Water Tube Boiler Mountings are essential for the safe and efficient operation of steam boilers. In this article, we cover key Boiler mountings including steam stop valves, safety valves, feed water regulators, pressure gauges, blowdown valves, level indicators, air release valves, and TDS sensors.You will learn how each component helps control water and steam levels, protect the boiler from overpressure or contamination, and ensure smooth operation.

Water Tube Boiler Mountings

Explore the essential mountings that keep water tube boilers safe and efficient: Main Steam Stop Valve, Auxiliary Steam Stop Valve, Boiler Safety Valve, Steam Drum Level Gauge Glass, Air Release Valve, Feed Check and Control Valve, Pressure Gauge Connection, Boiler Blowdown Valve, Scum Blowdown Valve, Sampling Connection, Low-Level Alarm, Soot Blowers, Automatic Feed Water Regulator, Manhole, and TDS Sensor and Probe.Learn more about the role of each mounting in maintaining boiler performance and safety.

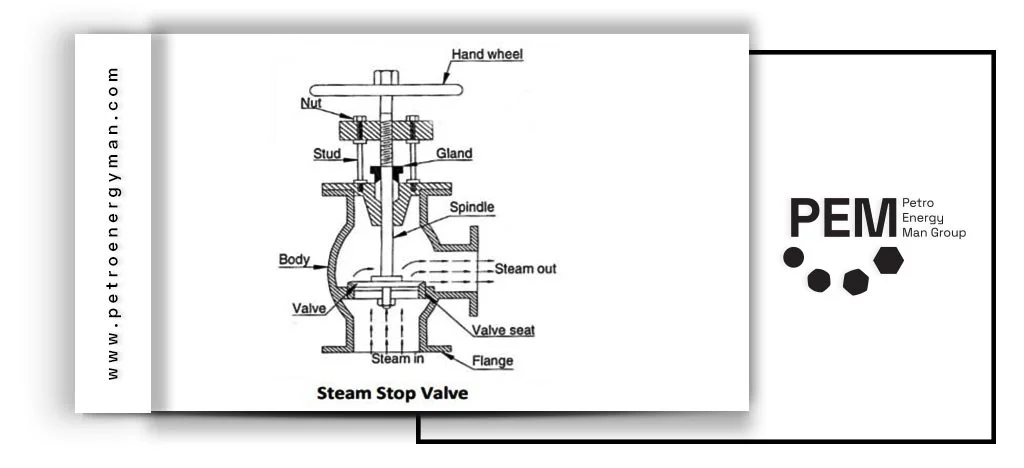

Main Steam Stop Valve

Water Tube Boiler Mountings include the main steam stop valve, which is installed between the main steam line and the distribution header. Its primary function is to allow or stop the flow of steam from the boiler to the steam pipeline, or from the steam line to the consumption process. When open, it directs the generated steam into the main steam line, and when closed, it completely isolates the boiler from the steam system. This valve is typically mounted close to the boiler and must always be operated either fully open or fully closed, never partly open for throttling. In multi-boiler installations, an additional isolating valve must be installed in series with the main valve, and at least one of these valves should be lockable in the closed position. Main steam stop valves are usually globe-type valves with an angular flow path.

Auxiliary Steam Stop Valve

The auxiliary steam stop valve controls the flow of steam to auxiliary steam lines. It is essentially a smaller version of the main steam stop valve and is designed to isolate the boiler from secondary systems. This valve is often manufactured as a check valve to prevent backflow of steam into the boiler in case of malfunction or system failure. It is normally installed directly on the boiler outlet and plays an important role in the safe and reliable operation of auxiliary steam lines.

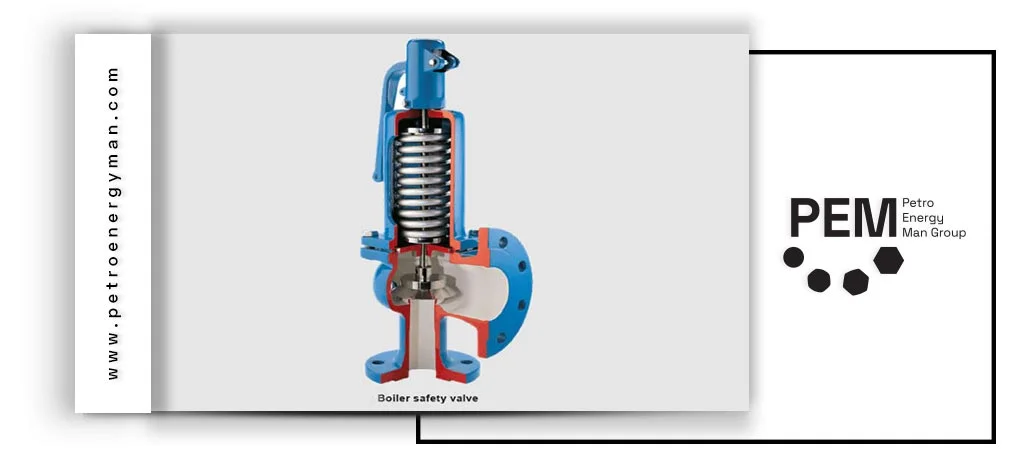

Boiler Safety Valve

Water Tube Boiler Accessories include the boiler safety valve, which is one of the essential components designed to protect the boiler from excessive pressure and prevent potential damage. The primary function of this valve is to automatically release steam whenever the generated steam pressure rises above the allowable limit.

Safety valves are typically installed in pairs: a main valve and a backup valve that is set to open at a slightly higher pressure. This ensures the boiler remains protected even if the main valve fails. The opening pressure of these valves is adjusted and sealed in the presence of an authorized inspector so that no one can tamper with the settings. Safety valves play a vital role in preventing dangerous pressure buildup in steam systems.

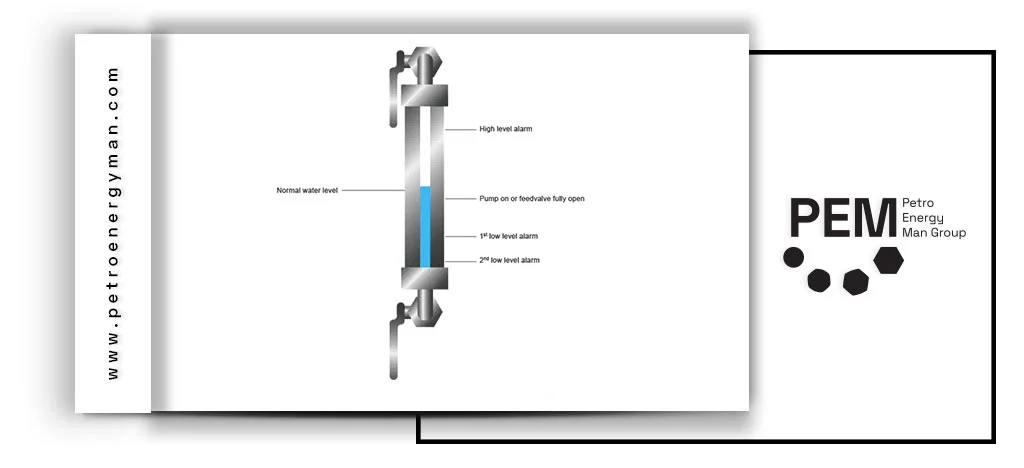

Boiler Steam Drum Level Gauge Glass

The steam drum level gauge glass, also known as the water level indicator, is usually installed in pairs to allow manual monitoring of the water level inside the boiler steam drum. These gauge glasses visually display the water level and protect the boiler from potential damage, as low water levels and excessive temperatures can cause severe failures.

The design and construction of gauge glasses are based on the boiler’s working pressure. They are installed such that their lowest visible point is at least 50 mm above the critical water level to prevent overheating. These glasses must be inspected and tested daily to ensure proper operation and to maintain personnel safety against possible hazards.

Air Release Valve or Boiler Vent

Water Tube Boiler Mountings include the air release valve, which is typically installed on headers and drums to protect the system from damage. This valve prevents sudden vacuum formation in the boiler during pressure drops or rapid steam pressure increases and allows air to escape when filling the steam drum or during steam generation. It can also return excess air into the boiler during venting.

Air release valves are usually installed at the highest points of the system, where air tends to accumulate. They are responsible for removing non-condensable gases such as air, which have no thermal value and can impair the performance of the steam plant by covering heat transfer surfaces or causing corrosion in the condensate system.

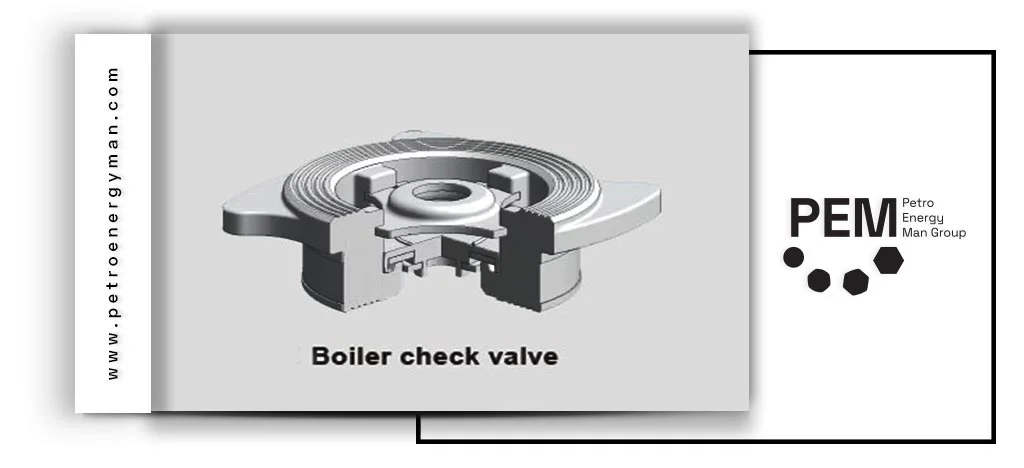

Feed Check and Control Valve

The feed check valve is designed to control the flow of water from the feed pump to the boiler and prevent backflow from the boiler to the pump. This valve ensures one-way flow and is often installed in pairs: a main valve and an auxiliary valve. The main valve is installed in an accessible position to facilitate operation.

These valves often feature a visual indicator showing whether they are open or closed. Using two feed check valves provides double isolation for the feed line, enhancing operational safety and reliability.

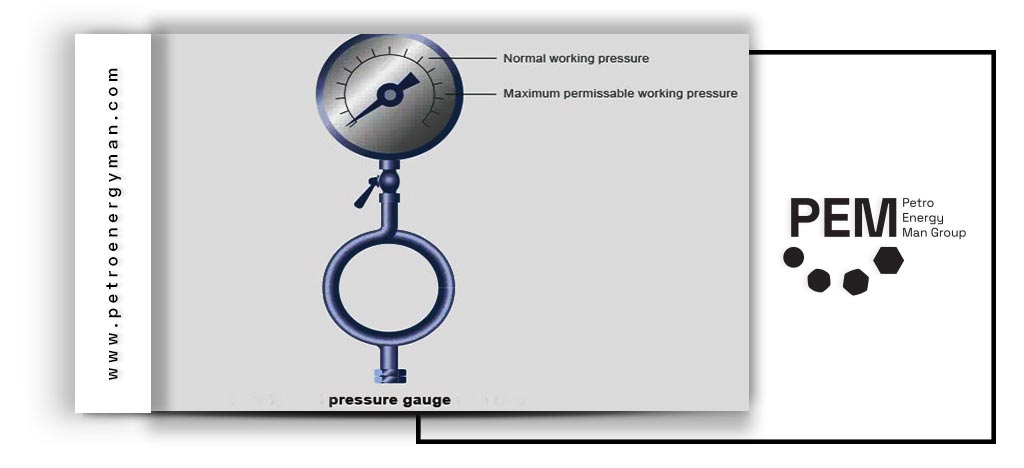

Pressure Gauge Connection

Boiler mountings include a pressure gauge, which every steam generator should be equipped with, typically a simple gauge conforming to EN 12953 standards. Pressure gauges continuously display the pressure inside the boiler and can be connected to the steam space, water column, or steam connection of the boiler. To protect the gauge mechanism from high temperatures, a siphon or equivalent device is often used.

The display should have a minimum diameter of 150 mm and indicate both the normal operating pressure and the maximum allowable working pressure.

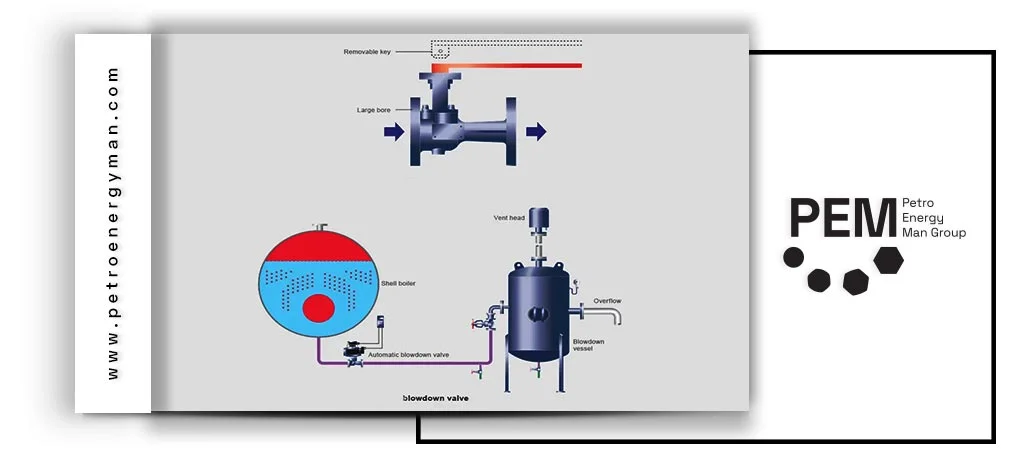

Boiler Blowdown Valve

Boiler mountings also include the boiler blowdown valve, which is used to remove sludge, sediment, and other impurities from the bottom of the water drum. This process, known as blowdown, is essential for maintaining boiler water parameters within acceptable limits, minimizing issues such as scaling, corrosion, and the transport of solid particles.

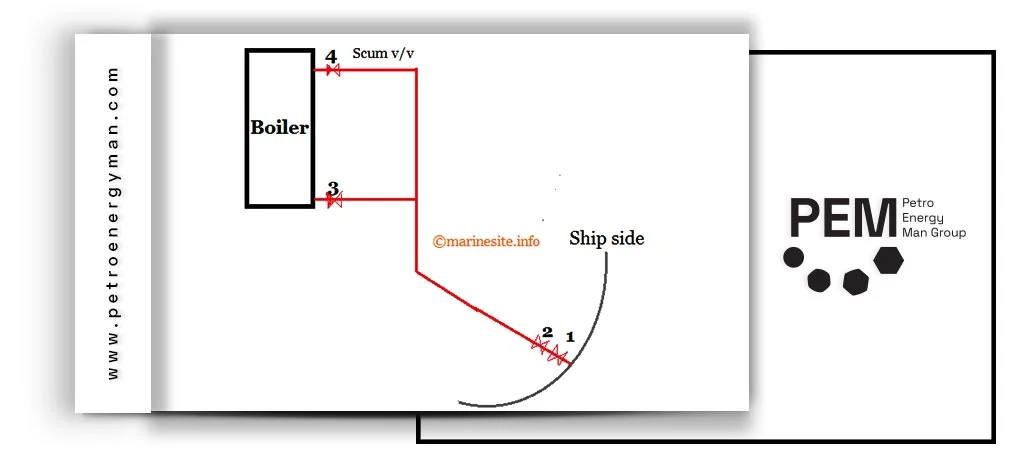

Scum Blowdown Valve

Water Tube Boiler Mountings include the scum blowdown valve, which is designed to remove floating impurities, surface oils, and other scum formed on the water surface. This valve usually features a shallow chamber installed at the water surface, allowing the collection and discharge of floating materials. The scum blowdown valve helps clean the water surface from oily layers or foam caused by agitation or contamination, playing an important role in improving boiler water quality and enhancing system efficiency.

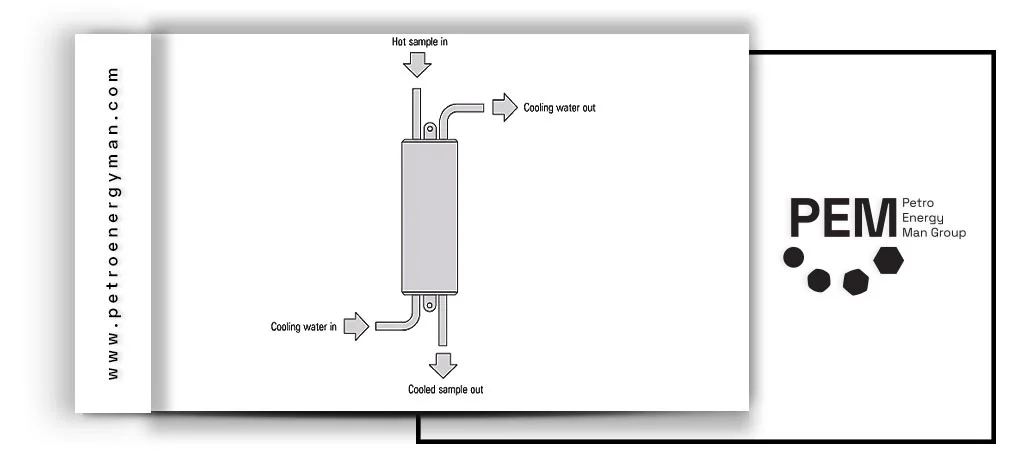

Sampling Connection

The boiler sampling connection typically consists of a control valve and a cooler, allowing the collection of feedwater samples for analysis at any time. The sample cooler is used to increase safety, prevent burns, and maintain the accuracy of test results. These devices prevent sudden evaporation and loss of volatile substances.

To ensure accurate testing and compliance with sampling standards, it is recommended to use stainless steel piping and carefully control the sample’s temperature and flow rate. These practices ensure that the collected samples accurately represent the boiler feedwater quality and provide reliable chemical analysis results.

Low-Level Alarm

Water Tube Boiler Accessories include the low-level alarm, a device that activates an audible warning when the water level in the steam drum drops below a set threshold. This alarm is a critical safety feature for the boiler, preventing continued fuel combustion when the water level is too low. Many systems also include an extremely low-level alarm that can shut down the burner to prevent overheating.

Soot Blowers

Soot blowers are designed to remove soot and combustion residues from boiler tube surfaces, typically using steam or compressed air. Regular cleaning of ash deposits from heat transfer surfaces is essential for maintaining boiler thermal efficiency and controlling flue gas temperatures within the design range.

Soot blowers can be designed as fully retractable, semi-retractable, or wall-mounted on the boiler, allowing cleaning operations without a full boiler shutdown and extending the service life of thermal equipment.

Automatic Feed Water Regulator

Boiler mountings include the automatic feed water regulator, a device that automatically adjusts the incoming water flow to the steam drum to maintain a constant and safe water level, even when the boiler load fluctuates. This device is usually installed on the feed line, before the main feed check valve, and automatically controls the water flow to ensure the desired water level is maintained in the steam drum.

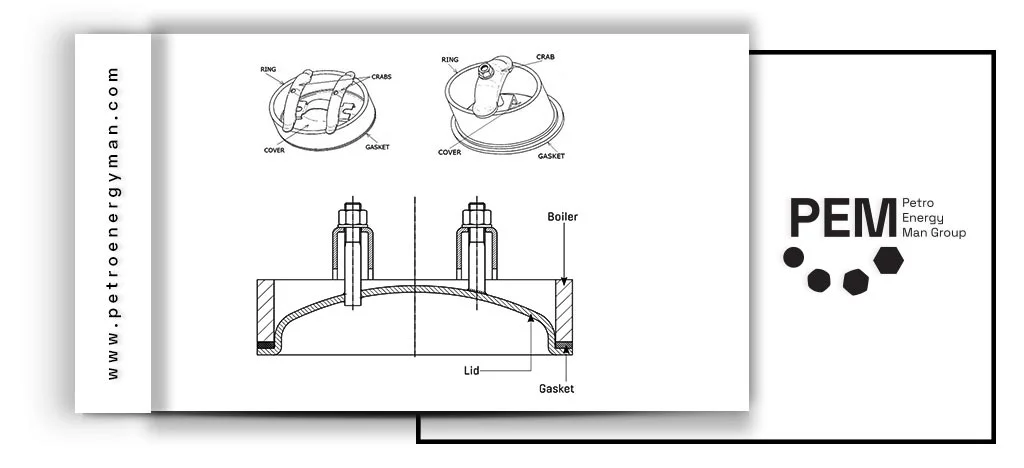

Manhole

Manholes are large openings in the water drum and steam drum that allow personnel to enter for inspection, maintenance, or internal cleaning of the boiler. In water tube boilers, these manholes are provided on all drums to ensure safe access to the interior for maintenance and inspection operations.

Manholes are typically designed in an oval shape, making it easier to install and remove the cover with less stress on the drum. This design ensures safe entry and exit for personnel while preserving the structural integrity of the boiler during opening and closing operations.

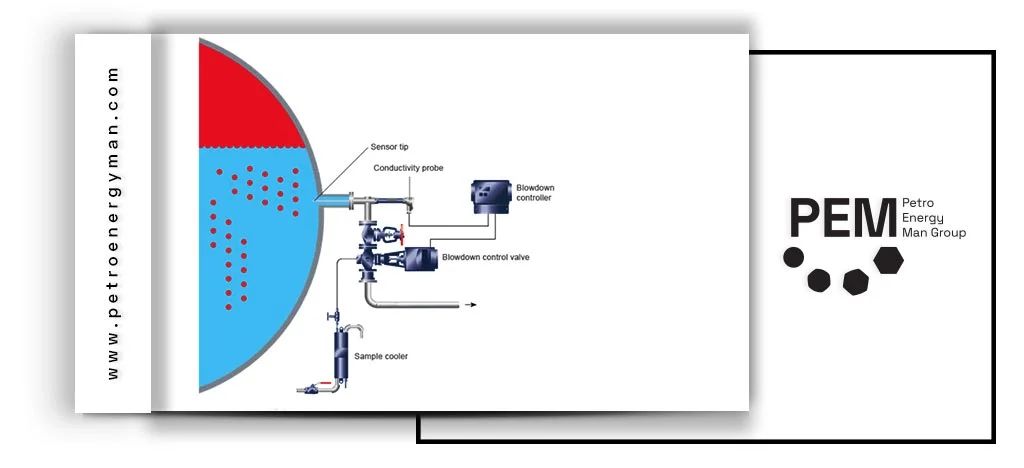

TDS Sensor and Probe

Water Tube Boiler Mountings include TDS (Total Dissolved Solids) sensors and probes, which are used for continuous monitoring of the dissolved solids concentration in boiler water. These devices measure the electrical conductivity of the boiler water to indicate the TDS level, enabling continuous water quality control.

If the TDS level exceeds the permissible limit, audible and visual alarms are activated, and by performing manual blowdown and adding fresh feedwater, the dissolved solids concentration is reduced, optimizing boiler water conditions.

To ensure accuracy and proper performance, regular inspection of TDS probes for physical damage, scaling, and clogging is essential. These inspections guarantee that the sensors consistently provide precise and reliable information about the boiler water quality.

Conclusion

This text provides a comprehensive overview of essential Water Tube Boiler Mountings, each playing a vital role in maintaining the stability and performance of the steam system. These components include main and auxiliary steam stop valves, safety valves, automatic feed water regulators, pressure gauges, steam drum level gauge glasses, blowdown and scum blowdown valves, air release valves, soot blowers, manholes, and TDS sensors.

All of these devices are designed to ensure safety, optimize efficiency, control water and steam levels, and enhance system reliability, playing a key role in the continuous and safe operation of industrial boilers.

No comment