The construction process of a water tube boiler covers all stages from material preparation to full commissioning, with each step explained in detail below.

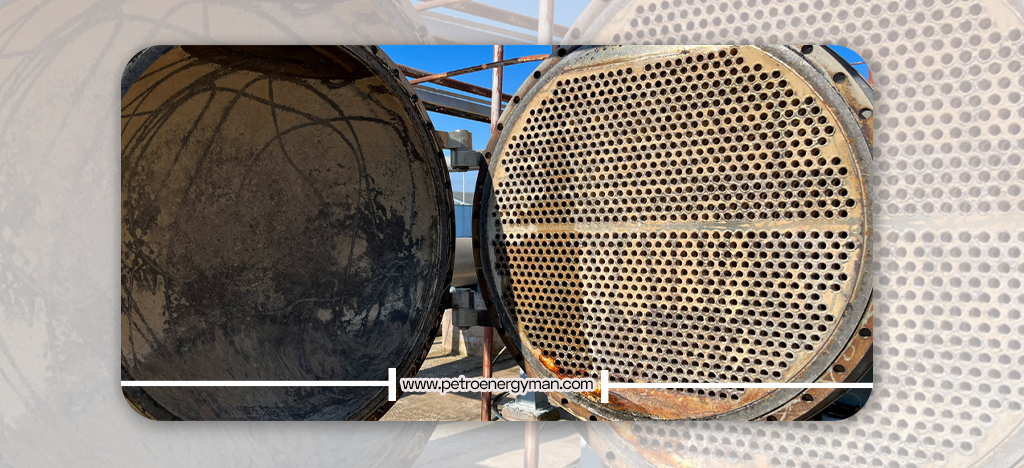

Heat exchanger cleaning is not merely a routine maintenance task; it serves as a vital lifeline for efficiency in heavy industries. When layers of deposits, coke, or biofilms settle on heat transfer surfaces, your exchanger, instead of facilitating processes, becomes a barrier to energy flow, resulting in fuel wastage and increased stress on pumps.In this article, we take a specialized look at common fouling challenges and examine four advanced cleaning methods, including hydrojetting, pyrolysis, chemical cleaning, and ultrasonic technology. If you are looking to optimize the performance of thermal systems and reduce operational costs, this comprehensive guide will help you select the most precise cleaning strategy.

Importance of Heat Exchanger Cleaning

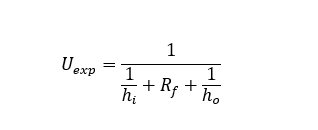

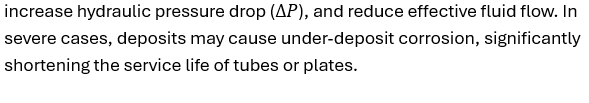

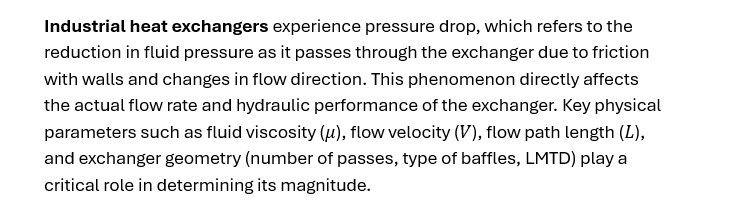

Heat exchanger cleaning is essential because the accumulation of deposits in tubes and components such as boilers, evaporators, and desuperheaters reduces heat transfer efficiency and increases pressure drop. In severe cases, it can even lead to complete blockage. This issue not only decreases the performance of the exchanger but also increases energy consumption for pumping the fluid and raises operational costs.

Professional cleaning, especially using high-pressure methods like hydroblasting, allows for rapid and complete removal of deposits while minimizing unexpected downtime. Regular and periodic cleaning helps maintain optimal exchanger performance and enhances the overall system output.

Careful planning of cleaning schedules and selecting the appropriate method are key to extending equipment lifespan and ensuring stable operation across various industries. This approach also prevents unplanned shutdowns. Moreover, research into deposit-resistant materials and advanced monitoring methods enables better management of fouling and reduces operational costs.

Methods of Heat Exchanger Cleaning

Choosing the appropriate method for cleaning heat exchangers depends on the type of deposits, the material of the exchanger, and operational constraints. Below, we explain the four main cleaning methods used for heat exchangers.

High-Pressure Hydrojet or Hydroblasting

Hydrojetting, also known as industrial water jetting or hydroblasting, is an effective and chemical-free method for removing stubborn deposits and heavy contamination from heat exchanger surfaces. This process involves directing a high-pressure water stream, typically in the range of 10,000 to 40,000 psi, onto the interior of tubes or exchanger plates.

Heat exchanger cleaning with high-pressure water allows the removal of deposits such as metal oxides, sludge, oil residues, and tough organic compounds without damaging the base metal. Key advantages of this method include exceptional cleaning power for adhesive and resilient fouling. Additionally, using water as the cleaning agent is more environmentally friendly and produces minimal chemical waste. The speed of the operation also helps reduce equipment downtime. Engineers and operators must carefully adjust water pressure and select the proper nozzle to prevent erosion or damage to the tube walls.

Thermal Cleaning

Thermal cleaning, sometimes referred to as pyrolysis, is a method used to remove organic deposits from heat exchangers by applying high temperatures. In this process, the heat exchanger or its components are placed in furnaces or specialized equipment capable of providing controlled heat. The high temperature breaks down the structure of organic deposits and oxidizes them, converting them into ash that can be easily removed from the exchanger surface through mechanical cleaning or air blowing.

Heat exchanger cleaning is particularly effective for deposits primarily composed of organic materials, such as polymers, heavy carbon, or coke. Key advantages include a significant reduction in deposit volume to ash and the ability to clean multiple components simultaneously. However, the main challenge in thermal cleaning is precise temperature control to prevent damage to the mechanical properties and metal structure of the exchanger. Excessive heat can cause warping, deformation, or reduced material strength. Therefore, for manufacturers and operators, understanding the material composition and maximum allowable temperature of the exchanger is essential before selecting this method. This technique is less effective for inorganic deposits, such as mineral scales or salts, and may require complementary cleaning methods.

Chemical Cleaning

Chemical cleaning is one of the most common methods for removing a wide range of deposits from heat exchangers. This process involves circulating specific chemical solutions—such as acids, alkalis, detergents, or chelating agents—through the fluid pathways of the exchanger. The chemicals react with the deposits, dissolving them or suspending them for easy flushing.

Industrial heat exchanger cleaning provides a major advantage in its ability to remove complex fouling, including mineral, organic, and biological deposits. This method can reach all areas of the exchanger, even locations with limited physical access, ensuring thorough and comprehensive cleaning. Laboratory tests have confirmed that chemical cleaning can completely eliminate mineral scales and restore heat transfer efficiency to its original state.

However, selecting the correct chemical and formulation based on the type of deposit and material of the exchanger is critical. Using the wrong chemical can result in corrosion or irreversible damage to the equipment. Additionally, proper handling and disposal of chemical waste must comply with environmental regulations to ensure safety and sustainability.

Ultrasonic Cleaning

Industrial heat exchanger cleaning can also be achieved using ultrasonic technology, an advanced and non-contact method that employs high-frequency sound waves (typically between 20 and 400 kHz) to remove deposits and contaminants from heat exchanger surfaces.

The ultrasonic waves propagate through a cleaning liquid—usually water or a mild detergent solution—and create millions of tiny bubbles. These bubbles rapidly expand and collapse, forming a cavitation process that effectively cleans the heat exchanger surface.

The primary advantage of ultrasonic cleaning is its ability to provide deep and uniform cleaning of components. This method is highly effective even on parts with complex shapes, narrow gaps, and areas that are difficult to access. This capability is due to the penetration of ultrasonic waves deep into the materials.

This technique is non-invasive and non-abrasive, so it does not damage sensitive exchanger surfaces. Additionally, its high efficiency reduces the need for strong chemicals, often achieving effective cleaning with just water or mild solutions. This makes ultrasonic cleaning a more environmentally friendly option.

Challenges of Heat Exchanger Cleaning

Limited access to internal surfaces, the hardness and variety of deposits, and the need to minimize production downtime are among the most important factors that engineers must consider to ensure equipment operates in a stable, efficient, and safe manner.

By identifying these challenges, industrial operators can implement tailored cleaning strategies that not only maintain optimal system performance but also reduce operational costs and extend equipment lifespan.

Limited Access and Complex Geometry

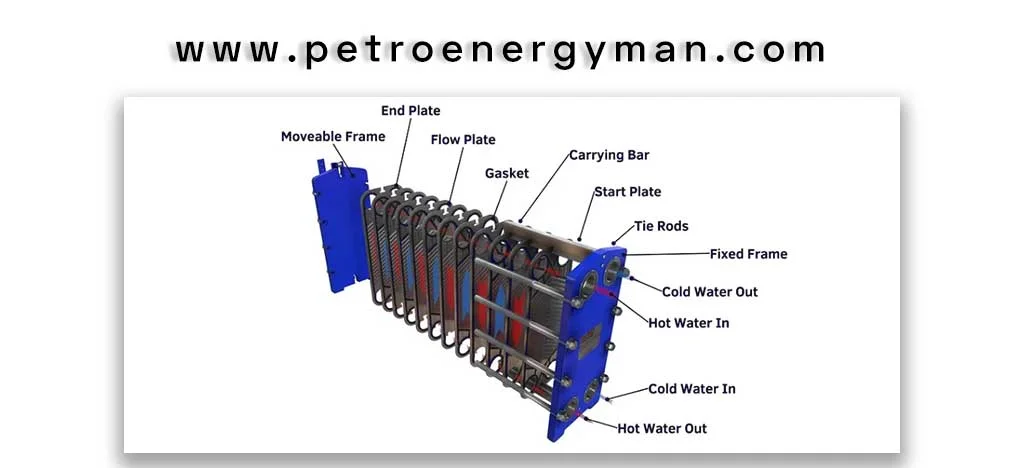

Heat exchanger cleaning is particularly challenging because heat exchangers come in various types, including plate, spiral, and finned-tube models. Many of these designs, especially modern ones optimized for maximum heat transfer efficiency, feature complex flow paths, small-diameter tubes, tightly packed fins, or closely spaced plates. These intricate geometries make physical cleaning methods, such as scraping or using handheld water or air jets, very difficult or even impossible. Deposits accumulate in corners, gaps, and dead zones, where direct access is almost impossible. This limited access increases the need for non-invasive or chemical cleaning methods capable of reaching all internal surfaces of the exchanger.

Hardness of Deposits

Heat exchanger cleaning is particularly challenging due to the variety and nature of deposits. Mineral deposits, such as carbonates (e.g., calcium carbonate), silica, metal oxides (e.g., iron oxide), and sulfates, can be extremely hard and adhesive to exchanger walls. Removing them usually requires strong acids or high-pressure mechanical methods.

Organic deposits include greases, oils, polymers, and coke, which form sticky layers and make cleaning difficult. These deposits are typically removed using alkaline solutions or specific solvents.

Biological fouling (biofouling) involves the growth of microorganisms, algae, and bacteria that create biofilm layers, increasing thermal resistance and reducing fluid flow. These types of deposits are removed using biocides and antimicrobial agents.

Selecting the appropriate cleaning method depends heavily on the type and severity of the fouling. Some deposits are so resistant that even strong chemical solutions cannot remove them entirely, and using inappropriate substances can damage the exchanger. Therefore, accurately identifying deposit types and applying suitable cleaning techniques is key to maintaining optimal performance and extending the lifespan of heat exchangers

Extended Production Downtime

Heat exchanger cleaning—whether performed chemically or mechanically—often requires a full or partial production shutdown. Such interruptions reduce output because the plant cannot operate at full capacity or may need to stop the production line entirely. Additionally, labor costs for maintenance personnel, cleaning operations, and material expenses—including chemicals, water, energy, and waste disposal—also increase.

The cleaning process itself is time-consuming; the time needed for cooling, washing, inspection, and reassembling the exchanger can be substantial. For this reason, the development of online cleaning and Clean-in-Place (CIP) methods has become increasingly important. These techniques are designed to minimize downtime while maintaining exchanger performance without a full shutdown. In many industries, optimizing cleaning schedules and managing energy across heat exchanger networks are key strategies to reduce costs and improve operational efficiency.

Conclusion

Modern heat exchanger cleaning represents the intersection of energy cost reduction and equipment longevity. This review highlights how high-pressure hydrojetting addresses tough deposits, thermal cleaning targets organic compounds, chemical processes reach hard-to-access areas, and ultrasonic systems protect sensitive components—each playing a vital role in industrial maintenance.

The significance lies in the fact that well-maintained heat exchangers, by reducing pressure drop and restoring heat transfer efficiency, directly ensure production stability and prevent unexpected downtime, which can impose substantial costs on industrial operations.

Brazed plate heat exchangers are compact devices designed for heat transfer between two fluids without direct contact, and they have extensive applications across various industries. This text examines their technical structure, performance advantages, materials used, and main application areas. It also details the role of BPHEs in HVAC systems, cooling, energy and utility services, industrial machinery, and refrigeration, including chillers, heat pumps, waste heat recovery, oil cooling, and refrigerated transport systems.

Brazed Plate Heat Exchangers: Technical Overview

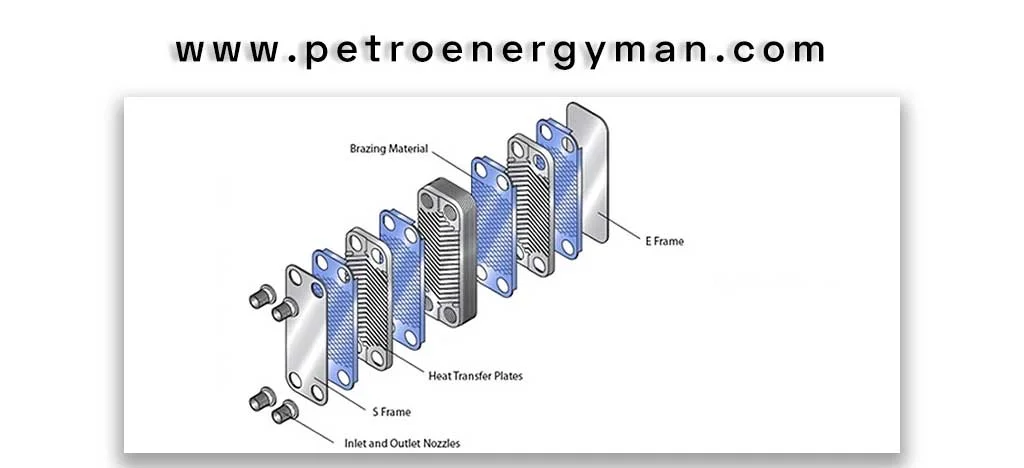

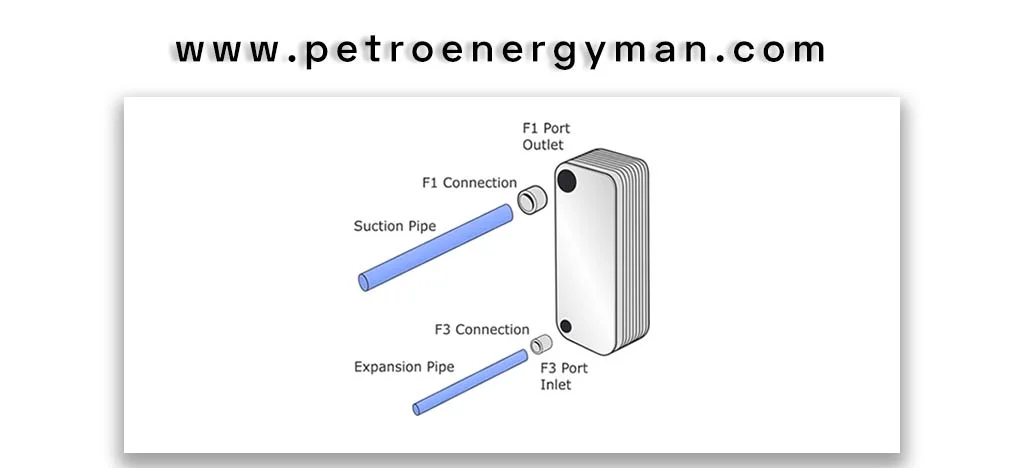

Brazed plate heat exchangers are compact devices designed for efficient heat transfer between two fluids without direct contact. These exchangers are constructed from corrugated stainless steel plates, typically AISI 316, which are brazed at contact points using filler metals such as copper or nickel. The result is a fully sealed unit that can withstand high pressures and temperatures without the need for gaskets.

The manufacturing process involves stacking the plates with the filler metal and heating them in a vacuum furnace at around 450°C. This melts the filler, creating strong and durable joints. The design forms two independent fluid circuits, ensuring effective heat transfer. The corrugated pattern of the plates not only increases the heat transfer surface but also directs fluid flow to maximize contact with the plate surfaces, improving thermal efficiency.

The angle of the plate corrugations plays a key role in determining heat transfer rates and pressure drop. This corrugated design optimizes fluid flow, enhances mechanical strength, and allows the use of thinner plates, resulting in more compact exchangers.As a result, BPHEs offer high thermal performance and are ideal for industrial heating systems, refrigeration, and HVAC applications.

Technical Advantages of Brazed Heat Exchangers

Brazed plate heat exchangers, due to their compact design and high thermal efficiency, are considered one of the most efficient types of industrial heat exchanger. By combining operational flexibility with the use of durable materials, these units represent an optimal choice for production processes that face space limitations while requiring maximum heat transfer performance as an operational priority. Ease of maintenance and effective space optimization have given these systems a prominent position in large-scale industrial projects. In the following sections, each of these advantages will be examined in detail from a technical perspective.

Compactness and Space-Saving

Thanks to their engineered, compact design, brazed plate heat exchangers are an excellent choice for applications where space is limited. Their small size and lightweight construction provide significant flexibility in system design and simplify installation. Technical studies show that these exchangers can reduce weight and volume by up to 90% compared to shell-and-tube heat exchangers with similar performance capacity. This optimized footprint not only conserves valuable equipment space but also significantly lowers transportation, handling, and project implementation costs.

Operational Flexibility

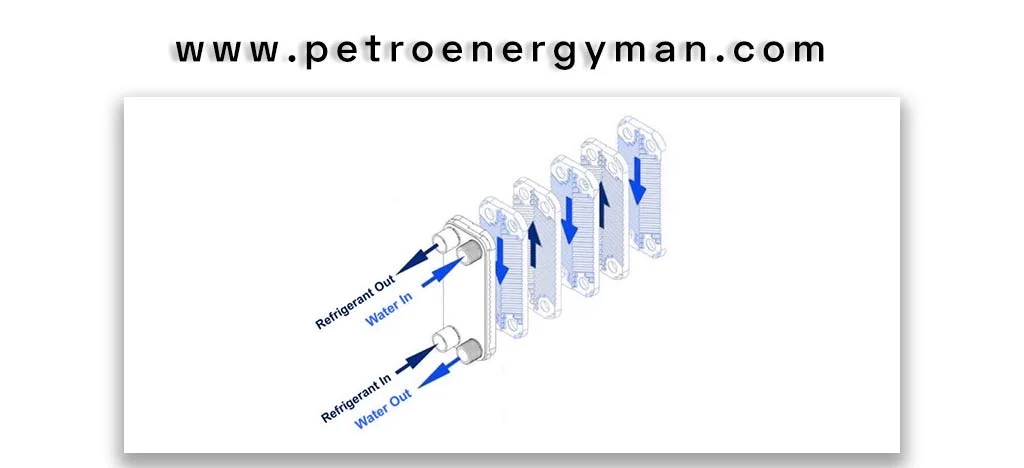

Brazed heat exchangers offer exceptional operational flexibility, allowing them to be designed and configured to meet the specific needs of each application. The ability to select different types of connections and adjust the plate pattern enables engineers to tailor the exchanger precisely to operational conditions and required capacity. Additionally, choosing different flow arrangements—such as co-current or counter-current flow—optimizes heat transfer and enhances overall efficiency.

High Thermal Efficiency

These exchangers deliver significantly higher thermal performance compared to shell-and-tube heat exchangers, while occupying up to 75% less space and footprint. This efficiency is achieved through a large heat transfer surface, induced turbulence, and the possibility of counter-current flow design. The compact design allows for a high heat transfer area in a limited space and supports operation under high fluid pressures. The improved thermal efficiency of BPHEs directly reduces energy consumption and enhances heat recovery in industrial processes.

Durable and Optimized Materials

Brazed plate materials ensure the long-term durability and performance of these heat exchangers. The channel plates are typically made from AISI 316 stainless steel, providing excellent corrosion resistance, while pure copper or nickel alloys are used for brazing to create strong and reliable joints.

In specialized applications or environments with aggressive fluids, using all-stainless steel or high-molybdenum alloys such as SMO 254 offers superior corrosion resistance and maintains surface cleanliness. These materials make BPHEs compatible with a wide range of fluids, including mineral and synthetic oils, organic solvents, water, glycol/water mixtures, and various refrigerants.

Maintenance and Serviceability

One of the main advantages of brazed plate heat exchangers is their simple maintenance. The robust, gasket-free structure minimizes the risk of leaks and reduces the need for frequent servicing. The natural turbulence of fluid inside the exchanger helps keep the plates clean, eliminating the need for constant cleaning in many applications. In systems with a high risk of fouling, cleaning-in-place (CIP) methods can be applied to maintain efficiency and extend the exchanger’s service life.

Overall, the combination of compact design, high thermal efficiency, operational flexibility, and durable materials makes brazed plate heat exchangers a highly reliable option for industrial applications. In this context, collaboration with experienced and specialized heat exchanger manufacturers plays a key role in ensuring system performance, as the precise compatibility of the equipment with the type of fluid, operating pressure, and process requirements can only be achieved through such expertise, guaranteeing optimal long-term performance.

Applications of Brazed Plate Heat Exchangers

Brazed plate heat exchangers have key applications across HVAC, energy, and utility systems.

HVAC & Air Conditioning

In air conditioning systems, these units play a central role in temperature management.

- Industrial and Commercial Chillers: Heat exchanger brazed plate units in industrial and commercial chillers function both as evaporators—absorbing heat from water or process fluids—and as condensers—transferring heat to the environment or cooling towers. Their compact size minimizes chiller installation space, which is especially important in space-constrained industrial environments. High efficiency reduces energy consumption to achieve the desired cooling capacity, lowering operational costs and simplifying compliance with strict energy standards. Optimized channel design and high-pressure tolerance also allow engineers to use low-global-warming-potential (Low-GWP) refrigerants effectively.

- Refrigerated Air Dryers: Brazed plate heat exchangers cool compressed air and condense its moisture. Accurate heat transfer is critical to prevent freezing and maintain low dew points, making them an ideal solution for these systems.

Energy & Utilities

- Heat Pumps: Brazed heat exchanger units in air-to-water or ground-to-water heat pumps transfer heat between a source (ambient air or ground fluid) and building heating systems or domestic hot water. Their ability to achieve low approach temperatures and high efficiency improves the heat pump’s coefficient of performance (COP), resulting in significant energy savings.

- Waste Heat Recovery: Brazed plate heat exchangers are used in waste heat recovery systems, including Organic Rankine Cycles (ORC), to convert excess process heat into useful energy such as electricity or heating. Optimized design and high thermal efficiency allow maximum energy extraction even from low-temperature streams, boosting overall system performance.

- Solar Water Heaters and Boiler Systems: They serve as fluid separators and heat transfer units to domestic or boiler feed water, enhancing system safety, efficiency, and overall equipment performance.

Machinery Equipment

- Hydraulic and Lubrication Oil Cooling: In equipment such as large gearboxes, wind turbines, and plastic injection molding machines, hydraulic and lubrication oils heat up during operation. These heat exchangers cool the oils, preventing oil degradation, reducing component wear, and extending equipment lifespan.

- Laser Welding Machines: Precise and stable cooling of laser sources and sensitive optical components ensures consistent laser beam quality and protects expensive parts from damage.

Refrigeration

- Industrial and Commercial Refrigeration Units: Brazed heat exchanger units in air-to-water or ground-to-water heat pumps transfer heat between a source (ambient air or ground fluid) and building heating systems or domestic hot water. Their ability to achieve low approach temperatures and high efficiency improves the heat pump’s coefficient of performance (COP), resulting in significant energy savings.

- Refrigerated Transport: Limited space and the need to maintain consistent temperatures in trucks and refrigerated containers make these exchangers an ideal choice for cooling systems. Their robust design and high resistance to vibration and shocks ensure stable and reliable operation.

Conclusion

Brazed plate heat exchangers are highly efficient and compact devices used in HVAC systems, energy applications, machinery, and refrigeration. They enable effective heat transfer, reduce energy consumption, and offer easy maintenance. By improving system efficiency and extending equipment lifespan, these exchangers play a key role in enhancing performance and operational savings across various industries.

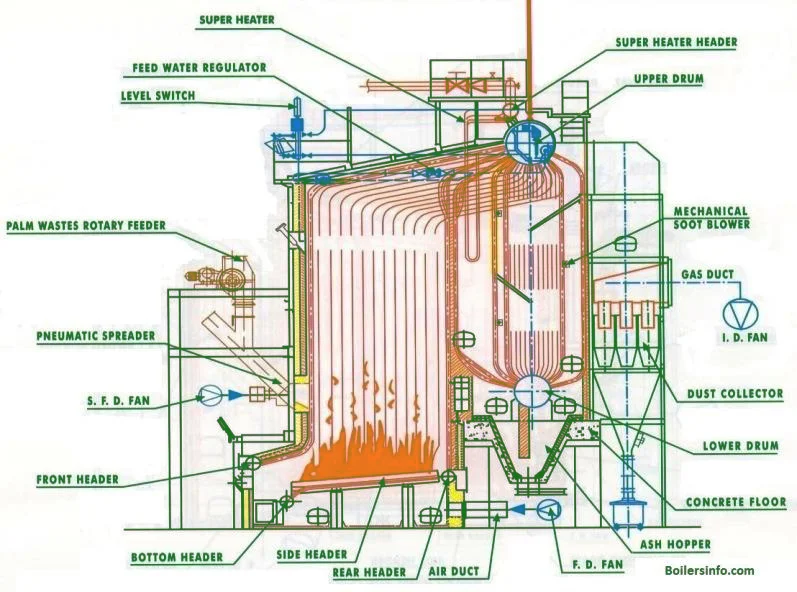

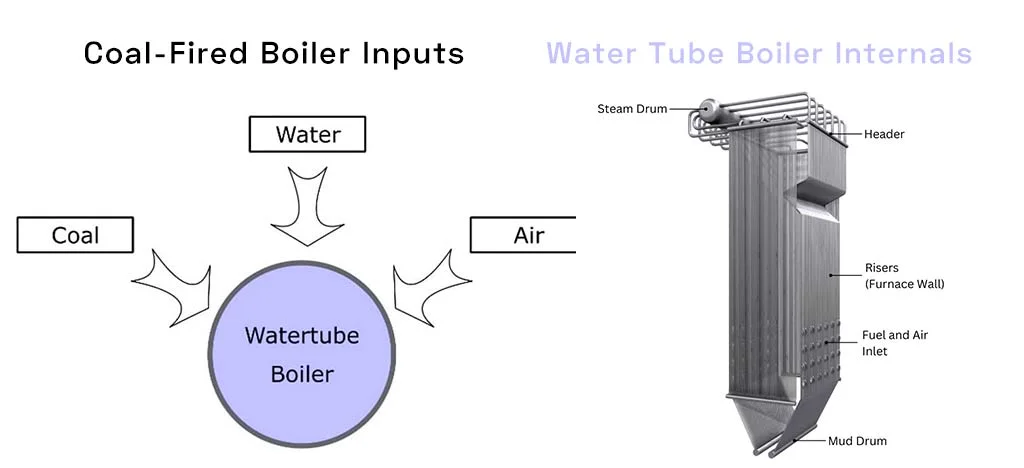

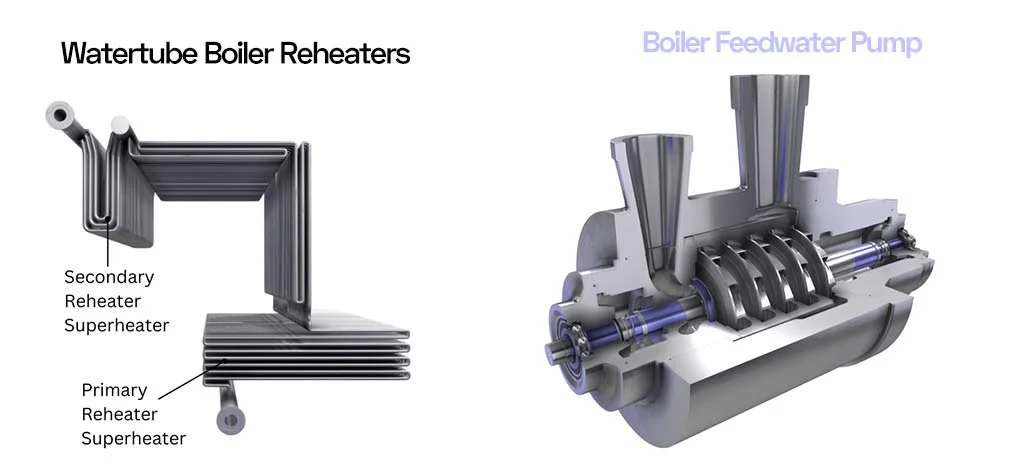

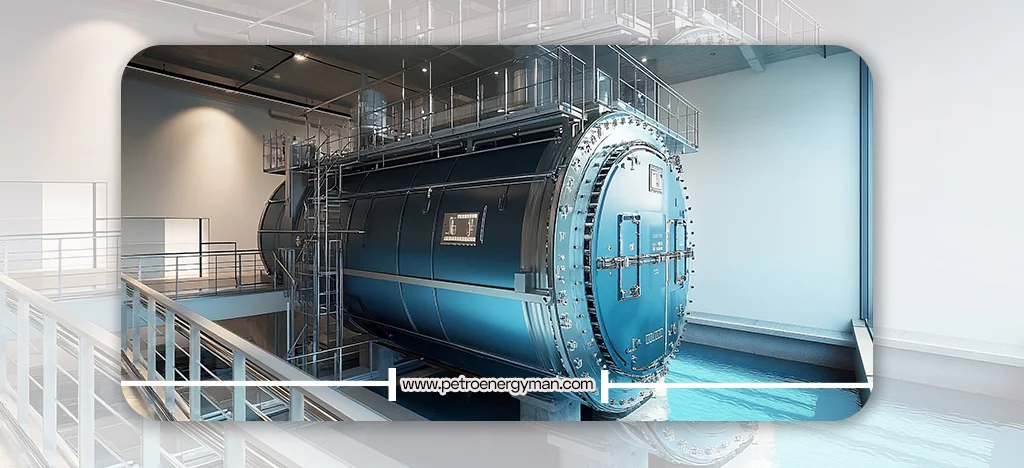

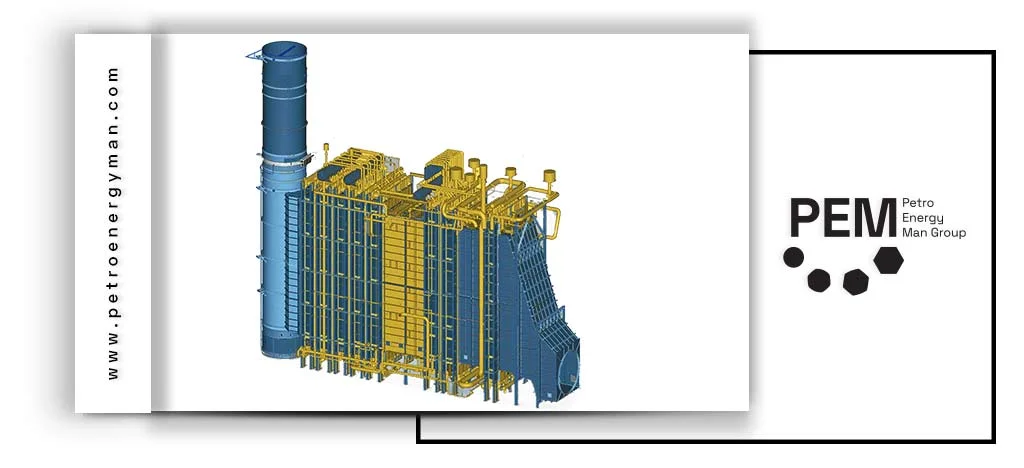

What is a Water-Tube Boiler?

A Water-tube boiler is a type of industrial steam boiler in which water flows inside the tubes while the hot combustion gases pass outside the tubes. As water enters the tubes, it absorbs heat from the combustion gases and is converted into steam. In this system, heat transfer takes place between the cold fluid (water) inside the tubes and the hot fluid (combustion gases) outside the tubes, resulting in the production of steam at high pressure and temperature. The operating pressure range of watertube boiler is typically 10–80 bar, and the temperature range is 180–480 ℃.

Types of Watertube Boilers

Water-tube boilers are designed and manufactured in different configurations to meet spatial limitations, various steam requirements (capacity, pressure, temperature), ease of installation and maintenance, and other customer needs.

| Classification Type | Category | Description |

|---|---|---|

| Working Fluid | Water | Most watertube boilers use water as the working fluid to generate steam. |

| Fuel Type | Single or Multi-fuel | Can operate using natural gas, diesel, or a combination of fuels. |

| Customized Fuels | Can be redesigned to use process gases, hydrogen, or heavy fuels. | |

| Circulation Type | Natural Circulation | Flow is driven by the density difference between water and steam. |

| Forced Circulation | Circulation is maintained using pumps for better flow control. | |

| Structure | O-Type | Dual flue gas paths, balanced weight distribution, used in portable boilers. |

| A-Type | Compact structure with two gas passes, used for limited space setups. | |

| D-Type | Single flue gas path, high efficiency, commonly used in industries. | |

| Application | Package Boiler | Used in factories and industries for process steam; small to medium capacity. |

| Utility / Hanging Boiler | Large boilers used in power plants to generate turbine steam. | |

| HRSG (Heat Recovery Boiler) | Recovers heat from gas turbines or industrial exhaust gases. | |

| Other Classifications | Tube Arrangement | Boilers can have horizontal or vertical tube configurations. |

| Installation Type | Can be modular, skid-mounted, or field-erected. | |

| Design Standard | Manufactured under standards such as ASME or EN 12952. |

Classification Based on Working Fluid

The working fluid of Watertube Boilers is typically water.

Classification Based on Fuel

Conventional watertube may be designed as single-fuel or multi-fuel units, most commonly capable of using natural gas and diesel oil. Petroenergyman also offers redesign solutions for watertube boilers to operate with process gases, hydrogen, and heavier fuels to meet specific customer requirements.

Classification Based on Fluid Circulation

Water circulation in a boiler refers to the driving force that moves the water–steam mixture. This driving force may be natural circulation, created by the density difference between water in the downcomers and risers along with the thermal head. When natural circulation is insufficient, a circulating pump is required, in which case the boiler is referred to as a forced circulation boiler.

Classification Based on Structure

In O and A types, the flue gases exit the furnace located in the center, turn 180 degrees, and are then divided into two streams entering the tube banks. One of the advantages of these designs is better weight distribution, making them suitable for portable boilers.

However, for general industrial applications, these two designs are nearly obsolete, with the D-type being preferred due to its higher thermal efficiency. In D-type boilers, widely used across industries, the entire flue gas flow after leaving the furnace passes into the convective heat transfer section. The advantage of the D-type is the elimination of flow distribution issues across dual paths.

Classification Based on Application

Water-tube boilers can be categorized into three main types:

- Package Boilers

- Hanging (Utility) Boilers

- Heat Recovery Steam Generators (HRSG)

Utility boilers are typically used in power plants to supply steam for turbines, featuring very high capacity and pressure. Package boilers generally have lower capacity and pressure and are mainly intended for internal process steam consumption in industries. HRSG boilers are often employed in gas power plants to recover heat from the hot exhaust gases of gas turbines, but they are also used in other industries to recover energy from high-temperature waste gases. A common feature among all three types is that water flows inside the tubes while hot gases pass around them.

Other Classifications

Beyond the above, water tube boilers may also be classified by tube arrangement, installation method, and construction standards such as EN 12952 or ASME. The diversity in watertube designs allows manufacturers to deliver optimized solutions for specific industrial needs.

Advantages and Disadvantages of Water-Tube Boilers

Watertube boilers offer

significant advantages that make them the ideal choice for many heavy-duty

industrial and power generation applications. However, like any technology,

they also pose challenges, for which petroenergyman provides tailored solutions based

on years of experience in boiler manufacturing.

Advantages of WaterTube Boilers

High pressure and capacity, high steam generation rate, safety under high pressures, high efficiency, ease of maintenance, variety in design and construction, the ability to use different fuels, and controllability are among the advantages of water tube . These advantages will be explained in detail in

High Pressure and Capacity

One of the most important benefits of water tube boilers is their ability to produce steam at very high pressures and capacities. Package water-tube can deliver steam up to 80 bar and 180 t/h, while utility hanging boilers can reach up to 160 bar and capacities well above 180 t/h.

Safety at High Pressures

Unlike fire-tube boilers, which store a large volume of water in a single shell and require strict safety precautions to prevent explosions, water-tube boilers contain smaller volumes of water distributed across multiple tubes. In case of tube rupture, only a small amount of steam and water is released, significantly reducing explosion hazards.

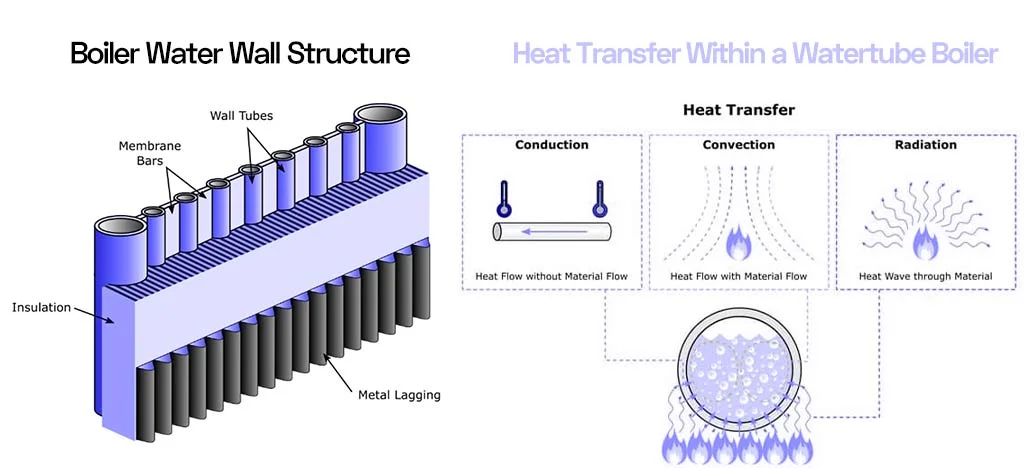

High Efficiency

The design of water-tube boilers enhances heat transfer between hot gases and the working fluid. With proper insulation, thermal efficiency can exceed 92%, translating into lower fuel consumption and reduced operating costs.

Ease of Maintenance

These boilers are designed to provide accessibility for inspection, maintenance, and modifications.

Flexibility in Design and Construction

Flexible tube arrangement and overall configuration

allow the manufacture of boilers optimized for specific industrial

requirements, including spatial constraints. In addition to standard designs,

petroenergyman offers custom redesign services using specialized expertise

Fuel Flexibility

Water tube boilers can operate on a wide range of fuels, including natural gas, heavy fuel oil, solid fuels, biomass, and hydrogen, enabling industries to optimize fuel choices based on availability and cost.

Controllability

These boilers can operate with multiple burners, either independently or in parallel, and are often integrated with Programmable Logic Controllers (PLC) for precise load management and reduced greenhouse gas emissions.

Challenges of Water Tube Boilers

The water-tube boiler has certain drawbacks or challenges, including manufacturing and installation quality requirements, high initial cost, and the need for continuous inspection and monitoring.

Manufacturing and Installation Quality

Due to their complex design, watertube boilers require high-quality raw materials to ensure both thermal conductivity and mechanical strength. Precise fabrication and optimized design are key challenges.

In PetroMen-designed water-tube superheater tubes are commonly manufactured from SA240 T22, while evaporator tubes are made from SA210 A1, providing enhanced heat transfer, higher efficiency, and durability under thermal stress. These material selections may vary depending on project requirements.

Additionally, the large dimensions of watertube make transportation difficult, requiring on-site assembly, which adds to project complexity and scheduling. PetroMen addresses this by applying documented Fabrication, Shipping, and Erection Procedures, along with well-defined schedules to facilitate the process.

High Initial Cost

The complexity of manufacturing, the need for advanced engineering materials, and precision production processes significantly increase the capital investment compared to fire-tube boilers. PetroMen mitigates this by optimizing material use and employing advanced insulation methods, such as Ceramic Fiber, to reduce both capital and operating costs.

Need for Continuous Monitoring and Control

The operation, maintenance, and servicing of these boilers require advanced technical expertise due to their engineering complexity. Personnel must undergo continuous training, and systems must be carefully monitored. For this reason, Petromen boilers are covered by a full warranty for up to two years, during which the company not only provides the necessary operational training but also guarantees boiler performance for up to 200,000 Equivalent Operating Hours (EOH).

Design Principles of Water-Tube Steam Boilers

The design of water-tube steam boilers is a complex and precise engineering process aimed at meeting the specific needs of customers while ensuring safe and efficient operation

Initial Design Steps and Considerations

The design process begins with the collection of initial data regarding the required steam output, outlet steam temperature, and operating system pressure. Based on this information, key parameters such as the approximate dimensions of the boiler, burner capacity, fan capacity, pump power, tanks, and other preliminary specifications are determined. Additionally, the available space for installation and the required footprint of the boiler system are defined. This approach ensures that the boiler delivers the final steam output while meeting the specific operational requirements of each project.

Key Design Parameters

Once the initial requirements are established, designers focus on detailed technical parameters. These include design pressure, design temperature (for various sections such as the shell, tubes, plates, and fins), flue gas inlet temperature, effective radiant surfaces, and minimum thickness requirements for pressure parts (drums, tubes, piping, and tanks).

A critical parameter in water-tube boilers is the Circulation Ratio (CR). This ratio indicates the level of water recirculation in the system to ensure adequate water-to-steam conversion and prevent overheating of the tubes.

Role of Standards and Software

To guarantee safety, reliability, and efficiency, boiler design must comply with internationally recognized codes and standards. The ASME Boiler and Pressure Vessel Code provides practical and safety guidelines for the construction and testing of steam boilers, while NFPA standards (National Fire Protection Association) are applied to mitigate combustion-related hazards. Additional national and international standards may also be applied.

Advanced engineering software such as ANSYS, FireCAD, PPSD, PDMS, EES, SolidWorks, Catia, and AutoCAD are used to facilitate and improve design precision.

Efficiency Enhancements in Design

Various methods are applied during the design stage to increase the overall efficiency of steam boilers. The higher the efficiency, the more steam can be produced with lower fuel consumption and reduced energy losses.

The extensive heat transfer surface area in water-tube boilers—due to water flowing inside tubes surrounded by hot gases—significantly improves efficiency. In general, the efficiency of watertube boilers can reach 92–95%.

Additional auxiliary equipment such as economizers (for preheating feedwater), superheaters (to increase saturated steam temperature to superheated levels), increased furnace pressure (to improve heat transfer), and deaerators (for removing dissolved gases in water) can further enhance performance. Tube arrangement and layout are also carefully optimized to maximize heat transfer.

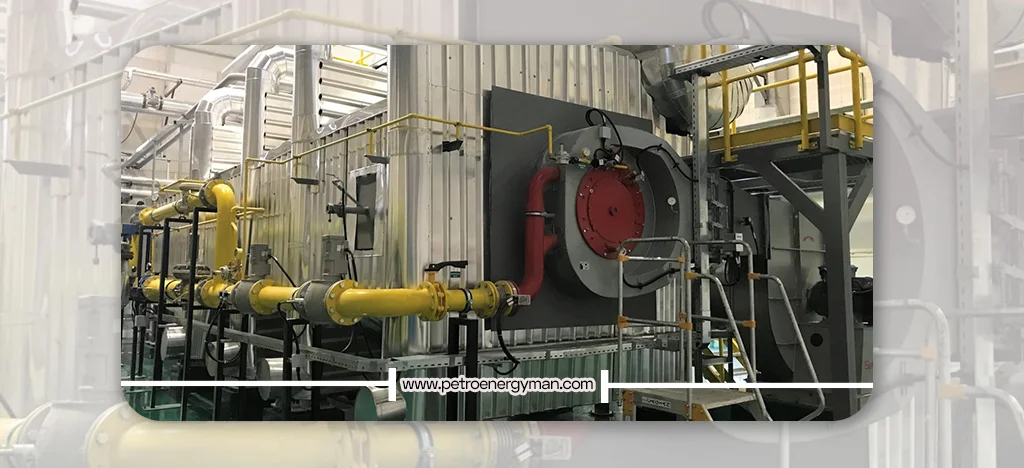

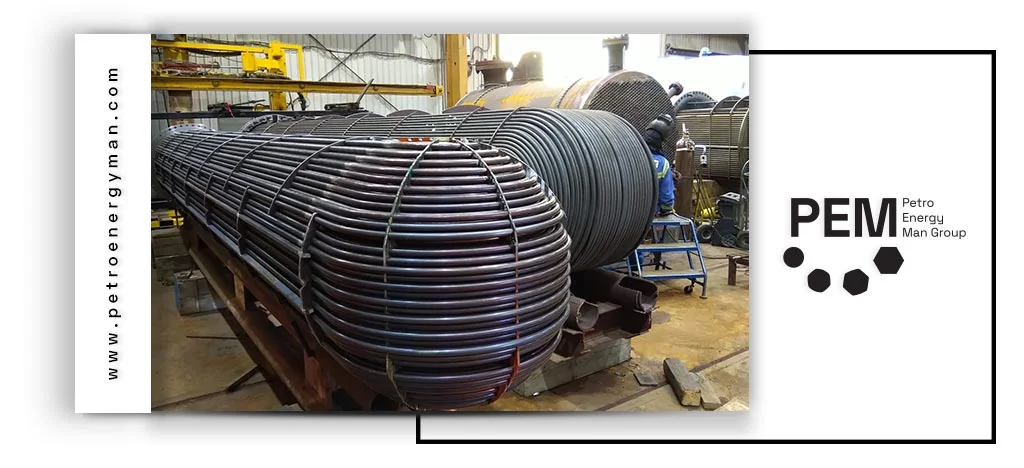

Manufacturing Process of Water-Tube Boilers

Key Fabrication

Processes

- Raw Material Procurement: Main components include seamless alloy steel tubes, steam and water drums (large heavy steel parts), the furnace (combustion chamber), and auxiliary parts such as superheaters, economizers, and control/safety systems, sourced from the highest-quality materials available both domestically and internationally.

- Cutting and Drilling: Steel plates are cut using high-precision CNC cutting machines. Drum drilling is carried out in several stages according to Petromen’s proprietary drilling procedures.

- Rolling and Bending: Cut steel plates are rolled and bent into the required shapes. Water tubes may also undergo bending processes as necessary.

- Main Assembly: Bent and cut steel parts are assembled with high precision.

- Welding: Pressure parts such as drums and joints are welded using automated Submerged Arc Welding (SAW) to ensure maximum weld integrity and quality. Tube-to-drum connections are typically achieved by tube expansion (rolling), and for high-pressure systems or potential tube leaks, seal welding is added. Fin welding on economizer tubes is done with High-Frequency Welding, ensuring metallurgical bonding and improved heat transfer efficiency.

Welders must hold valid certifications according to international standards such as EN287. - Insulation and Cladding: After the structural assembly is complete, the boiler body is insulated with high-grade refractory ceramic fiber insulation to minimize energy losses and improve thermal efficiency.

Quality Control and

Testing

- Weld Inspections: All welds are rigorously inspected by authorized inspectors from the Iranian National Standards Organization using non-destructive testing (NDT) methods such as Radiographic Testing (RT), Ultrasonic Testing (UT), Penetrant Testing (PT), and Visual Testing (VT).

- Hydrostatic Testing (Cold Test): Upon completion, boilers are hydrostatically tested with water at 1.5 times the design pressure to ensure strength and safety under high-pressure conditions.

- Auxiliary Equipment Installation: Essential equipment such as burners, feedwater pumps, water level controls, pressure switches, safety valves, discharge valves, feed valves, and electrical/control panels are installed and tested for proper operation.

- Initial Commissioning (Hot Test): For small-capacity boilers, initial commissioning may be carried out at the factory, but for large-capacity units, it is performed on-site by specialized engineers. In most watertube boilers, hot testing occurs after final installation.

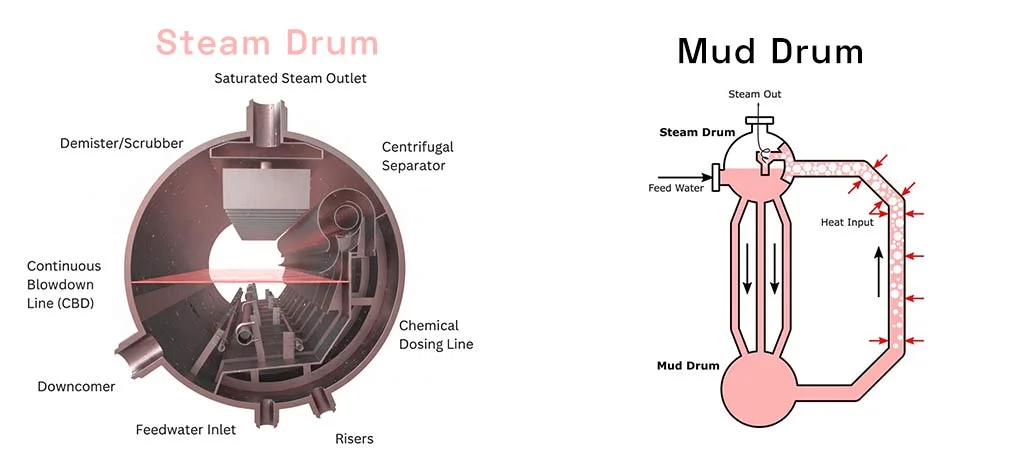

How a Water Tube Boiler Works?

Water-tube boiler: Feedwater, after passing through preheating equipment such as the economizer, enters the boiler drum. From the drum, water flows through downcomer tubes to the heated sections located in the furnace and along the path of hot flue gases. Inside these tubes, water gradually absorbs heat from combustion and transforms into a mixture of water and steam. This mixture, due to its lower density, rises through riser tubes back to the drum. Within the drum, steam separates from the remaining water. The generated steam at the top of the drum is collected, while the leftover water re-enters the circulation cycle. This continuous water and steam circulation forms the basis of stable boiler operation. When dry or superheated steam is required, the steam leaving the drum is directed to the superheater, where its temperature rises and becomes ready for use in turbines or industrial processes. Precise control of pressure, temperature, and water flow ensures fast startup, high safety, and stable performance under varying loads.

Applications of

Water-Tube Boilers

Watertube boilers, due to their unique ability to generate steam at high pressure and temperature along with excellent thermal efficiency, are widely used in a broad range of heavy industries and critical processes.

Power Generation Plants

Watertube boilers are widely used in thermal and combined-cycle power plants. The steam produced drives steam turbines for electricity generation. These boilers are capable of producing superheated steam at temperatures up to 550 °C and extremely high pressures, which are essential for maximizing turbine efficiency and preventing blade erosion due to water droplets

Oil, Gas, and Petrochemical Industries

These industries require high-pressure, high-capacity steam for heating, separation, chemical reactions, and material transfer. Due to their ability to meet these demands and offer improved safety in hazardous environments, water tube boilers are extensively applied in refineries and petrochemical complexes.

Other Industries

Beyond power and petrochemical sectors, water tube boilers are used in industries with significant steam demand, such as textiles, chemicals, sugar mills, paper mills, leather and rubber manufacturing, packaging, and more.

Capacity of Water-Tube

Boilers

The capacity refers to the maximum amount of steam a boiler can generate within a given time (commonly measured in kg/hr or lb/hr). Package water tube boilers typically range from 5 tons/hour up to 180 tons/hour, while utility (hanging) boilers exceed 180 tons/hour. Proper capacity selection depends on consumer requirements and the cumulative steam demand of all downstream equipment.

Operating Pressure of

Water-Tube Boilers

Designed specifically for high-pressure service, watertube convert water into steam within tubes under extreme pressures while minimizing explosion risks due to reduced water volume. Package types typically operate in the 10–80 bar range (up to ~100 bar), while utility boilers can produce steam at pressures as high as 160 bar.

Steam Temperature in

WaterTube Boiler

These boilers can produce both saturated and superheated steam. Package water tube commonly deliver steam at temperatures up to 500 °C, whereas utility boilers achieve superheated steam at temperatures up to 550 °C.

Water Circulation in

Water Tube Boilers

Efficient water circulation is vital, since not all water within tubes is fully converted to steam. The purpose is to recycle un-evaporated water back into the heating cycle, ensuring higher steam production while preventing thermal stresses and tube damage.

- Natural Circulation: Driven by density differences between hot (lighter) and cold (heavier) water, effective at low pressures.

- Forced Circulation: At higher pressures, the density difference decreases, making natural circulation ineffective. In such cases, feedwater pumps force circulation to ensure adequate steam generation and tube protection.

Conclusion

Water-Tube Boiler, with their ability to deliver high-pressure steam, excellent efficiency, and superior safety, play a critical role in heavy industries and modern power plants. Their diverse design options allow customization to meet specific industrial requirements.

Although they involve higher initial investment costs, their operational benefits make them a justifiable and strategic long-term investment. The future of watertube boiler technology lies in further efficiency improvements, emissions reduction, adoption of alternative fuels (such as hydrogen, biomass, and renewable-based fuels), and expanded automation systems—all of which will continue to reinforce their importance in industrial energy supply.

Water Tube Boiler Mountings are essential for the safe and efficient operation of steam boilers. In this article, we cover key Boiler mountings including steam stop valves, safety valves, feed water regulators, pressure gauges, blowdown valves, level indicators, air release valves, and TDS sensors.You will learn how each component helps control water and steam levels, protect the boiler from overpressure or contamination, and ensure smooth operation.

Water Tube Boiler Mountings

Explore the essential mountings that keep water tube boilers safe and efficient: Main Steam Stop Valve, Auxiliary Steam Stop Valve, Boiler Safety Valve, Steam Drum Level Gauge Glass, Air Release Valve, Feed Check and Control Valve, Pressure Gauge Connection, Boiler Blowdown Valve, Scum Blowdown Valve, Sampling Connection, Low-Level Alarm, Soot Blowers, Automatic Feed Water Regulator, Manhole, and TDS Sensor and Probe.Learn more about the role of each mounting in maintaining boiler performance and safety.

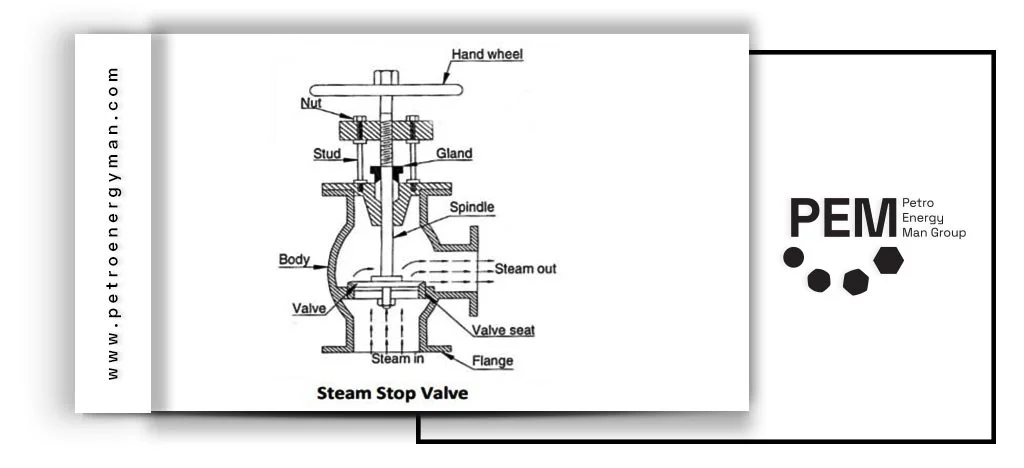

Main Steam Stop Valve

Water Tube Boiler Mountings include the main steam stop valve, which is installed between the main steam line and the distribution header. Its primary function is to allow or stop the flow of steam from the boiler to the steam pipeline, or from the steam line to the consumption process. When open, it directs the generated steam into the main steam line, and when closed, it completely isolates the boiler from the steam system. This valve is typically mounted close to the boiler and must always be operated either fully open or fully closed, never partly open for throttling. In multi-boiler installations, an additional isolating valve must be installed in series with the main valve, and at least one of these valves should be lockable in the closed position. Main steam stop valves are usually globe-type valves with an angular flow path.

Auxiliary Steam Stop Valve

The auxiliary steam stop valve controls the flow of steam to auxiliary steam lines. It is essentially a smaller version of the main steam stop valve and is designed to isolate the boiler from secondary systems. This valve is often manufactured as a check valve to prevent backflow of steam into the boiler in case of malfunction or system failure. It is normally installed directly on the boiler outlet and plays an important role in the safe and reliable operation of auxiliary steam lines.

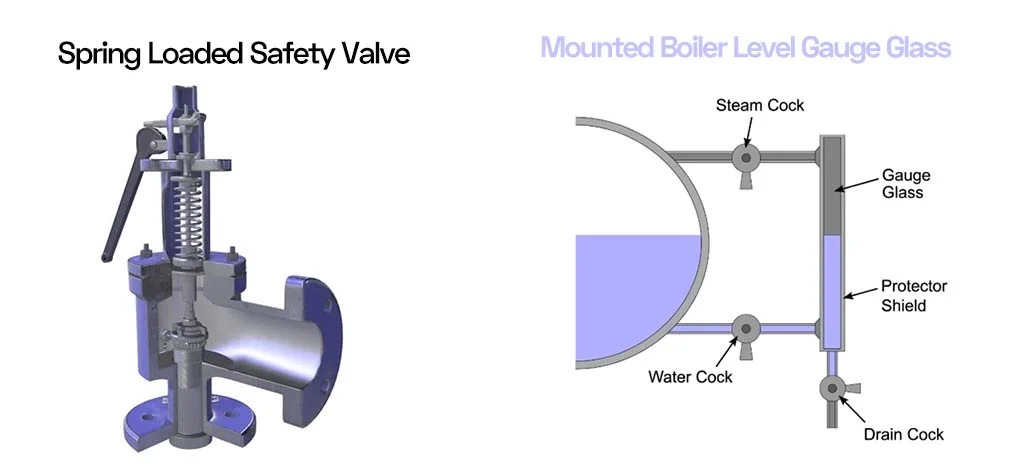

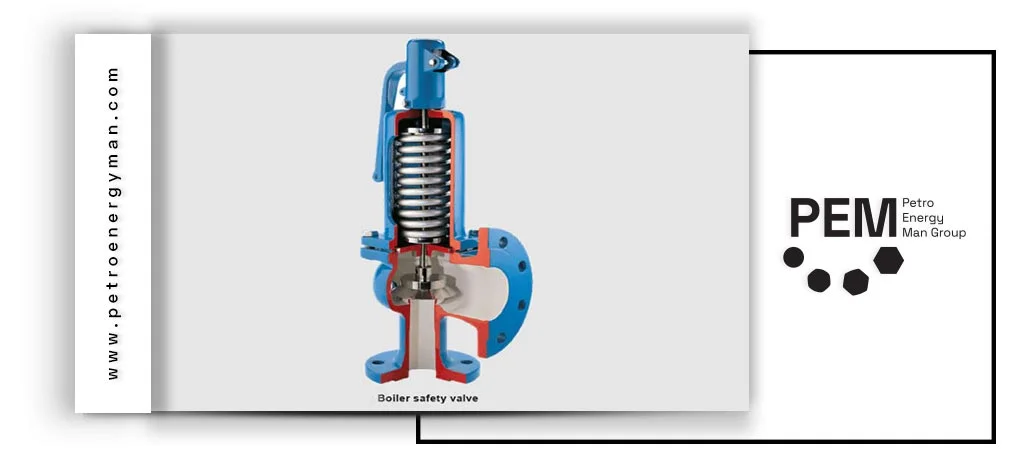

Boiler Safety Valve

Water Tube Boiler Accessories include the boiler safety valve, which is one of the essential components designed to protect the boiler from excessive pressure and prevent potential damage. The primary function of this valve is to automatically release steam whenever the generated steam pressure rises above the allowable limit.

Safety valves are typically installed in pairs: a main valve and a backup valve that is set to open at a slightly higher pressure. This ensures the boiler remains protected even if the main valve fails. The opening pressure of these valves is adjusted and sealed in the presence of an authorized inspector so that no one can tamper with the settings. Safety valves play a vital role in preventing dangerous pressure buildup in steam systems.

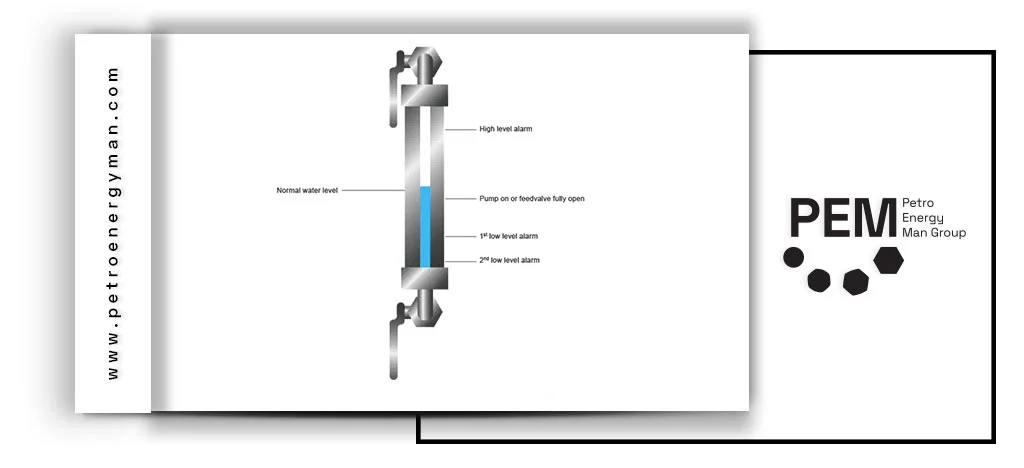

Boiler Steam Drum Level Gauge Glass

The steam drum level gauge glass, also known as the water level indicator, is usually installed in pairs to allow manual monitoring of the water level inside the boiler steam drum. These gauge glasses visually display the water level and protect the boiler from potential damage, as low water levels and excessive temperatures can cause severe failures.

The design and construction of gauge glasses are based on the boiler’s working pressure. They are installed such that their lowest visible point is at least 50 mm above the critical water level to prevent overheating. These glasses must be inspected and tested daily to ensure proper operation and to maintain personnel safety against possible hazards.

Air Release Valve or Boiler Vent

Water Tube Boiler Mountings include the air release valve, which is typically installed on headers and drums to protect the system from damage. This valve prevents sudden vacuum formation in the boiler during pressure drops or rapid steam pressure increases and allows air to escape when filling the steam drum or during steam generation. It can also return excess air into the boiler during venting.

Air release valves are usually installed at the highest points of the system, where air tends to accumulate. They are responsible for removing non-condensable gases such as air, which have no thermal value and can impair the performance of the steam plant by covering heat transfer surfaces or causing corrosion in the condensate system.

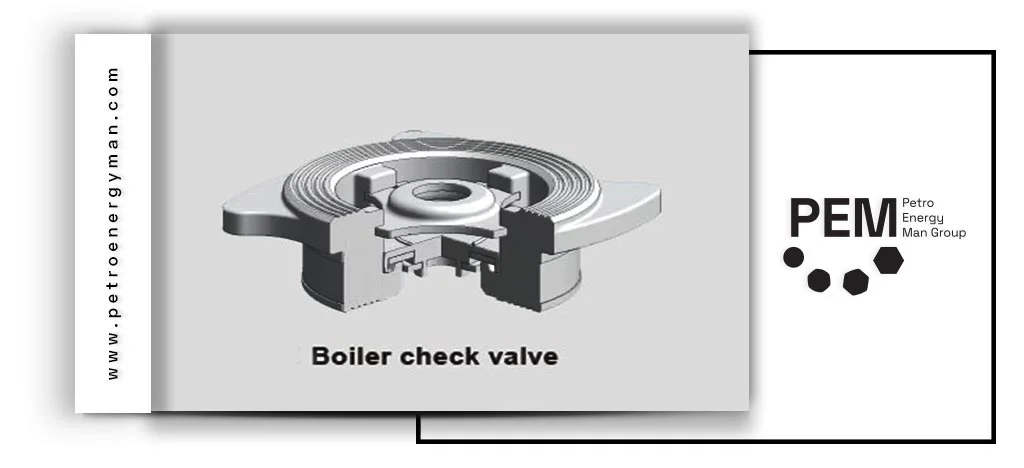

Feed Check and Control Valve

The feed check valve is designed to control the flow of water from the feed pump to the boiler and prevent backflow from the boiler to the pump. This valve ensures one-way flow and is often installed in pairs: a main valve and an auxiliary valve. The main valve is installed in an accessible position to facilitate operation.

These valves often feature a visual indicator showing whether they are open or closed. Using two feed check valves provides double isolation for the feed line, enhancing operational safety and reliability.

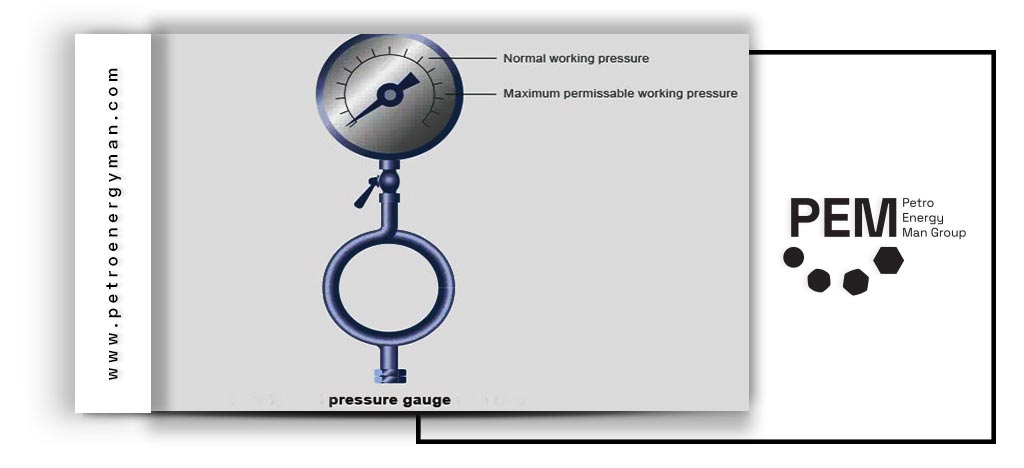

Pressure Gauge Connection

Boiler mountings include a pressure gauge, which every steam generator should be equipped with, typically a simple gauge conforming to EN 12953 standards. Pressure gauges continuously display the pressure inside the boiler and can be connected to the steam space, water column, or steam connection of the boiler. To protect the gauge mechanism from high temperatures, a siphon or equivalent device is often used.

The display should have a minimum diameter of 150 mm and indicate both the normal operating pressure and the maximum allowable working pressure.

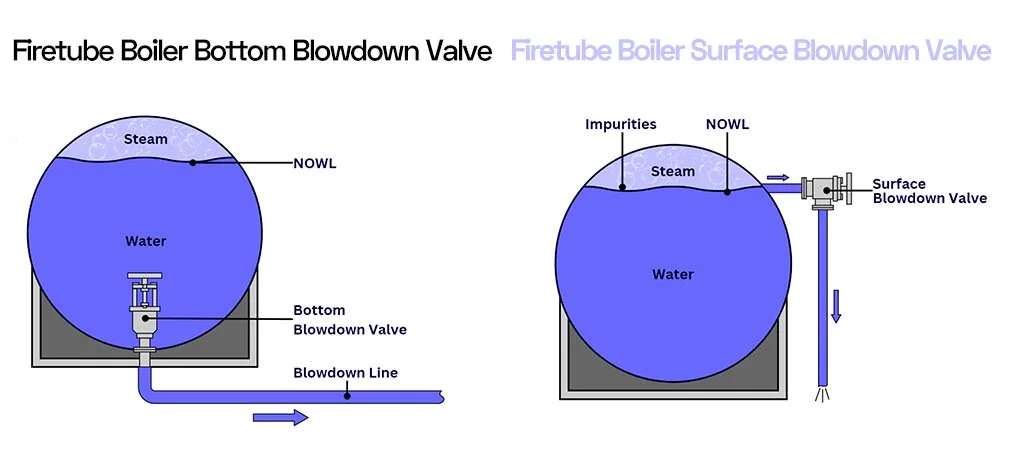

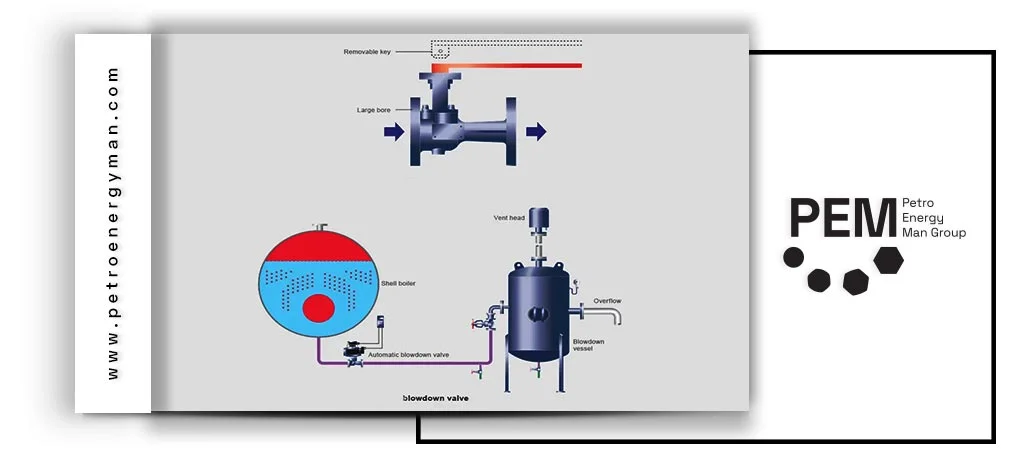

Boiler Blowdown Valve

Boiler mountings also include the boiler blowdown valve, which is used to remove sludge, sediment, and other impurities from the bottom of the water drum. This process, known as blowdown, is essential for maintaining boiler water parameters within acceptable limits, minimizing issues such as scaling, corrosion, and the transport of solid particles.

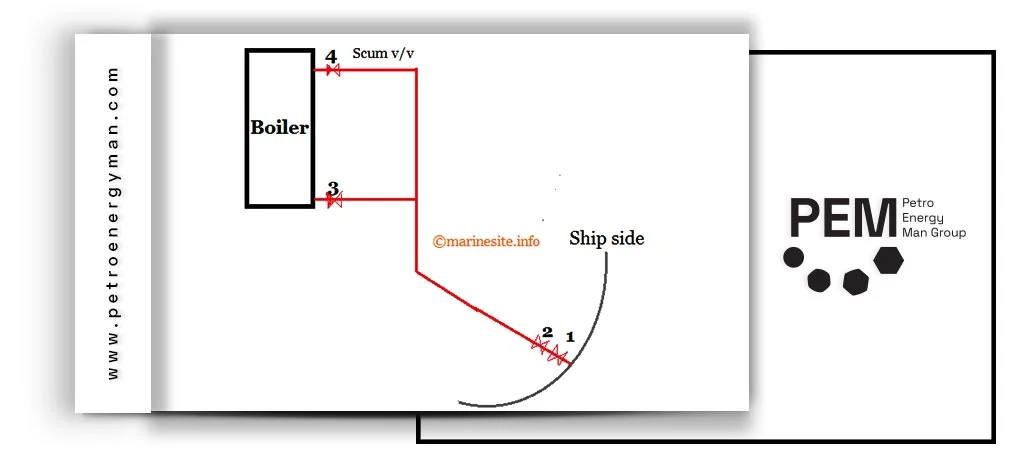

Scum Blowdown Valve

Water Tube Boiler Mountings include the scum blowdown valve, which is designed to remove floating impurities, surface oils, and other scum formed on the water surface. This valve usually features a shallow chamber installed at the water surface, allowing the collection and discharge of floating materials. The scum blowdown valve helps clean the water surface from oily layers or foam caused by agitation or contamination, playing an important role in improving boiler water quality and enhancing system efficiency.

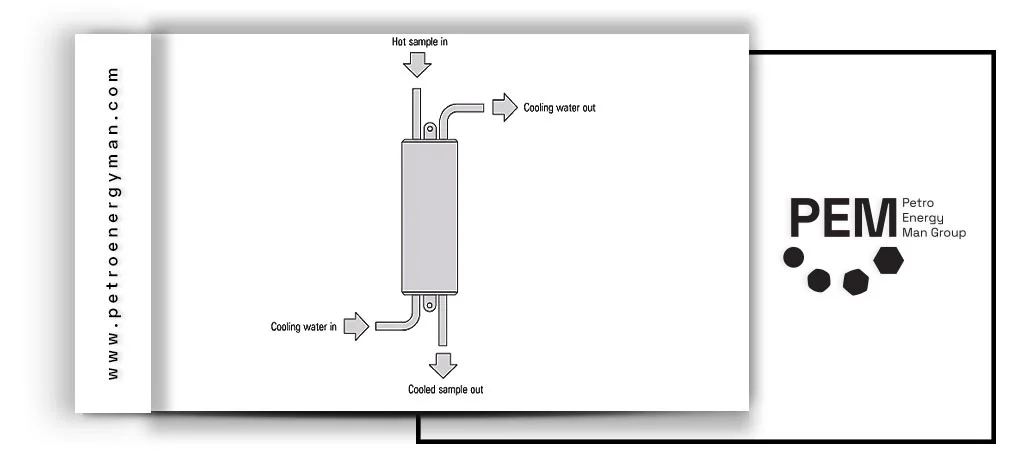

Sampling Connection

The boiler sampling connection typically consists of a control valve and a cooler, allowing the collection of feedwater samples for analysis at any time. The sample cooler is used to increase safety, prevent burns, and maintain the accuracy of test results. These devices prevent sudden evaporation and loss of volatile substances.

To ensure accurate testing and compliance with sampling standards, it is recommended to use stainless steel piping and carefully control the sample’s temperature and flow rate. These practices ensure that the collected samples accurately represent the boiler feedwater quality and provide reliable chemical analysis results.

Low-Level Alarm

Water Tube Boiler Accessories include the low-level alarm, a device that activates an audible warning when the water level in the steam drum drops below a set threshold. This alarm is a critical safety feature for the boiler, preventing continued fuel combustion when the water level is too low. Many systems also include an extremely low-level alarm that can shut down the burner to prevent overheating.

Soot Blowers

Soot blowers are designed to remove soot and combustion residues from boiler tube surfaces, typically using steam or compressed air. Regular cleaning of ash deposits from heat transfer surfaces is essential for maintaining boiler thermal efficiency and controlling flue gas temperatures within the design range.

Soot blowers can be designed as fully retractable, semi-retractable, or wall-mounted on the boiler, allowing cleaning operations without a full boiler shutdown and extending the service life of thermal equipment.

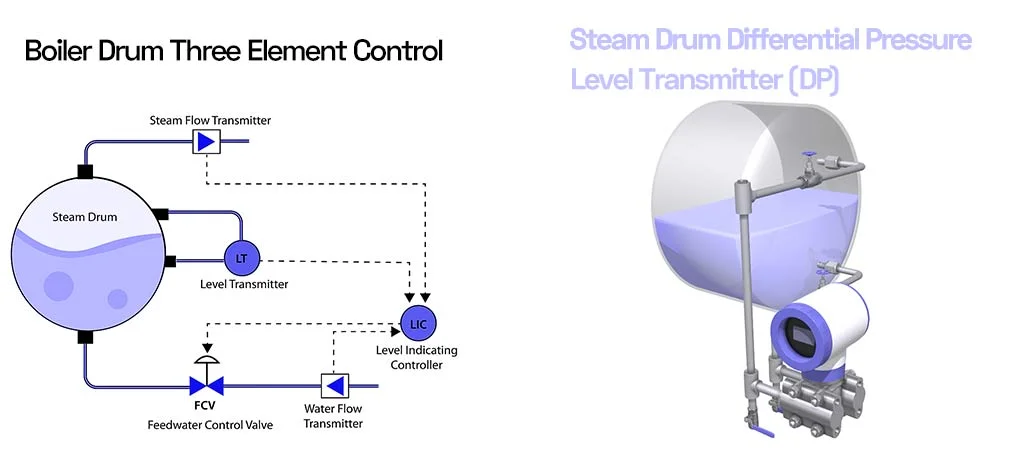

Automatic Feed Water Regulator

Boiler mountings include the automatic feed water regulator, a device that automatically adjusts the incoming water flow to the steam drum to maintain a constant and safe water level, even when the boiler load fluctuates. This device is usually installed on the feed line, before the main feed check valve, and automatically controls the water flow to ensure the desired water level is maintained in the steam drum.

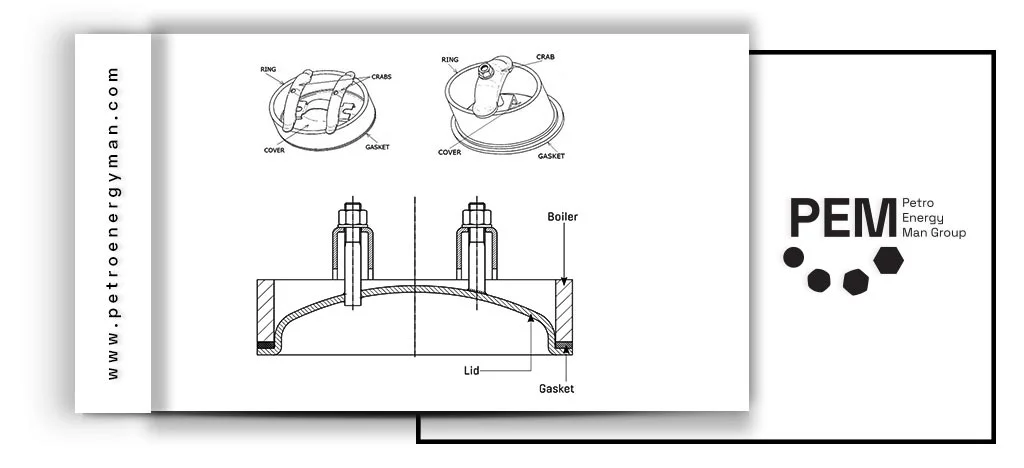

Manhole

Manholes are large openings in the water drum and steam drum that allow personnel to enter for inspection, maintenance, or internal cleaning of the boiler. In water tube boilers, these manholes are provided on all drums to ensure safe access to the interior for maintenance and inspection operations.

Manholes are typically designed in an oval shape, making it easier to install and remove the cover with less stress on the drum. This design ensures safe entry and exit for personnel while preserving the structural integrity of the boiler during opening and closing operations.

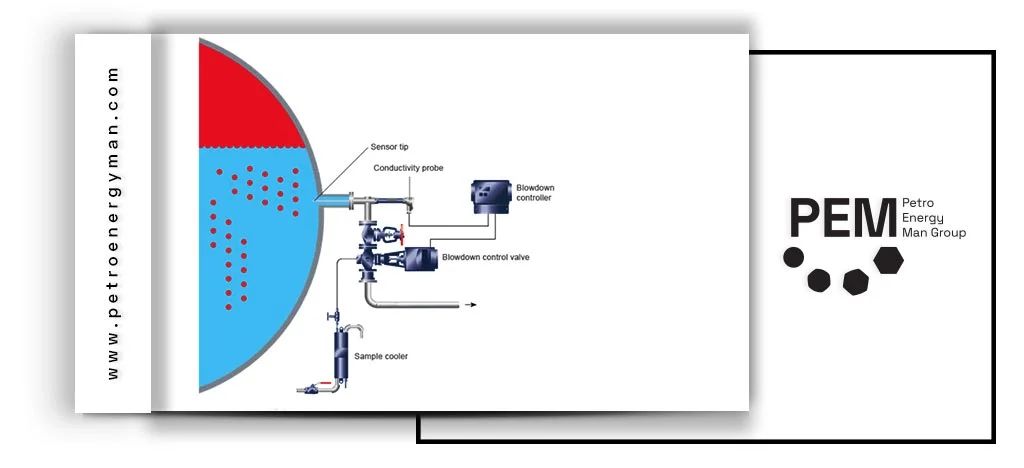

TDS Sensor and Probe

Water Tube Boiler Mountings include TDS (Total Dissolved Solids) sensors and probes, which are used for continuous monitoring of the dissolved solids concentration in boiler water. These devices measure the electrical conductivity of the boiler water to indicate the TDS level, enabling continuous water quality control.

If the TDS level exceeds the permissible limit, audible and visual alarms are activated, and by performing manual blowdown and adding fresh feedwater, the dissolved solids concentration is reduced, optimizing boiler water conditions.

To ensure accuracy and proper performance, regular inspection of TDS probes for physical damage, scaling, and clogging is essential. These inspections guarantee that the sensors consistently provide precise and reliable information about the boiler water quality.

Conclusion

This text provides a comprehensive overview of essential Water Tube Boiler Mountings, each playing a vital role in maintaining the stability and performance of the steam system. These components include main and auxiliary steam stop valves, safety valves, automatic feed water regulators, pressure gauges, steam drum level gauge glasses, blowdown and scum blowdown valves, air release valves, soot blowers, manholes, and TDS sensors.

All of these devices are designed to ensure safety, optimize efficiency, control water and steam levels, and enhance system reliability, playing a key role in the continuous and safe operation of industrial boilers.

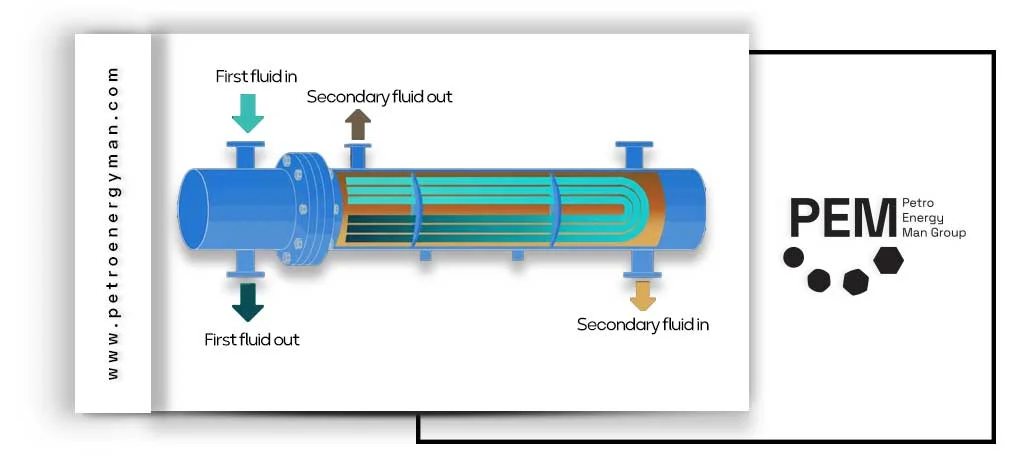

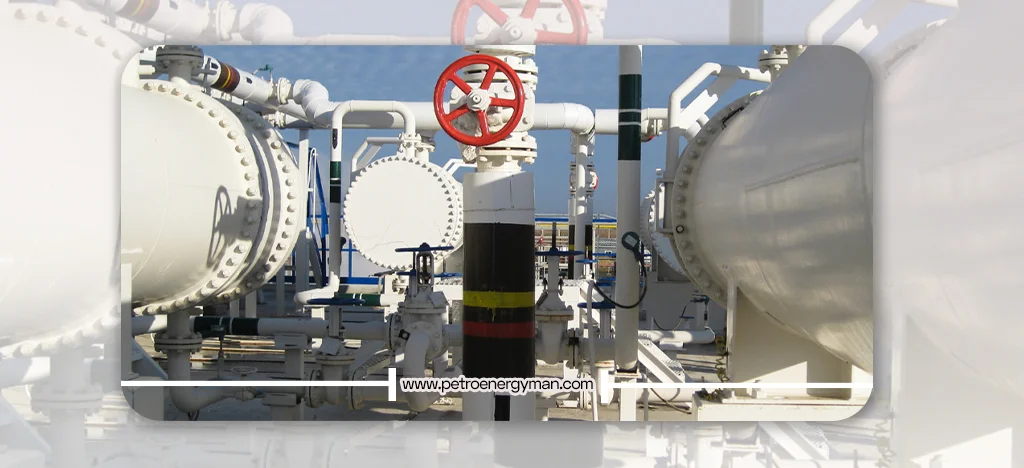

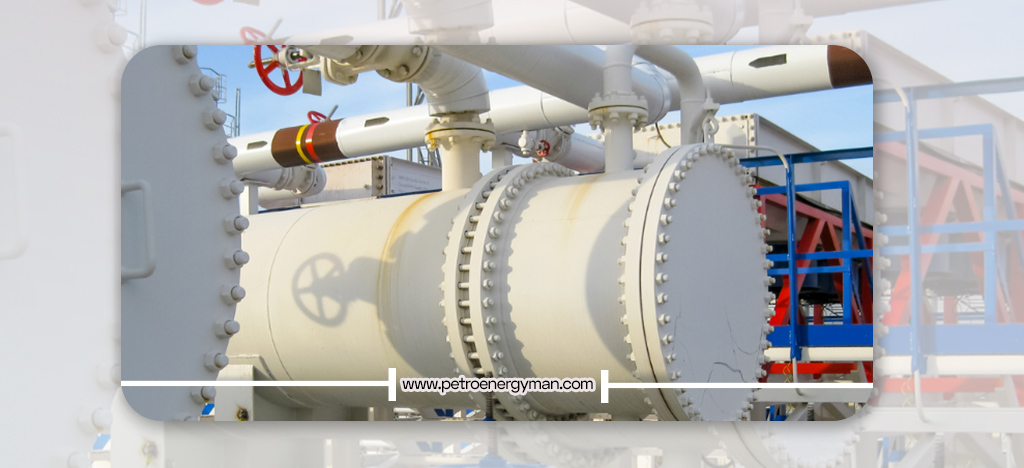

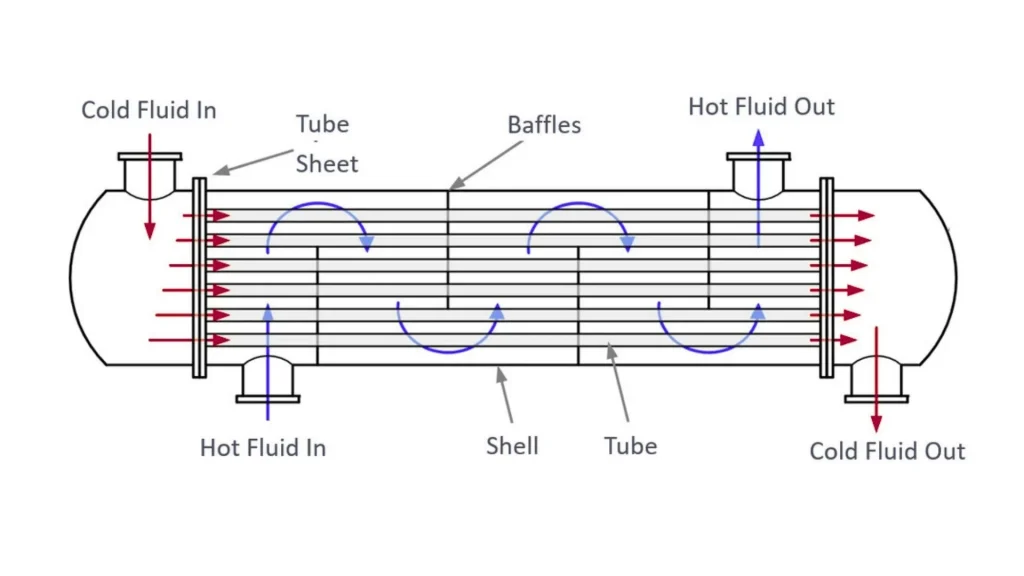

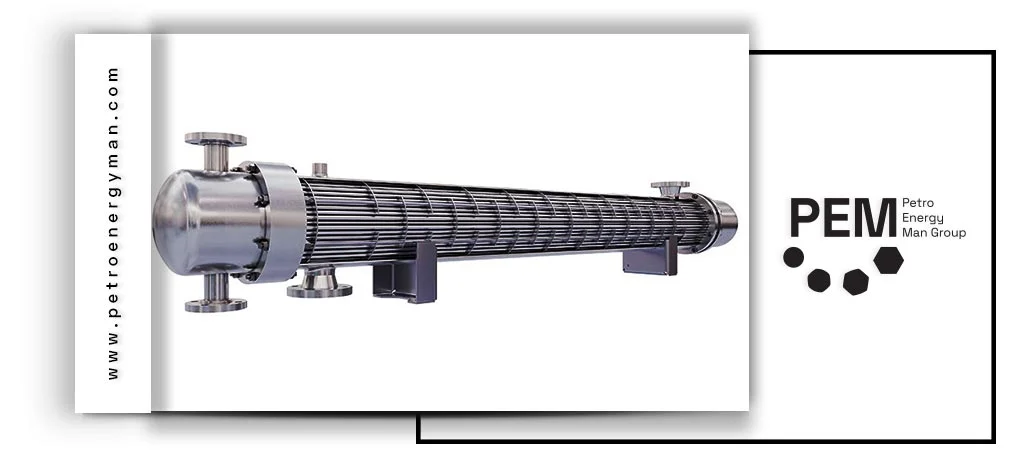

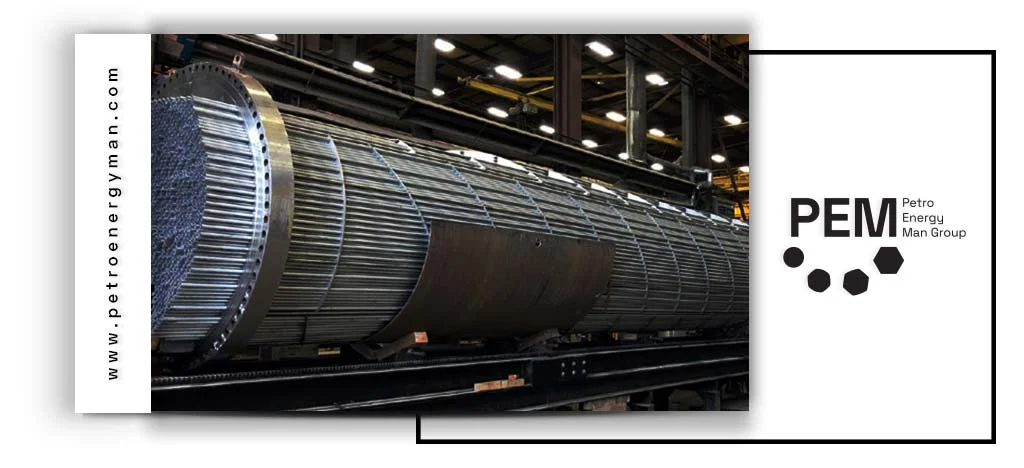

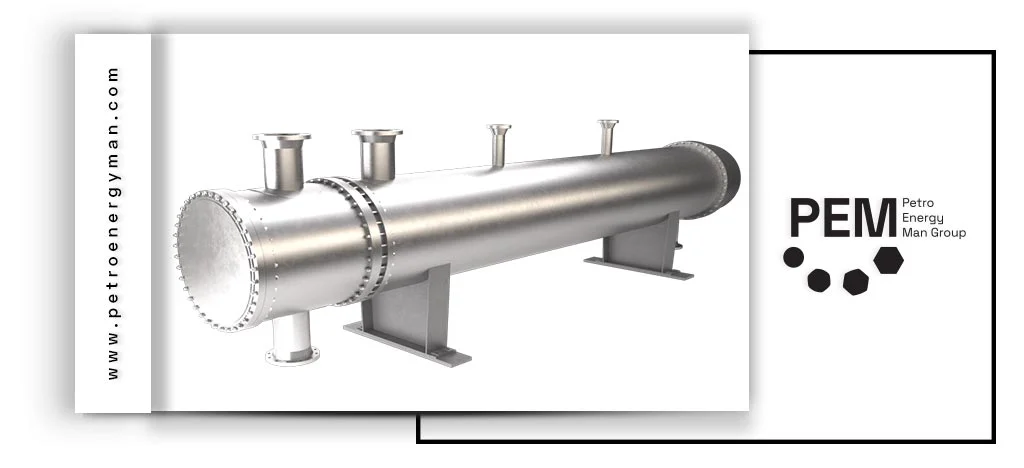

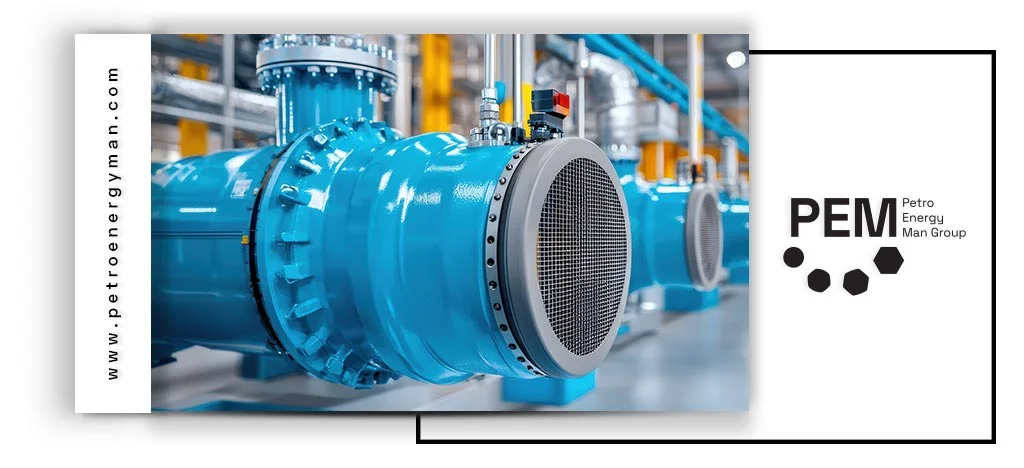

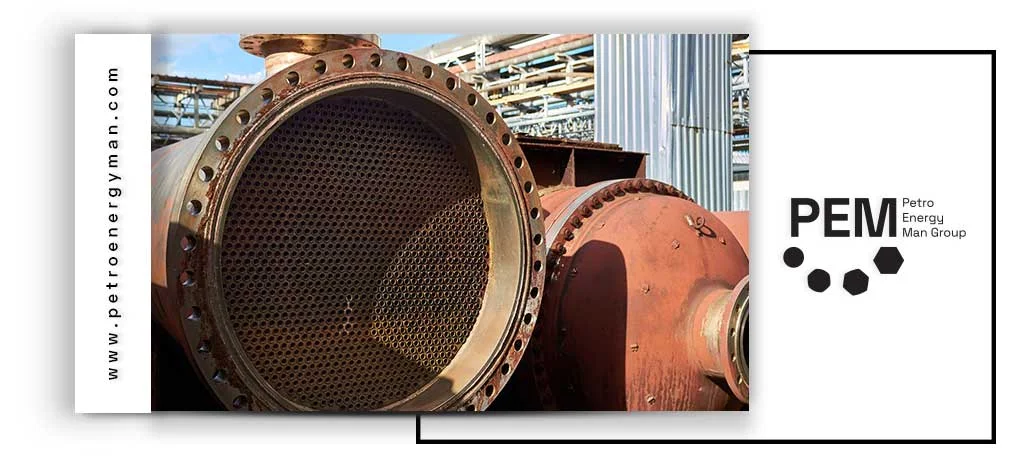

The shell and tube heat exchanger is one of the essential pieces of equipment in many large industries, used for heat transfer between two fluids. This type of exchanger has widespread applications in chemical industries, including crude oil distillation units. This comprehensive text provides an in-depth examination of these types of exchangers, offering complete information about their operation, components, types, applications, and testing methods. Join us to learn about the operation of these vital devices, their key components such as the shell, tubes, and baffles, as well as their diverse designs based on industrial standards and specific needs. This content serves as a comprehensive guide to better understand this complex technology and its broad applications across various industries.

What is a Shell and Tube Heat Exchanger?

A Shell-and-Tube heat exchanger is a device used to transfer heat between two different fluids, usually liquids or gases. This exchanger is one of the most common and widely used types of heat exchangers in various industries. Its name comes from its basic structure, which consists of a large cylindrical vessel called the shell and a number of tubes inside it. This equipment is extensively used in many critical industries such as oil refineries, petrochemical plants, power plants, chemical industries, and other manufacturing processes.

The general heat transfer mechanism in these exchangers is such that two fluids exchange heat with each other without direct mass contact. The fluid requiring heating or cooling flows through the tubes, while the other fluid flows outside the tubes, within the shell. This heat exchange occurs through the metallic tube walls, causing one fluid to heat up and the other to cool down. Ideally, without considering energy loss, the amount of heat lost by the hot fluid equals the amount of heat gained by the cold fluid.

The Shell-and-Tube heat exchanger is one of the most common types of heat exchangers, typically used in oil refineries and large process plants. This type of exchanger consists of a pressure vessel (shell) and a set of closely packed parallel tubes (tube bundle).

Operating Principles of Shell and Tube Heat Exchangers

Tube-and-Shell Heat Exchanger operate based on the concept of flow and thermal contact between two fluids. They transfer heat indirectly between a hot fluid and a cold fluid without the fluids mixing.

How Do Shell and Tube Heat Exchangers Work?

The tube and shell heat exchanger is one of the most widely used industrial pieces of equipment for heat transfer between two immiscible fluids. This exchanger consists of two main parts: the Shell, which is a cylindrical chamber, and the Tube Bundle, which is placed inside this shell. In this system, one fluid flows through the tubes, and the other fluid flows through the space between the tubes and the shell wall. The main objective is to transfer heat from one fluid to the other without them mixing. In other words, heat exchange occurs indirectly.

Fluid Flow Path: One fluid (e.g., the hot fluid) enters the tubes through the inlet nozzle and, after passing through the length of the tubes, exits from the other end. The second fluid (e.g., the cold fluid) enters the shell through another inlet nozzle and flows around the tubes. In this case, the heat from the hot fluid is transferred through the tube walls to the cold fluid without the two fluids mixing.

Flow Arrangement Design: In shell and tube heat exchangers, the movement of fluids can be designed in various configurations:

- Parallel Flow: Both fluids enter from the same side and exit to the same side.

- Counter Flow: Fluids enter from opposite ends and move towards each other. This arrangement usually has higher thermal efficiency.

- Cross Flow: The flow path of one fluid is perpendicular to the flow path of the other fluid.

Design of Shell and Tube Heat Exchangers

The design of Tube-and-Shell Heat Exchanger is one of the specialized processes in mechanical engineering and process industries. The primary goal in this process is to achieve the highest heat transfer rate with the lowest pressure drop and construction/operating costs. This design requires precise selection of geometric structure, suitable raw materials, and the use of advanced software for analyzing and optimizing exchanger performance.

Stages of Shell And Tube Heat Exchanger Design

Tube-and-Shell Heat Exchanger design is a complex process requiring significant knowledge and experience, and various factors must be considered. The general design stages are as follows:

Determining Requirements and Operating Conditions

The first step in heat exchanger design is defining the user’s needs and project specifications. These needs include the type of fluids used, required thermal capacity, fluid temperature difference (inlet/outlet), operating pressure, and cost considerations. The physical and chemical properties of the fluids, such as density, viscosity, and heat capacity, must also be specified at this stage.

Selecting the Exchanger Type

After determining the requirements, the appropriate type of heat exchanger is selected. Heat exchangers come in various types, including shell and tube, plate heat exchangers, double-pipe heat exchangers, and spiral heat exchangers. Shell and tube heat exchangers are one of the most common types. The selection of the exchanger type and baffle configuration is based on operating conditions and project needs.

Calculating Size and Heat Transfer Surface Area

After selecting the exchanger type, the size of the heat exchanger is calculated. This calculation is based on the required heat transfer rate and the overall heat transfer coefficient. The size of the heat exchanger depends on thermal capacity, fluid temperature difference, and heat transfer coefficient. The heat transfer coefficient is influenced by factors such as tube thickness, material properties, and fluid flow conditions.

Material Selection

The material of the shell and tubes must be selected according to operating temperature, pressure, and fluid properties to be resistant to corrosion and erosion. The type of fluids used in the heat exchanger impacts its design.

Mechanical Design

The mechanical design of the heat exchanger is performed after calculating its size. Mechanical design includes determining the exchanger dimensions, tube type, number of tubes, and type of tube sheets and gaskets. This design must comply with standards and safety requirements.

Fluid Flow and Pressure Drop Analysis

Important points regarding the placement of hot and cold fluids and pressure drop must be considered in Tube-and-Shell Heat Exchanger design. The pressure drop in the exchanger must be within the allowable range to ensure system efficiency. Baffles play a crucial role in flow distribution and pressure drop reduction

Using Design Software

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Specialized software plays a significant role in designing and simulating shell and tube heat exchangers. This software helps engineers perform precise and optimized designs. Several powerful software packages exist for Tube-and-Shell Heat Exchanger design, detailed below:

- HTRI Xchanger Suite: One of the most powerful tools for designing and simulating heat exchangers. Developed by Heat Transfer Research, Inc. (HTRI), it provides a wide range of software solutions for heat transfer equipment.

- Capabilities: HTRI Xchanger Suite includes various modules, each used for designing, simulating, and rating specific types of heat exchangers.

- Xist: The main module forTube-and-Shell Heat Exchanger . It allows precise evaluation of thermal performance and pressure drop.

- Xace: Used for designing and rating air coolers and economizers.

- Xphe: Used for plate heat exchangers.

- Xfh: An advanced tool for detailed analysis of fired heaters.

- Xvib: Used for analyzing tube vibrations.

Applications: This software helps operating companies, engineering contractors, exchanger manufacturers, and related industries design, simulate, and optimize heat exchangers with high accuracy.

Measurement of Shell-and-Tube Heat Exchangers

Measuring this type of heat exchanger is a fundamental step in the design and performance evaluation of such systems.

Measurement and Evaluation Methods

The measurement and evaluation of shell-and-tube heat exchangers involve several analytical and experimental methods aimed at optimizing performance and efficiency.

Calculation of Heat Transfer Surface Area

Calculating the tube surface area in a shell-and-tube heat exchanger is essential for designing an efficient system. This area directly affects the heat transfer capacity of the exchanger. The determination of the heat transfer surface area should be based on the required heat duty and the desired capacity of the exchanger.

Thermal and Hydrodynamic Analysis

Extensive experimental and numerical studies have been conducted to investigate the thermal and hydrodynamic performance of shell-and-tube heat exchangers.

- Analytical and Experimental Methods: The heat transfer rate along the tube can be calculated using analytical and experimental techniques. For example, the tube-side heat transfer coefficient in a helical coil has been measured using the Wilson plot method. In addition, numerical studies have been carried out on the freezing and melting behavior of phase change materials in triple-tube heat exchangers using fins and nanoparticles.

- Modeling and Simulation: Thermal modeling of shell-and-tube heat exchangers is performed using the e-NTU method, and optimization is conducted with multi-objective genetic algorithms to enhance efficiency and reduce overall annual costs.

- Effect of Nanofluids: The use of nanofluids such as water–aluminum oxide and multi-walled carbon nanotube–water can significantly improve heat transfer rates. For instance, a water/alumina nanofluid can increase the heat transfer rate by up to 9%, while multi-walled carbon nanotubes in water can enhance the heat transfer coefficient by up to 75%.

Design and Selection Considerations

The selection and sizing of a heat exchanger require an understanding of the types of exchangers, available options, and the application environment. The main criteria for measurement and selection include:

- Exchanger performance: The function of the exchanger (e.g., condensation or boiling).

- Pressure and temperature limitations: Operating pressure (high/low) and the temperature range that may vary during the process.

- Fluid flow capacity: The exchanger’s ability to handle a certain volume of fluid.

- Required materials: Conditions such as sudden temperature changes or corrosive environments may require specific materials.

- Thermal fluid properties: If the fluid is prone to fouling, corrosion-resistant materials may be necessary.

- Space and layout constraints: Physical space limitations and system arrangement can influence the choice of exchanger model.

- Maintenance requirements: Ease of cleaning, repair, and inspection can also be an important factor.

Measurement Tools

Various instruments are used to measure and monitor the performance of heat exchangers, including:

- Temperature sensors: To monitor temperatures at different points in the exchanger.

- Rotameters: For measuring and adjusting the flow rate of hot and cold fluids.

- Control panels and monitoring systems: Including displays and other instrumentation devices for controlling and supervising performance.

- Safety equipment: Appropriate safety tools, such as goggles and gloves, are essential when working with heat exchangers.

These tools, together with thermodynamic calculations and fluid mechanics analysis, contribute to optimal selection and accurate measurement of shell-and-tube heat exchangers.

Price of Shell and Tube Heat Exchangers

The price of shell and tube heat exchangers depends on several factors, including:

- Material of Construction: The type of material used for the shell, tubes, tube sheets, and baffles (e.g., carbon steel, stainless steel, copper, titanium, special alloys) directly affects the price. Materials resistant to corrosion or high temperatures are more expensive.

- Size and Capacity: Larger exchangers with higher heat transfer capacity have higher costs.

- Operating Pressure and Temperature: Design for high pressures or very high temperatures requires thicker materials and more complex manufacturing processes, increasing the price.

- Type and Configuration: Specific types like U-tube exchangers, floating head types, or special baffle designs can impact the final price.

- Standards and Certifications: Compliance with international standards like TEMA (Tubular Exchanger Manufacturers Association) or ASME (American Society of Mechanical Engineers) and the need for specific certifications can add to the cost.

- Ancillary Equipment: The presence of equipment like valves, instrumentation, insulation, and supports also affects the final price.

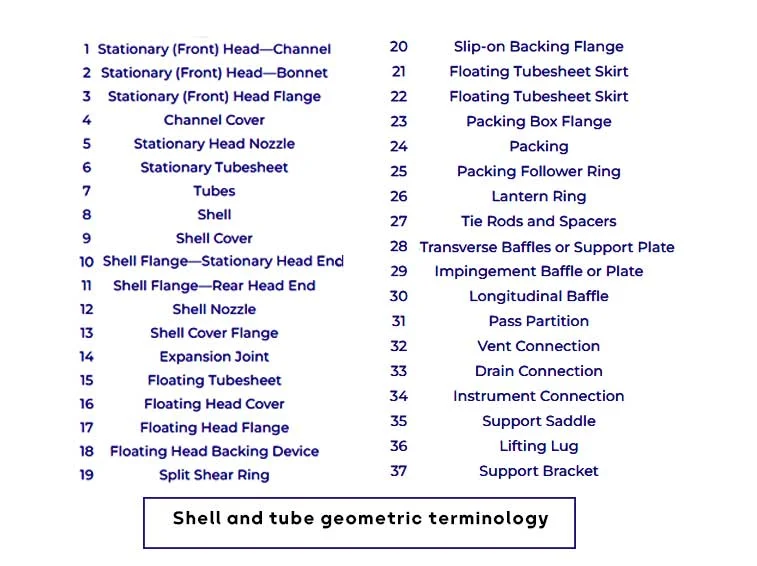

Geometric Terms in Shell and Tube Exchangers

Components of Shell And Tube Heat Exchanger

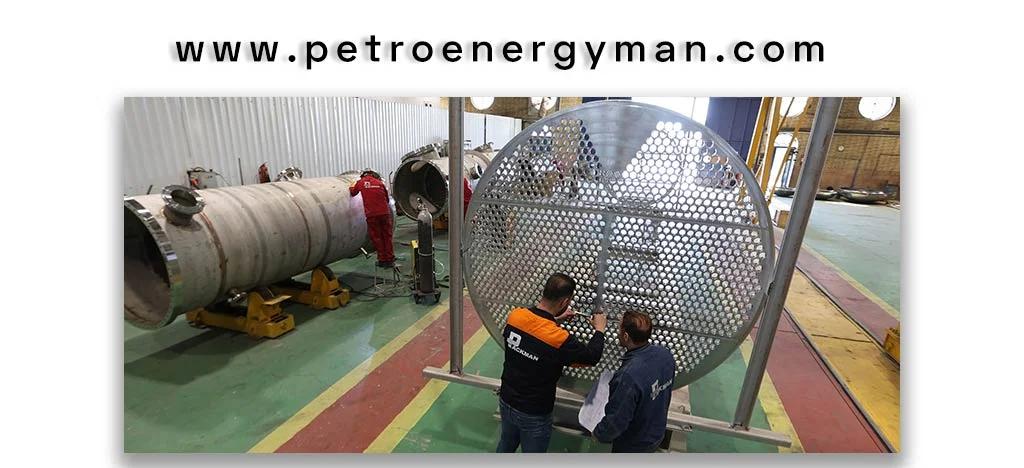

Tube-and-Shell Heat Exchangers consist of numerous components, each playing a vital role in the system’s performance and integrity. Understanding these components and their materials is essential for optimal design, construction, and maintenance.

Shell

This is the large pressure vessel that houses the tube bundle. Its function is to direct the flow of the fluid outside the tubes and ensure efficient heat transfer.

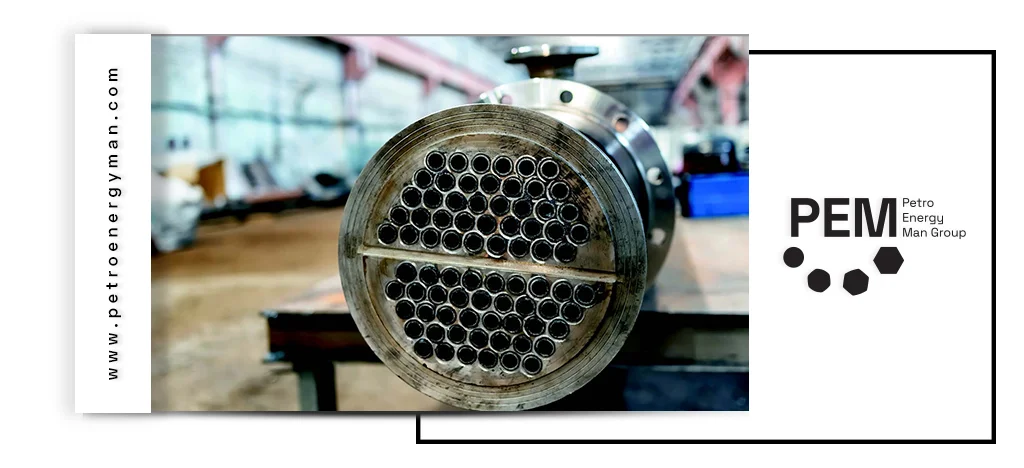

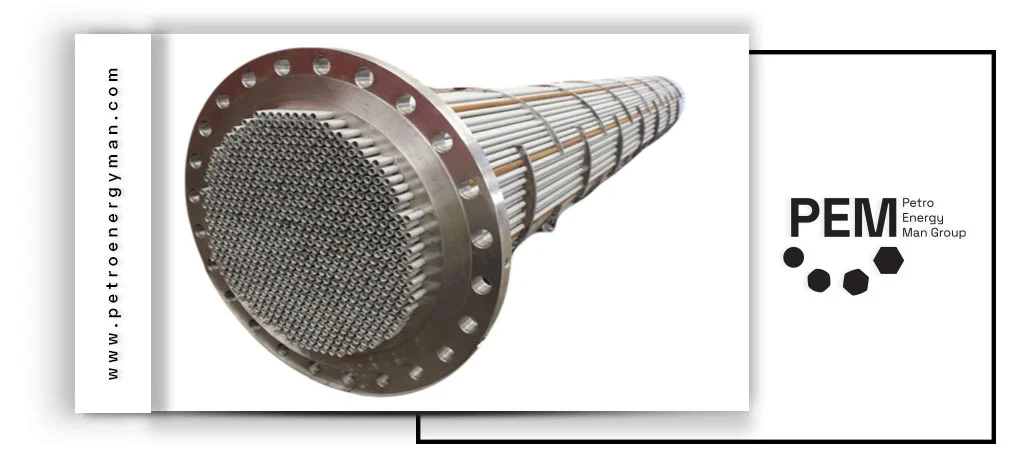

Tubes

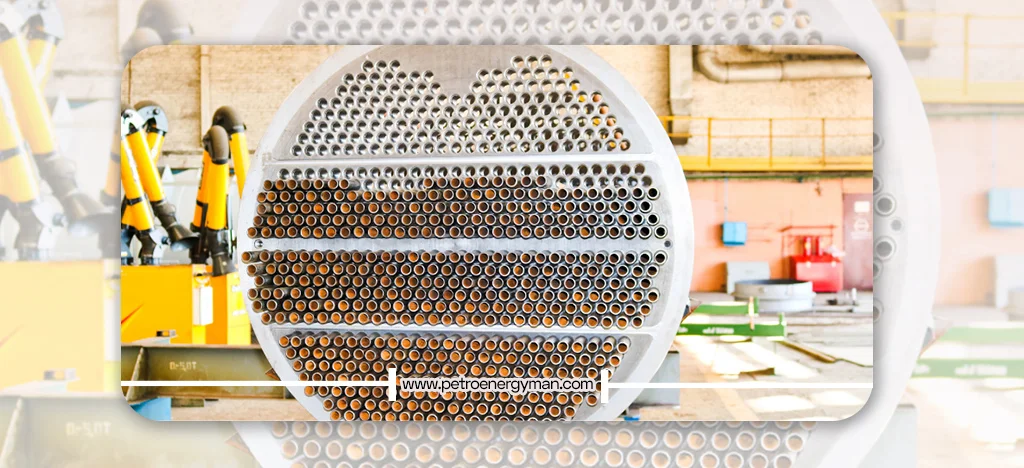

Tubes are the primary heat transfer elements through which the primary fluid flows. They are typically made of high-quality stainless steel or copper, known for excellent thermal conductivity and durability. Seamless tubes are produced via extrusion, while welded tubes are made by rolling a strip into a cylinder and welding the seam; welded tubes are usually more cost-effective. Common tube diameters are 5/8, 3/4, and 1 inch. Tubes with smaller diameters are more difficult to clean mechanically, while larger tubes are used to facilitate cleaning or reduce pressure drop. Tube wall thickness typically ranges between 12 to 16 BWG (0.109 to 0.065 inches). Thinner-walled tubes (18 to 20 BWG) are used when expensive materials like titanium are employed.

Tube Sheets

These are thick metal plates with precisely drilled holes for securing the tubes. Tube sheets are critical for maintaining the structural integrity of the heat exchanger and preventing fluid mixing. They must resist corrosive attack from both fluids and be electrochemically compatible with the tube and tube-side materials. The “tube pitch” is the distance between tube hole centers, typically 1.25 times the outer tube diameter. Triangular pitch is used for higher heat transfer and compactness, while square pitch is used for easier mechanical cleaning. Forged tube sheets are produced using compressive forces, resulting in higher strength and durability compared to casting or machining methods, making them ideal for high-stress applications.

Baffles

Baffles are metal plates strategically placed inside the shell to direct the fluid flow across the tubes. They improve heat transfer efficiency by increasing fluid velocity and ensuring multiple passes over the tubes.

Tie Rods and Tie Rod Nuts

Tie rods hold the baffles in place and maintain their spacing within the shell. Nuts secure these rods, ensuring the stability and alignment of the entire assembly.

Spacer Tubes

These tubes maintain the proper distance between baffles and ensure uniform tube spacing within the bundle. They prevent tube contact, which could cause damage and reduce efficiency.

Body Flanges and ANSI Flanges

These parts connect different sections of the heat exchanger, enabling easy assembly, disassembly, and maintenance. Designed for tight sealing and strong connections.

Studs and Nuts

Used to fasten flanges and ensure a strong seal, preventing leaks.

Applications of Shell and Tube Heat Exchangers in Industries

The high adaptability and reliability of shell and tube heat exchangers make them an integral part of a wide range of industries. Their widespread use across various sectors, from heavy and processing industries to sensitive areas like food and pharmaceuticals, demonstrates their robustness and unparalleled ability to adapt to different fluids, temperatures, and pressures. These features make them a fundamental technology, not just a specific solution, but a vital component in industrial infrastructure.

Oil, Gas, and Petrochemical Industries: These exchangers are used for heating or cooling chemicals, oils, and gases in processes like distillation, condensation, and chemical reactions. In refineries, they are used for crude oil distillation, preheating and cooling fluids, maintaining optimal temperatures in catalytic reactions, condensing vapors, and cooling towers. Due to their durability and high resistance to harsh temperature and pressure conditions, they are highly suitable for the demanding environments of this industry. They are also used in heat recovery processes during oil-water-gas separation.

Power Generation: In power plants, shell and tube heat exchangers serve as condensers, converting steam water into liquid water for return to boilers. They are critical for maintaining the temperature of turbine and generator cooling water systems, preventing overheating, and ensuring uninterrupted power generation. They are also used for feedwater preheating, gearbox oil cooling, and heat recovery from exhaust gases to increase overall efficiency.

Food and Beverage Industries: Used for pasteurizing, sterilizing, and cooling liquids like juices, dairy products, and sauces. Maintaining precise temperatures is vital for product quality and safety. Stainless steel is a common material choice due to its corrosion resistance and ease of cleaning.

Pharmaceutical Industry: Tube-and-Shell Heat Exchangers are used for precise temperature control in processes such as crystallization, distillation, and sterilization of pharmaceutical materials.

Shell and Tube Heat Exchanger Pressure Testing Methods

Pressure testing is critical for confirming the safety and integrity of pressure vessels. The primary goal is to detect any leaks or weaknesses in the coils and connections. Failure to comply with protocols can lead to equipment damage or catastrophic failures.

Hydrostatic Testing

Hydrostatic testing is one

of the most common and safest methods for pressure testing shell and tube heat

exchangers. In this process, the equipment is filled with clean water and

subjected to pressure exceeding the maximum allowable operating pressure to

ensure there are no leaks, structural defects, or mechanical weaknesses. The

applied pressure is typically between 1.3 to 1.5 times the design pressure, but

according to ASME requirements, it may be up to 4 times the design pressure in

some conditions.

This test is performed in several main stages: First, the

exchanger is completely isolated, and all valves are closed. Then, vents are

installed to remove trapped air bubbles, and the system is completely filled

with water. Next, the water pressure is gradually increased to the specified

limit. This pressure is maintained for a specified duration to allow sufficient

time for inspection. During pressure application, the operator visually

inspects all welds, connections, and flanges to ensure there are no leaks or

defects.

After completing the test, the pressure is slowly reduced, and the

water is drained. The exchanger is then thoroughly dried to prevent internal

corrosion. Important considerations for this test include maintaining suitable

water and equipment temperatures. The water temperature should be at least 60°F

(15°C), and the metal temperature should not be below the minimum design

temperature to prevent thermal cracking. Compared to gas methods, hydrostatic

testing is safer because the stored energy in liquids is significantly less

than in gases, thus greatly reducing potential hazards in case of leaks or

failures.

Pneumatic Testing

Pneumatic testing is a common method for assessing the strength and sealing of heat exchangers and other pressure equipment, especially when water cannot be used or is undesirable due to reasons like preventing moisture ingress or difficulty in complete drainage. In this method, compressed gases such as air, nitrogen, or other inert gases are used instead of water. In the pneumatic testing process, gas is introduced into the system in a controlled and gradual manner to increase the pressure uniformly.

The test pressure is usually set at 1.1 times the maximum working pressure. If there is a leak, the sound of escaping gas or visible signs are usually quickly detectable. However, unlike hydrostatic testing, pneumatic testing carries a higher risk because compressed gases store significant energy and can cause serious damage or even life-threatening hazards in case of sudden rupture or leakage. Therefore, strict adherence to safety precautions is essential.

The test must be performed in a controlled environment following stringent safety protocols. To reduce risk, operators often use cameras or remote monitoring equipment to observe the test status without physical proximity. Also, the number of people present on-site should be minimized. Overall, pneumatic testing is an effective and precise solution under specific conditions but requires careful management and completely safe execution to ensure reliable equipment performance without creating hazards.

Precision Leak Testing (Leak Test)

Precision leak testing is one of the most advanced and sensitive methods for assessing the integrity of pressure equipment like heat exchangers. This test is particularly applicable in industries where even the smallest leak can have serious consequences, including pharmaceuticals, nuclear, high vacuum, and other applications requiring complete sealing.

Among various methods, Helium Mass Spectrometry is the most accurate and widely used technique. In this method, helium gas is used as the tracer material because its small atoms can pass through the tiniest cracks and pores. After injecting the gas inside or around the equipment, the spectrometer measures the leak rate with very high precision, in scales of ppm (parts per million) or ppb (parts per billion). This test can detect microscopic leaks that are undetectable by traditional methods and is therefore used as a standard tool in sensitive industries.

Early and precise detection of such leaks can prevent safety, environmental, or operational hazards and reduce costs associated with production stoppages or emergency repairs.

Scanning and Detection Tools

Scanning and detection tools play an important role in monitoring the internal condition of heat exchangers and other pressure equipment. These tools are used to identify damage such as corrosion, cracks, erosion, pitting, and internal cavities and serve as a vital complement to pressure tests, enabling non-destructive and precise evaluation.

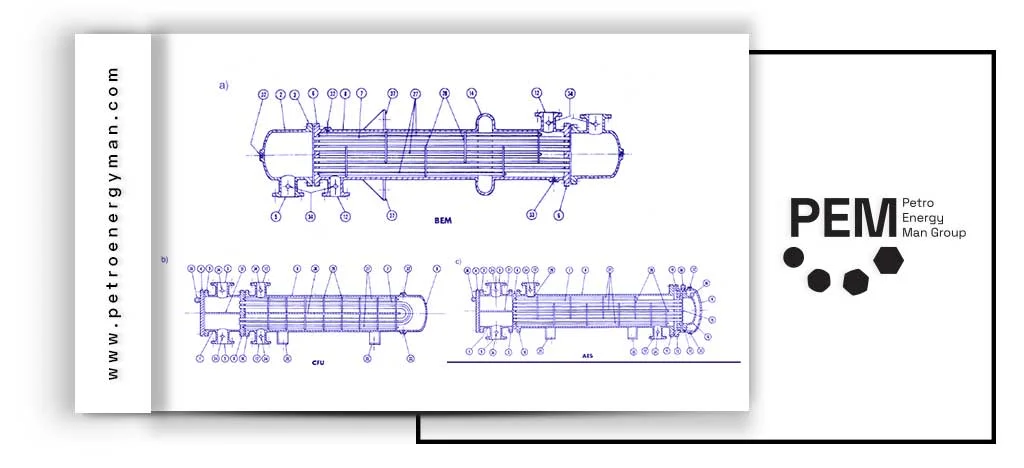

Types of Shell and Tube Heat Exchangers

Tube-and-Shell Heat Exchanger are classified based on various criteria such as design standard, fluid flow mechanism, and material of construction, each with its own advantages and specific applications.

Based on TEMA Standard

According to the TEMA (Tubular Exchanger Manufacturers Association) standard, exchangers are classified based on front/rear head series configuration and shell type. This standard includes different classes, each with specific applications:

- Class B: Tube-and-Shell Heat Exchanger used in chemical processes.

- Class C: Exchangers for general service in various industries.

- Class R: Tube-and-Shell Heat Exchanger designed and used for petrochemical industries and large-scale processes.

Based on Fluid Flow Mechanism

- Shell and tube heat exchangers are also divided into different categories based on how fluids flow within the equipment:

- Parallel Flow: In this type, both fluids move in the same direction, causing the temperature difference between them to gradually decrease along the exchanger.

- Counter Flow: In this case, fluids flow in opposite directions, increasing heat transfer efficiency, commonly used in many applications.

- Cross Flow: In this type, fluids flow perpendicular to each other, typically used in exchangers with specific designs.

- Combined Flow: This involves a combination of the above mechanisms, employed to improve heat transfer and adapt to specific design conditions.

Based on Material of Construction

The selection of the material for shell and tube heat exchangers is based on fluid type, temperature, pressure, and corrosion resistance. This diversity in materials allows exchangers to perform well in very challenging environments and various operating conditions.

Copper: Known for its very high thermal conductivity, commonly used in general applications and situations requiring rapid heat transfer.

Titanium: Due to excellent corrosion resistance, especially in environments containing chlorides and acids, suitable for specific and expensive applications.

Stainless Steel: This material offers good corrosion resistance, and its ease of cleaning makes it a popular choice in food and pharmaceutical industries.

Nickel Alloys: These alloys are used for highly corrosive environments and extreme temperature conditions due to exceptional corrosion resistance and high strength at elevated temperatures.

Carbon Steel: This type of steel is widely used in various industries due to its cost-effectiveness, acceptable corrosion resistance, and suitable thermal conductivity.

Special Materials: Such as graphite, ceramic, composite, and plastic, typically used in special applications requiring specific chemical or thermal resistance.

Based on Operating Pressure and Overall Structure

Exchangers can be designed to withstand different operating

pressures and are categorized by overall structure into the following types: