The shell and tube heat exchanger is one of the essential pieces of equipment in many large industries, used for heat transfer between two fluids. This type of exchanger has widespread applications in chemical industries, including crude oil distillation units. This comprehensive text provides an in-depth examination of these types of exchangers, offering complete information about their operation, components, types, applications, and testing methods. Join us to learn about the operation of these vital devices, their key components such as the shell, tubes, and baffles, as well as their diverse designs based on industrial standards and specific needs. This content serves as a comprehensive guide to better understand this complex technology and its broad applications across various industries.

What is a Shell and Tube Heat Exchanger?

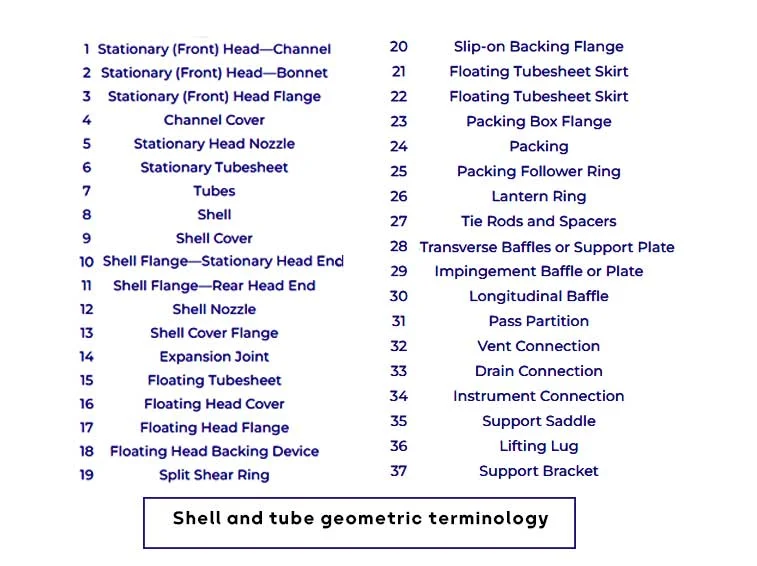

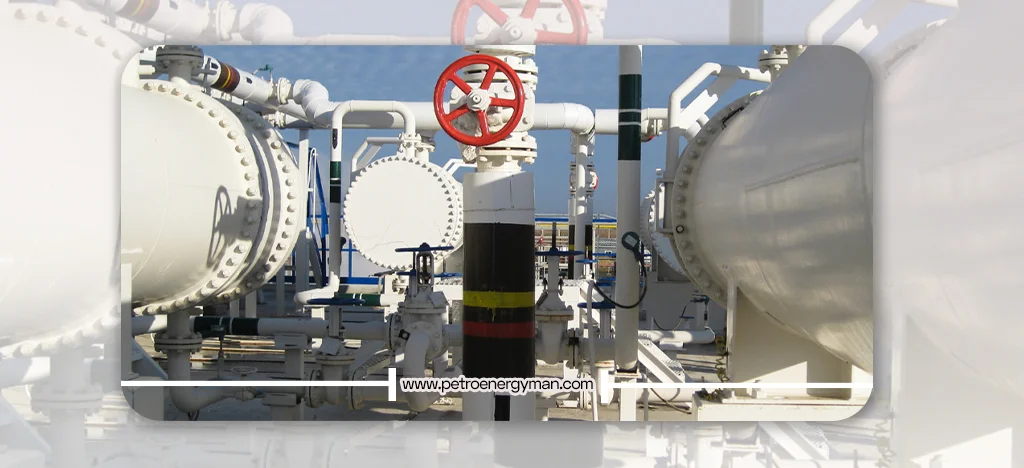

A Shell-and-Tube heat exchanger is a device used to transfer heat between two different fluids, usually liquids or gases. This exchanger is one of the most common and widely used types of heat exchangers in various industries. Its name comes from its basic structure, which consists of a large cylindrical vessel called the shell and a number of tubes inside it. This equipment is extensively used in many critical industries such as oil refineries, petrochemical plants, power plants, chemical industries, and other manufacturing processes.

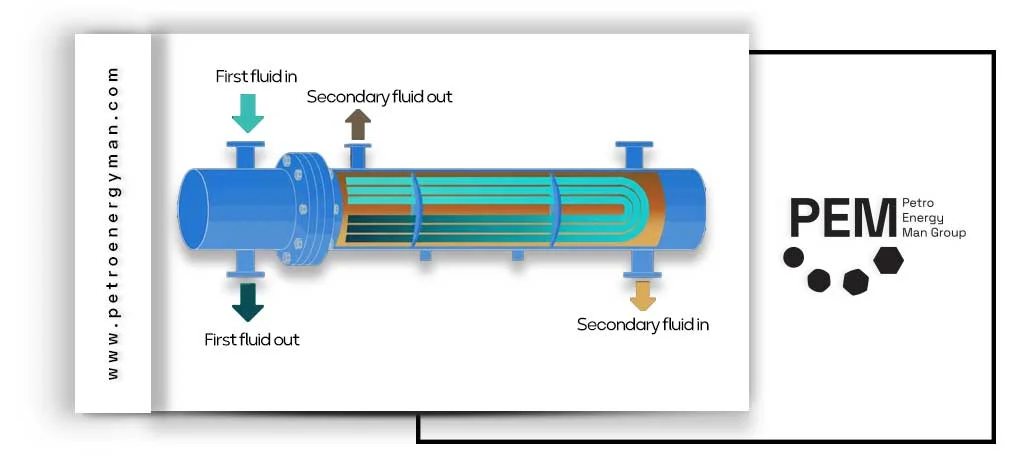

The general heat transfer mechanism in these exchangers is such that two fluids exchange heat with each other without direct mass contact. The fluid requiring heating or cooling flows through the tubes, while the other fluid flows outside the tubes, within the shell. This heat exchange occurs through the metallic tube walls, causing one fluid to heat up and the other to cool down. Ideally, without considering energy loss, the amount of heat lost by the hot fluid equals the amount of heat gained by the cold fluid.

The Shell-and-Tube heat exchanger is one of the most common types of heat exchangers, typically used in oil refineries and large process plants. This type of exchanger consists of a pressure vessel (shell) and a set of closely packed parallel tubes (tube bundle).

Operating Principles of Shell and Tube Heat Exchangers

Tube-and-Shell Heat Exchanger operate based on the concept of flow and thermal contact between two fluids. They transfer heat indirectly between a hot fluid and a cold fluid without the fluids mixing.

How Do Shell and Tube Heat Exchangers Work?

The tube and shell heat exchanger is one of the most widely used industrial pieces of equipment for heat transfer between two immiscible fluids. This exchanger consists of two main parts: the Shell, which is a cylindrical chamber, and the Tube Bundle, which is placed inside this shell. In this system, one fluid flows through the tubes, and the other fluid flows through the space between the tubes and the shell wall. The main objective is to transfer heat from one fluid to the other without them mixing. In other words, heat exchange occurs indirectly.

Fluid Flow Path: One fluid (e.g., the hot fluid) enters the tubes through the inlet nozzle and, after passing through the length of the tubes, exits from the other end. The second fluid (e.g., the cold fluid) enters the shell through another inlet nozzle and flows around the tubes. In this case, the heat from the hot fluid is transferred through the tube walls to the cold fluid without the two fluids mixing.

Flow Arrangement Design: In shell and tube heat exchangers, the movement of fluids can be designed in various configurations:

- Parallel Flow: Both fluids enter from the same side and exit to the same side.

- Counter Flow: Fluids enter from opposite ends and move towards each other. This arrangement usually has higher thermal efficiency.

- Cross Flow: The flow path of one fluid is perpendicular to the flow path of the other fluid.

Design of Shell and Tube Heat Exchangers

The design of Tube-and-Shell Heat Exchanger is one of the specialized processes in mechanical engineering and process industries. The primary goal in this process is to achieve the highest heat transfer rate with the lowest pressure drop and construction/operating costs. This design requires precise selection of geometric structure, suitable raw materials, and the use of advanced software for analyzing and optimizing exchanger performance.

Stages of Shell And Tube Heat Exchanger Design

Tube-and-Shell Heat Exchanger design is a complex process requiring significant knowledge and experience, and various factors must be considered. The general design stages are as follows:

Determining Requirements and Operating Conditions

The first step in heat exchanger design is defining the user’s needs and project specifications. These needs include the type of fluids used, required thermal capacity, fluid temperature difference (inlet/outlet), operating pressure, and cost considerations. The physical and chemical properties of the fluids, such as density, viscosity, and heat capacity, must also be specified at this stage.

Selecting the Exchanger Type

After determining the requirements, the appropriate type of heat exchanger is selected. Heat exchangers come in various types, including shell and tube, plate heat exchangers, double-pipe heat exchangers, and spiral heat exchangers. Shell and tube heat exchangers are one of the most common types. The selection of the exchanger type and baffle configuration is based on operating conditions and project needs.

Calculating Size and Heat Transfer Surface Area

After selecting the exchanger type, the size of the heat exchanger is calculated. This calculation is based on the required heat transfer rate and the overall heat transfer coefficient. The size of the heat exchanger depends on thermal capacity, fluid temperature difference, and heat transfer coefficient. The heat transfer coefficient is influenced by factors such as tube thickness, material properties, and fluid flow conditions.

Material Selection

The material of the shell and tubes must be selected according to operating temperature, pressure, and fluid properties to be resistant to corrosion and erosion. The type of fluids used in the heat exchanger impacts its design.

Mechanical Design

The mechanical design of the heat exchanger is performed after calculating its size. Mechanical design includes determining the exchanger dimensions, tube type, number of tubes, and type of tube sheets and gaskets. This design must comply with standards and safety requirements.

Fluid Flow and Pressure Drop Analysis

Important points regarding the placement of hot and cold fluids and pressure drop must be considered in Tube-and-Shell Heat Exchanger design. The pressure drop in the exchanger must be within the allowable range to ensure system efficiency. Baffles play a crucial role in flow distribution and pressure drop reduction

Using Design Software

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Specialized software plays a significant role in designing and simulating shell and tube heat exchangers. This software helps engineers perform precise and optimized designs. Several powerful software packages exist for Tube-and-Shell Heat Exchanger design, detailed below:

- HTRI Xchanger Suite: One of the most powerful tools for designing and simulating heat exchangers. Developed by Heat Transfer Research, Inc. (HTRI), it provides a wide range of software solutions for heat transfer equipment.

- Capabilities: HTRI Xchanger Suite includes various modules, each used for designing, simulating, and rating specific types of heat exchangers.

- Xist: The main module forTube-and-Shell Heat Exchanger . It allows precise evaluation of thermal performance and pressure drop.

- Xace: Used for designing and rating air coolers and economizers.

- Xphe: Used for plate heat exchangers.

- Xfh: An advanced tool for detailed analysis of fired heaters.

- Xvib: Used for analyzing tube vibrations.

Applications: This software helps operating companies, engineering contractors, exchanger manufacturers, and related industries design, simulate, and optimize heat exchangers with high accuracy.

Measurement of Shell-and-Tube Heat Exchangers

Measuring this type of heat exchanger is a fundamental step in the design and performance evaluation of such systems.

Measurement and Evaluation Methods

The measurement and evaluation of shell-and-tube heat exchangers involve several analytical and experimental methods aimed at optimizing performance and efficiency.

Calculation of Heat Transfer Surface Area

Calculating the tube surface area in a shell-and-tube heat exchanger is essential for designing an efficient system. This area directly affects the heat transfer capacity of the exchanger. The determination of the heat transfer surface area should be based on the required heat duty and the desired capacity of the exchanger.

Thermal and Hydrodynamic Analysis

Extensive experimental and numerical studies have been conducted to investigate the thermal and hydrodynamic performance of shell-and-tube heat exchangers.

- Analytical and Experimental Methods: The heat transfer rate along the tube can be calculated using analytical and experimental techniques. For example, the tube-side heat transfer coefficient in a helical coil has been measured using the Wilson plot method. In addition, numerical studies have been carried out on the freezing and melting behavior of phase change materials in triple-tube heat exchangers using fins and nanoparticles.

- Modeling and Simulation: Thermal modeling of shell-and-tube heat exchangers is performed using the e-NTU method, and optimization is conducted with multi-objective genetic algorithms to enhance efficiency and reduce overall annual costs.

- Effect of Nanofluids: The use of nanofluids such as water–aluminum oxide and multi-walled carbon nanotube–water can significantly improve heat transfer rates. For instance, a water/alumina nanofluid can increase the heat transfer rate by up to 9%, while multi-walled carbon nanotubes in water can enhance the heat transfer coefficient by up to 75%.

Design and Selection Considerations

The selection and sizing of a heat exchanger require an understanding of the types of exchangers, available options, and the application environment. The main criteria for measurement and selection include:

- Exchanger performance: The function of the exchanger (e.g., condensation or boiling).

- Pressure and temperature limitations: Operating pressure (high/low) and the temperature range that may vary during the process.

- Fluid flow capacity: The exchanger’s ability to handle a certain volume of fluid.

- Required materials: Conditions such as sudden temperature changes or corrosive environments may require specific materials.

- Thermal fluid properties: If the fluid is prone to fouling, corrosion-resistant materials may be necessary.

- Space and layout constraints: Physical space limitations and system arrangement can influence the choice of exchanger model.

- Maintenance requirements: Ease of cleaning, repair, and inspection can also be an important factor.

Measurement Tools

Various instruments are used to measure and monitor the performance of heat exchangers, including:

- Temperature sensors: To monitor temperatures at different points in the exchanger.

- Rotameters: For measuring and adjusting the flow rate of hot and cold fluids.

- Control panels and monitoring systems: Including displays and other instrumentation devices for controlling and supervising performance.

- Safety equipment: Appropriate safety tools, such as goggles and gloves, are essential when working with heat exchangers.

These tools, together with thermodynamic calculations and fluid mechanics analysis, contribute to optimal selection and accurate measurement of shell-and-tube heat exchangers.

Price of Shell and Tube Heat Exchangers

The price of shell and tube heat exchangers depends on several factors, including:

- Material of Construction: The type of material used for the shell, tubes, tube sheets, and baffles (e.g., carbon steel, stainless steel, copper, titanium, special alloys) directly affects the price. Materials resistant to corrosion or high temperatures are more expensive.

- Size and Capacity: Larger exchangers with higher heat transfer capacity have higher costs.

- Operating Pressure and Temperature: Design for high pressures or very high temperatures requires thicker materials and more complex manufacturing processes, increasing the price.

- Type and Configuration: Specific types like U-tube exchangers, floating head types, or special baffle designs can impact the final price.

- Standards and Certifications: Compliance with international standards like TEMA (Tubular Exchanger Manufacturers Association) or ASME (American Society of Mechanical Engineers) and the need for specific certifications can add to the cost.

- Ancillary Equipment: The presence of equipment like valves, instrumentation, insulation, and supports also affects the final price.

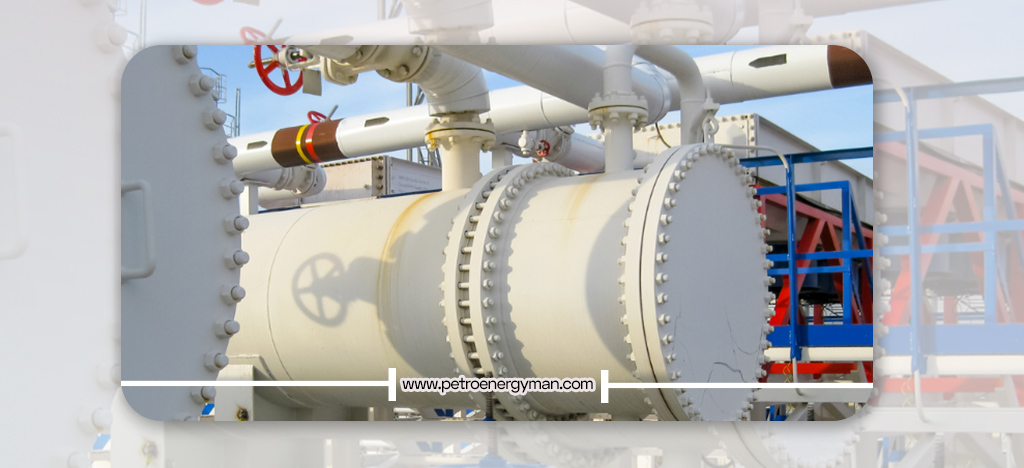

Geometric Terms in Shell and Tube Exchangers

Components of Shell And Tube Heat Exchanger

Tube-and-Shell Heat Exchangers consist of numerous components, each playing a vital role in the system’s performance and integrity. Understanding these components and their materials is essential for optimal design, construction, and maintenance.

Shell

This is the large pressure vessel that houses the tube bundle. Its function is to direct the flow of the fluid outside the tubes and ensure efficient heat transfer.

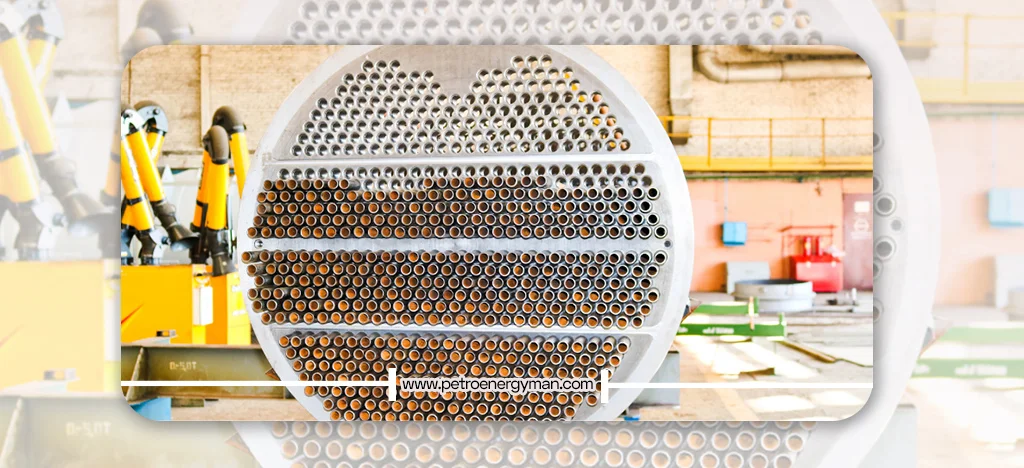

Tubes

Tubes are the primary heat transfer elements through which the primary fluid flows. They are typically made of high-quality stainless steel or copper, known for excellent thermal conductivity and durability. Seamless tubes are produced via extrusion, while welded tubes are made by rolling a strip into a cylinder and welding the seam; welded tubes are usually more cost-effective. Common tube diameters are 5/8, 3/4, and 1 inch. Tubes with smaller diameters are more difficult to clean mechanically, while larger tubes are used to facilitate cleaning or reduce pressure drop. Tube wall thickness typically ranges between 12 to 16 BWG (0.109 to 0.065 inches). Thinner-walled tubes (18 to 20 BWG) are used when expensive materials like titanium are employed.

Tube Sheets

These are thick metal plates with precisely drilled holes for securing the tubes. Tube sheets are critical for maintaining the structural integrity of the heat exchanger and preventing fluid mixing. They must resist corrosive attack from both fluids and be electrochemically compatible with the tube and tube-side materials. The “tube pitch” is the distance between tube hole centers, typically 1.25 times the outer tube diameter. Triangular pitch is used for higher heat transfer and compactness, while square pitch is used for easier mechanical cleaning. Forged tube sheets are produced using compressive forces, resulting in higher strength and durability compared to casting or machining methods, making them ideal for high-stress applications.

Baffles

Baffles are metal plates strategically placed inside the shell to direct the fluid flow across the tubes. They improve heat transfer efficiency by increasing fluid velocity and ensuring multiple passes over the tubes.

Tie Rods and Tie Rod Nuts

Tie rods hold the baffles in place and maintain their spacing within the shell. Nuts secure these rods, ensuring the stability and alignment of the entire assembly.

Spacer Tubes

These tubes maintain the proper distance between baffles and ensure uniform tube spacing within the bundle. They prevent tube contact, which could cause damage and reduce efficiency.

Body Flanges and ANSI Flanges

These parts connect different sections of the heat exchanger, enabling easy assembly, disassembly, and maintenance. Designed for tight sealing and strong connections.

Studs and Nuts

Used to fasten flanges and ensure a strong seal, preventing leaks.

Applications of Shell and Tube Heat Exchangers in Industries

The high adaptability and reliability of shell and tube heat exchangers make them an integral part of a wide range of industries. Their widespread use across various sectors, from heavy and processing industries to sensitive areas like food and pharmaceuticals, demonstrates their robustness and unparalleled ability to adapt to different fluids, temperatures, and pressures. These features make them a fundamental technology, not just a specific solution, but a vital component in industrial infrastructure.

Oil, Gas, and Petrochemical Industries: These exchangers are used for heating or cooling chemicals, oils, and gases in processes like distillation, condensation, and chemical reactions. In refineries, they are used for crude oil distillation, preheating and cooling fluids, maintaining optimal temperatures in catalytic reactions, condensing vapors, and cooling towers. Due to their durability and high resistance to harsh temperature and pressure conditions, they are highly suitable for the demanding environments of this industry. They are also used in heat recovery processes during oil-water-gas separation.

Power Generation: In power plants, shell and tube heat exchangers serve as condensers, converting steam water into liquid water for return to boilers. They are critical for maintaining the temperature of turbine and generator cooling water systems, preventing overheating, and ensuring uninterrupted power generation. They are also used for feedwater preheating, gearbox oil cooling, and heat recovery from exhaust gases to increase overall efficiency.

Food and Beverage Industries: Used for pasteurizing, sterilizing, and cooling liquids like juices, dairy products, and sauces. Maintaining precise temperatures is vital for product quality and safety. Stainless steel is a common material choice due to its corrosion resistance and ease of cleaning.

Pharmaceutical Industry: Tube-and-Shell Heat Exchangers are used for precise temperature control in processes such as crystallization, distillation, and sterilization of pharmaceutical materials.

Shell and Tube Heat Exchanger Pressure Testing Methods

Pressure testing is critical for confirming the safety and integrity of pressure vessels. The primary goal is to detect any leaks or weaknesses in the coils and connections. Failure to comply with protocols can lead to equipment damage or catastrophic failures.

Hydrostatic Testing

Hydrostatic testing is one

of the most common and safest methods for pressure testing shell and tube heat

exchangers. In this process, the equipment is filled with clean water and

subjected to pressure exceeding the maximum allowable operating pressure to

ensure there are no leaks, structural defects, or mechanical weaknesses. The

applied pressure is typically between 1.3 to 1.5 times the design pressure, but

according to ASME requirements, it may be up to 4 times the design pressure in

some conditions.

This test is performed in several main stages: First, the

exchanger is completely isolated, and all valves are closed. Then, vents are

installed to remove trapped air bubbles, and the system is completely filled

with water. Next, the water pressure is gradually increased to the specified

limit. This pressure is maintained for a specified duration to allow sufficient

time for inspection. During pressure application, the operator visually

inspects all welds, connections, and flanges to ensure there are no leaks or

defects.

After completing the test, the pressure is slowly reduced, and the

water is drained. The exchanger is then thoroughly dried to prevent internal

corrosion. Important considerations for this test include maintaining suitable

water and equipment temperatures. The water temperature should be at least 60°F

(15°C), and the metal temperature should not be below the minimum design

temperature to prevent thermal cracking. Compared to gas methods, hydrostatic

testing is safer because the stored energy in liquids is significantly less

than in gases, thus greatly reducing potential hazards in case of leaks or

failures.

Pneumatic Testing

Pneumatic testing is a common method for assessing the strength and sealing of heat exchangers and other pressure equipment, especially when water cannot be used or is undesirable due to reasons like preventing moisture ingress or difficulty in complete drainage. In this method, compressed gases such as air, nitrogen, or other inert gases are used instead of water. In the pneumatic testing process, gas is introduced into the system in a controlled and gradual manner to increase the pressure uniformly.

The test pressure is usually set at 1.1 times the maximum working pressure. If there is a leak, the sound of escaping gas or visible signs are usually quickly detectable. However, unlike hydrostatic testing, pneumatic testing carries a higher risk because compressed gases store significant energy and can cause serious damage or even life-threatening hazards in case of sudden rupture or leakage. Therefore, strict adherence to safety precautions is essential.

The test must be performed in a controlled environment following stringent safety protocols. To reduce risk, operators often use cameras or remote monitoring equipment to observe the test status without physical proximity. Also, the number of people present on-site should be minimized. Overall, pneumatic testing is an effective and precise solution under specific conditions but requires careful management and completely safe execution to ensure reliable equipment performance without creating hazards.

Precision Leak Testing (Leak Test)

Precision leak testing is one of the most advanced and sensitive methods for assessing the integrity of pressure equipment like heat exchangers. This test is particularly applicable in industries where even the smallest leak can have serious consequences, including pharmaceuticals, nuclear, high vacuum, and other applications requiring complete sealing.

Among various methods, Helium Mass Spectrometry is the most accurate and widely used technique. In this method, helium gas is used as the tracer material because its small atoms can pass through the tiniest cracks and pores. After injecting the gas inside or around the equipment, the spectrometer measures the leak rate with very high precision, in scales of ppm (parts per million) or ppb (parts per billion). This test can detect microscopic leaks that are undetectable by traditional methods and is therefore used as a standard tool in sensitive industries.

Early and precise detection of such leaks can prevent safety, environmental, or operational hazards and reduce costs associated with production stoppages or emergency repairs.

Scanning and Detection Tools

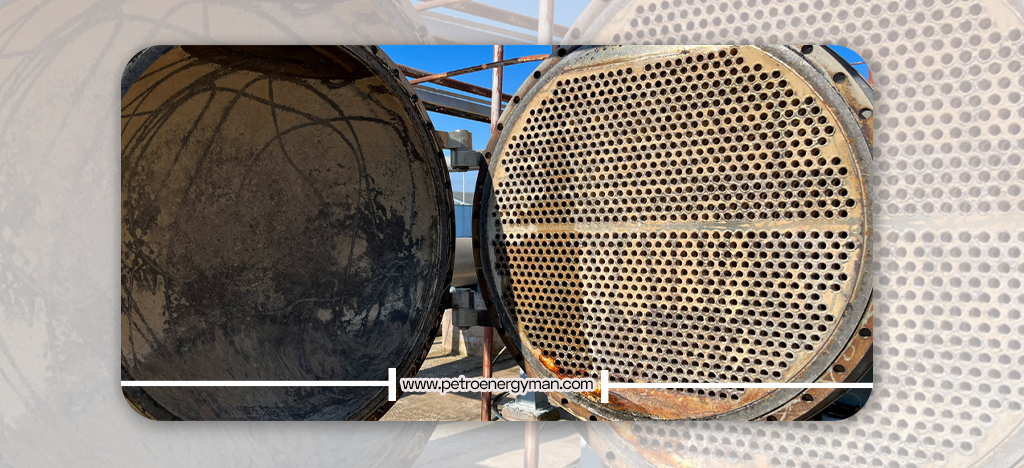

Scanning and detection tools play an important role in monitoring the internal condition of heat exchangers and other pressure equipment. These tools are used to identify damage such as corrosion, cracks, erosion, pitting, and internal cavities and serve as a vital complement to pressure tests, enabling non-destructive and precise evaluation.

Types of Shell and Tube Heat Exchangers

Tube-and-Shell Heat Exchanger are classified based on various criteria such as design standard, fluid flow mechanism, and material of construction, each with its own advantages and specific applications.

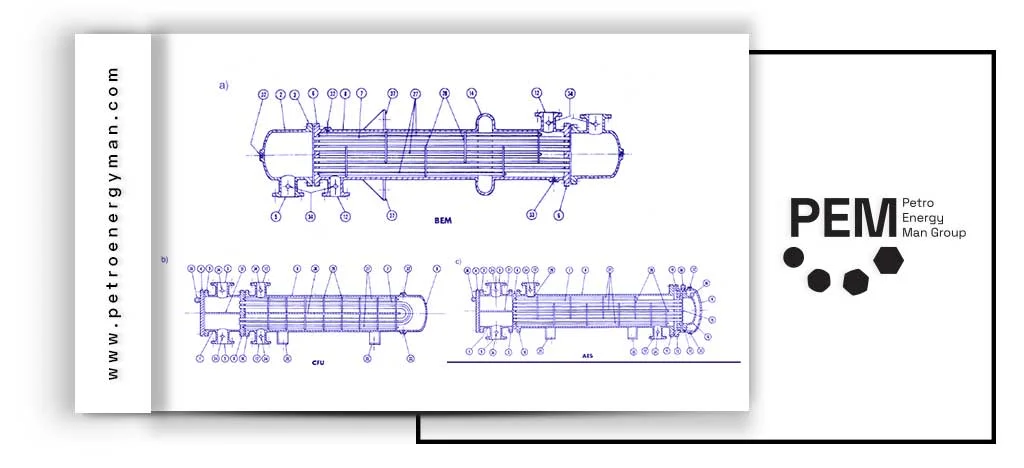

Based on TEMA Standard

According to the TEMA (Tubular Exchanger Manufacturers Association) standard, exchangers are classified based on front/rear head series configuration and shell type. This standard includes different classes, each with specific applications:

- Class B: Tube-and-Shell Heat Exchanger used in chemical processes.

- Class C: Exchangers for general service in various industries.

- Class R: Tube-and-Shell Heat Exchanger designed and used for petrochemical industries and large-scale processes.

Based on Fluid Flow Mechanism

- Shell and tube heat exchangers are also divided into different categories based on how fluids flow within the equipment:

- Parallel Flow: In this type, both fluids move in the same direction, causing the temperature difference between them to gradually decrease along the exchanger.

- Counter Flow: In this case, fluids flow in opposite directions, increasing heat transfer efficiency, commonly used in many applications.

- Cross Flow: In this type, fluids flow perpendicular to each other, typically used in exchangers with specific designs.

- Combined Flow: This involves a combination of the above mechanisms, employed to improve heat transfer and adapt to specific design conditions.

Based on Material of Construction

The selection of the material for shell and tube heat exchangers is based on fluid type, temperature, pressure, and corrosion resistance. This diversity in materials allows exchangers to perform well in very challenging environments and various operating conditions.

Copper: Known for its very high thermal conductivity, commonly used in general applications and situations requiring rapid heat transfer.

Titanium: Due to excellent corrosion resistance, especially in environments containing chlorides and acids, suitable for specific and expensive applications.

Stainless Steel: This material offers good corrosion resistance, and its ease of cleaning makes it a popular choice in food and pharmaceutical industries.

Nickel Alloys: These alloys are used for highly corrosive environments and extreme temperature conditions due to exceptional corrosion resistance and high strength at elevated temperatures.

Carbon Steel: This type of steel is widely used in various industries due to its cost-effectiveness, acceptable corrosion resistance, and suitable thermal conductivity.

Special Materials: Such as graphite, ceramic, composite, and plastic, typically used in special applications requiring specific chemical or thermal resistance.

Based on Operating Pressure and Overall Structure

Exchangers can be designed to withstand different operating

pressures and are categorized by overall structure into the following types:

Double Pipe Exchangers: These are the simplest type, consisting of

a smaller tube inside a larger tube. These exchangers have less heat transfer

surface area and are often used in low-capacity applications or for gaseous

fluids at high pressure.

Air-Cooled Exchangers: These exchangers are equipped with fans and

are used to cool fluids without using liquids.

Plate Heat Exchangers: In this type, multiple plates are used for

heat transfer instead of tubes, offering a more compact structure and higher

efficiency than tubular exchangers.

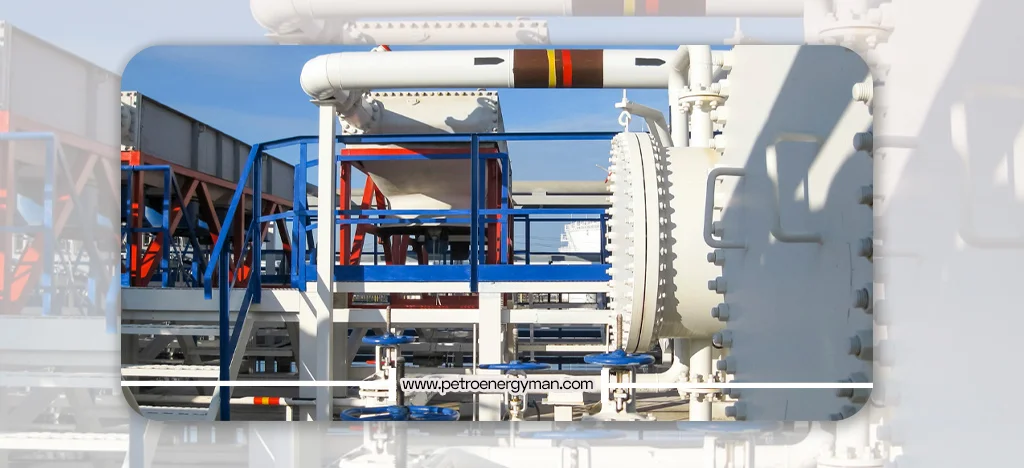

Manufacturers of Shell and Tube Heat Exchangers

Manufacturers of Tube-and-Shell Heat Exchangers operate worldwide

and in Iran. These companies specialize in the design, manufacture, and

installation of various types of heat exchangers for oil and gas,

petrochemical, power generation, food, pharmaceutical, and HVAC industries.

Among manufacturers, Petro Energy Man Holding, with an outstanding

record in designing and producing shell and tube heat exchangers, is recognized

as one of the reputable companies in this industry due to its specialized and

flexible approach. Relying on engineering knowledge and a precise understanding

of market needs, this company has played a significant role in key industries

of the country. Manufacturing high-quality equipment, compliance with

international standards, and providing full services from design to

commissioning are part of Petro Energy Man’s capabilities in providing

professional industrial solutions.

For specialized consultation, technical assessment of your

project’s needs, and ordering custom-built heat exchangers tailored to your

requirements, Petro Energy Man’s experts are ready to assist.

Contact Number: +98 21 5742 3000

Finding Shell And Tube Heat Exchanger Manufacturers Near Me

To find Tube-and-Shell Heat Exchanger manufacturers near you, you can use the following methods:

- Online Search: Using search engines with phrases such as “Tube-and-Shell Heat Exchanger manufacturer in [city or province]”.

- Industrial Associations: Visit the websites of relevant industrial associations (e.g., oil and gas, petrochemical) which may provide a list of manufacturers.

- Industrial Exhibitions: Attend specialized industrial exhibitions where manufacturers of this equipment are present.

- Consulting Specialists: Inquire with engineers, industrial consultants, or partner companies who may have experience working with local manufacturers.

Conclusion

Shell and tube heat exchangers, due to their reliability, efficiency, and flexibility, are the backbone of many industrial processes. With technological advancements, the design and construction of these exchangers are moving towards increased energy efficiency, reduced size, use of more advanced materials, and greater resistance to corrosion and fouling. Additionally, the development of computer simulation and optimization methods has enabled the design of exchangers with higher performance and lower cost.

If you are looking to purchase, design, or consult about Tube-and-Shell Heat Exchangers, you can call +98 21 5742 3000 or contact Petro Energy Man consultants via Instagram ID @petroenergyman.

No comment