell, through which the tubes are firmly fixed. Their primary function is to hold the tubes in position and maintain proper alignment. They also provide sealing, preventing the shell-side and tube-side fluids from physically contacting or mixing. Tube sheets must be corrosion-resistant and compatible with the tube materials.

Nozzles

Nozzles serve as the inlet and outlet for the fluids entering and exiting the heat exchanger. The hot and cold fluids flow through separate nozzles and exit via dedicated outlets. The size of the nozzles can affect the pressure drop in the system.

Gaskets

In plate heat exchangers, each plate is equipped with a gasket responsible for sealing. These gaskets are made from materials resistant to high temperatures and corrosion (such as SBR, NBR, EPDM, Silicone, Viton). They form a tight, flexible seal between plates to prevent fluid mixing and maintain the integrity of the fluid pathways.

Plates

These heat exchangers consist of thin metal plates, either flat or corrugated, which create the flow channels. Hot and cold fluids flow in separate channels, and the narrow passageways create turbulence that enhances heat transfer efficiency due to the increased contact surface area.

Operation of Heat Exchangers

In a heat exchanger, the hot fluid enters one path (e.g., tubes) and the cold fluid enters another path (e.g., shell). Heat is transferred from the hotter fluid to the cooler fluid through the conductive wall separating them. This transfer occurs due to the temperature difference between the fluids and the thermal conductivity of the wall material. After the heat exchange, the fluids exit through separate outlets at changed temperatures.

The description of each component highlights that heat exchanger performance results from the complex synergy among parts. Baffles not only increase turbulence but also support the tubes, directly influencing efficiency and durability. Tube sheets hold the tubes and provide sealing. This interdependence means that the design and optimization of each component must consider its impact on the entire system, not just in isolation.

Reference to factors such as the difficulty of cleaning smaller tubes or the differences in maintenance between gasketed and brazed plate heat exchangers highlights that maintainability and ease of operation after installation are crucial considerations in heat exchanger design. Engineers do not focus solely on maximizing thermal efficiency; they also consider lifecycle costs, including installation, operation, maintenance, and repair. This comprehensive approach emphasizes the importance of designing for durability and serviceability alongside primary performance

Conclusion

The heat exchanger is a key, multifunctional piece of equipment that plays a central role in numerous industrial processes. From oil and gas refineries to power plants, food and pharmaceutical industries, and the automotive sector, these devices are essential for heat transfer, efficiency improvement, energy optimization, and equipment protection. Their ability to transfer heat between fluids without direct contact makes them indispensable for maintaining process integrity and product quality.

No comment