Industrial heat exchangers are devices that transfer thermal energy between two different fluids without allowing them to mix. This article explores the main types of industrial exchangers—including plate, shell-and-tube, and finned plate models. It also analyzes key parameters for selecting exchangers, operational challenges such as fouling, pressure drop, and corrosion, and the engineering solutions to address them. Furthermore, the industrial applications of these exchangers in chemical, power generation, food, and HVAC industries are discussed. To gain a deeper understanding of the technical details, advantages, and specialized applications of industrial heat exchangers, continue reading.

What is an industrial heat exchanger?

Industrial heat exchangers are devices engineered to transfer thermal energy between two different fluids—whether liquid or gas—without allowing them to mix. A conductive wall, typically made from metals with high thermal conductivity, separates the fluids and enables efficient heat transfer through the barrier.

The operation of an industrial heat exchanger relies on two primary mechanisms: conduction, where heat moves through the metallic wall, and convection, where the motion of the fluid transfers heat between the wall surface and the fluid itself. The flow paths and surface geometries are carefully designed to maximize temperature differences and contact area, ensuring the highest possible heat-transfer efficiency.

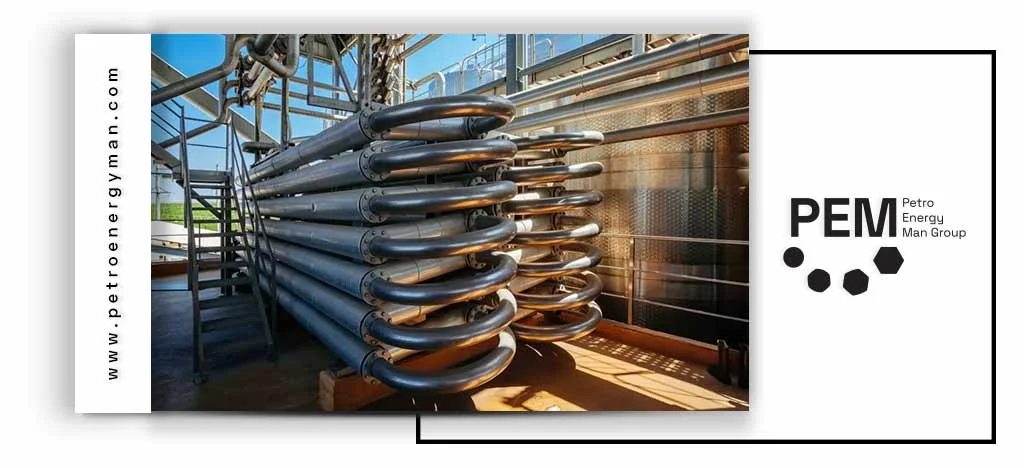

Industrial heat exchangers are manufactured in various configurations such as shell-and-tube, plate, air-cooled, and advanced custom-engineered models. These systems are essential in oil and gas facilities, petrochemical plants, power generation units, chemical processing lines, and food-industry applications. By enabling efficient heat recovery and precise temperature control, they contribute significantly to energy savings and the overall optimization of industrial processes.

If you are looking for more information about the applications of heat exchangers, their types, components, and more, you can visit the Industrial Heat Exchanger page and explore the technical details and practical guidance.

Types of Industrial Heat Exchangers

Get to know the different types of industrial heat exchangers used in exchanger industries.

Plate Heat Exchangers

Plate heat exchangers are built from a series of thin, corrugated plates that separate the hot and cold fluid streams. These plates include corner ports for fluid entry and exit, and they are arranged so that the two fluids flow alternately between them. This structure increases the heat-transfer surface area and creates controlled turbulence, significantly improving thermal performance. Due to their easy maintenance and quick cleaning, plate heat exchangers are widely used in the food and pharmaceutical industries. They are also available in different configurations—such as gasketed and spiral plate models—each engineered for specific fluid conditions and thermal requirements.

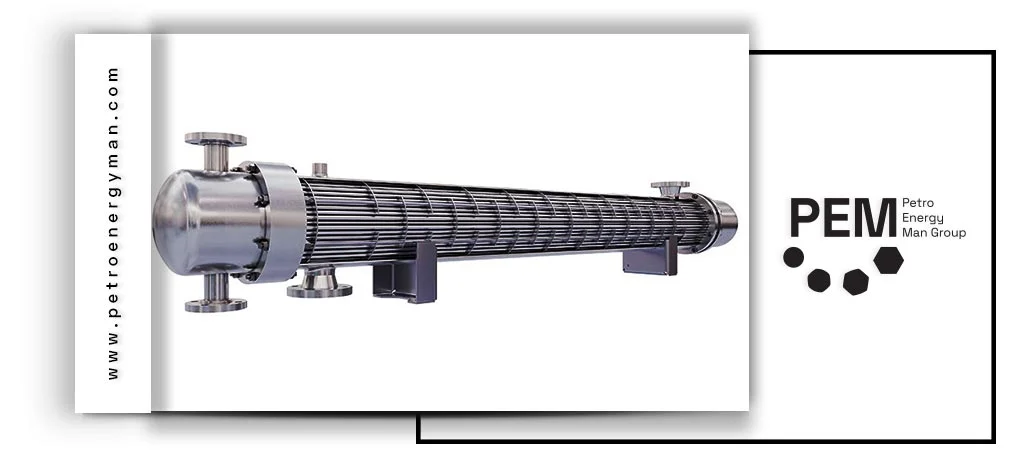

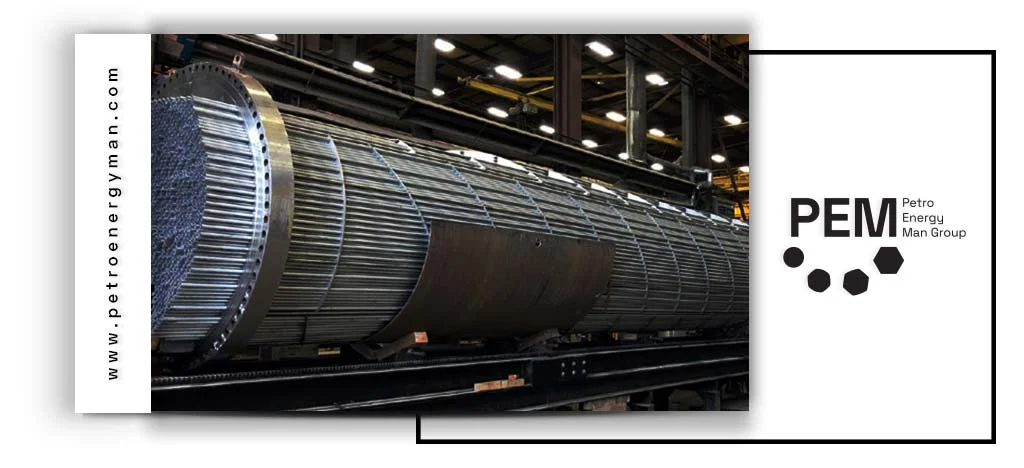

Shell and Tube Heat Exchangers

industrial heat exchangers, particularly shell-and-tube systems, are widely used thanks to their design flexibility and ability to handle high temperatures and pressures in petrochemical plants, power stations, and processing facilities. These units consist of a cylindrical shell that contains a bundle of tubes. One fluid flows inside the tubes, while the other passes through the shell side, enabling heat transfer through conduction and convection. To enhance efficiency and minimize unwanted flow stagnation, internal baffles are installed to direct the shell-side fluid, increase heat-transfer coefficients, and maintain uniform flow distribution. The geometry of the tubes and baffles, flow rate, and temperature difference between fluids are critical factors that determine thermal efficiency and pressure performance.

For specialized consultation on heat exchanger design, fabrication, and engineering solutions, contact Petro Energy Man at 02157423.

Fin Plate Heat Exchangers

industrial heat exchangers like fin plate heat exchangers are engineered with flat plates and corrugated fins that keep the two fluid streams separate while enabling highly efficient surface-based heat transfer. The fins expand the effective contact area and guide the fluid flow into controlled turbulence—enhancing heat transfer without creating excessive pressure drop or stagnant zones.

This configuration boosts the overall heat-transfer coefficient, reduces thermal resistance, and ensures uniform temperature distribution across the unit. Thanks to their high surface-area-to-volume ratio and lightweight structure, fin plate heat exchangers are ideal for applications with strict space or weight constraints such as cooling systems in heavy-duty vehicles, cargo machinery, and aircraft. The engineered fin geometry and plate arrangement also deliver strong mechanical stability, easy cleaning, and simplified maintenance. Another advantage is their ability to operate effectively under high temperature differences and medium-to-high pressures, making them suitable for low-density fluids or high-velocity flow conditions.

The Heat Exchanger Design page provides detailed explanations, measurement methods, and design standards used in the heat exchanger industry, covering in-depth engineering criteria from thermal design calculations to mechanical considerations.

Key Parameters for Selecting Industrial Heat Exchangers

• Operating Temperature and Pressure of Fluids: The choice of exchanger type and the thickness of tubes or shell directly depend on the pressure and temperature, which is a standard design principle.

• Fluid Viscosity and Properties: High viscosity increases pressure drop, while deposition and corrosion influence material selection and cleaning design; these considerations follow API and TEMA standards.

• Flow Rate and Phase Change: Fluid flow rate and phase (single-phase or two-phase) affect tube diameter, exchanger type, and heat transfer coefficient; this is a fundamental principle in heat transfer engineering and exchanger design.

• Thermal and Mechanical Characteristics: Overall heat transfer coefficient (U-value), effective temperature difference (ΔT or LMTD), and wall pressure are key parameters in thermal and mechanical design.

• Material and Corrosion Considerations: Material selection is based on thermal conductivity, chemical resistance, mechanical stability, and cost; this is a standard engineering requirement.

Operational challenges and solutions of industrial heat exchangers

Fouling, pressure drop, and corrosion are among the main challenges of industrial heat exchangers; the following sections discuss each of them and present engineering solutions to address these issues.

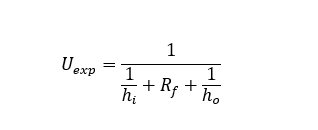

Fouling

Engineering Solutions: Several strategies can be implemented to mitigate fouling:

• Scheduled Periodic Cleaning: Perform maintenance according to SOPs based on operational data to prevent harmful buildup.

• Chemical Cleaning: Use acids, alkalis, and corrosion inhibitors with precise pH and dosage control to dissolve deposits.

• Mechanical Cleaning: Employ tools such as calerings, pigging, or scrubbers to remove physical deposits.

• Fouling Factor Monitoring: Install thermal sensors and measure temperature differences to determine the optimal cleaning intervals and prevent efficiency losses.

Pressure Drop

Engineering Solutions:To minimize pressure drop and maintain optimal performance, engineers use the following strategies:

- Geometric Optimization: Increase tube diameters, reduce flow path length, and adjust the number of passes to lower flow resistance.

- Flow Control: Use manifolds in plate exchangers to prevent dead zones and ensure uniform flow distribution.

- CFD Modeling: Simulate fluid flow to predict pressure drop and design optimized flow channels, balancing heat transfer efficiency with pressure loss.

Corrosion

Industrial heat exchangers can experience corrosion, defined as the deterioration of exchanger materials due to chemical reactions between the tube or shell surfaces and the working fluid. This phenomenon leads to wall thinning, reduced mechanical strength, and decreased heat transfer efficiency, potentially impacting both thermal performance and equipment safety.

Consequences: Severe corrosion can cause mechanical failure, reduce the service life of the exchanger, and increase the risk of leaks or equipment downtime. Over time, it also significantly raises maintenance and replacement costs.

Engineering Solutions:To mitigate corrosion effects, engineers implement the following strategies:

- Alloy Selection: Use titanium in highly corrosive environments and high-temperature conditions, and nickel-based alloys (Hastelloy) for acidic fluids and temperatures above 300°C.

- Thermally Efficient Materials: In non-corrosive conditions, brass or bronze tubes are chosen to maintain good heat transfer while providing adequate resistance.

- Fluid Chemistry Control: Adjust pH levels and add corrosion inhibitors to the fluid to slow degradation and extend the exchanger’s service life.

Applications of Industrial Heat Exchangers

Exchanger industries depend on industrial heat exchangers for efficient thermal management across diverse process applications:

Chemical and Petrochemical Industries

In chemical processes, industrial heat exchangers play a critical role in temperature control, ensuring operational stability and product quality. Within reactors, maintaining a constant temperature is crucial to control reaction rates and prevent severe thermal fluctuations. During distillation and vapor condensation stages, these exchangers create optimal temperature conditions, enabling precise separation of compounds based on boiling points. After reactions, they are used for cooling products, ensuring operational safety and preventing material degradation or quality loss. Thus, industrial heat exchangers are vital throughout production—from initiating reactions to stabilizing the final product.

Power Generation and Power Plants

In power generation, industrial heat exchangers are key to enhancing the performance of thermal systems. In steam and combined-cycle power plants, they are used for condensing turbine exhaust steam and preheating feedwater for boilers. These processes not only improve the plant’s thermal efficiency but also reduce fuel consumption and optimize the overall energy production system.

Food and Beverage Industries

HVAC Systems

In commercial and industrial buildings, industrial heat exchangers are used for precise temperature control and to facilitate heat transfer between cold and warm air streams. By optimizing heat transfer and managing airflow, these systems enhance the energy efficiency of HVAC units, reduce thermal and cooling loads, and ultimately lower operational costs while improving overall system performance.

Wastewater Treatment and Energy Recovery

Industrial heat exchangers enable the recovery of heat from wastewater, which can then be used to preheat incoming streams or provide the necessary temperature for biological reactions. Utilizing these systems leads to significant energy savings, enhances the performance of treatment processes, and plays a crucial role in reducing operational costs while improving overall operational efficiency.

Conclusion

Industrial heat exchangers play a crucial role in heat transfer and energy optimization across industrial processes. This text covered the main types of heat exchangers, key selection parameters, and common operational challenges such as fouling, pressure drop, and corrosion—along with the engineering solutions to address them. Proper use of these systems leads to higher efficiency, lower operational costs, and improved safety and process stability.

No comment