Brazed plate heat exchangers are compact devices designed for heat transfer between two fluids without direct contact, and they have extensive applications across various industries. This text examines their technical structure, performance advantages, materials used, and main application areas. It also details the role of BPHEs in HVAC systems, cooling, energy and utility services, industrial machinery, and refrigeration, including chillers, heat pumps, waste heat recovery, oil cooling, and refrigerated transport systems.

Brazed Plate Heat Exchangers: Technical Overview

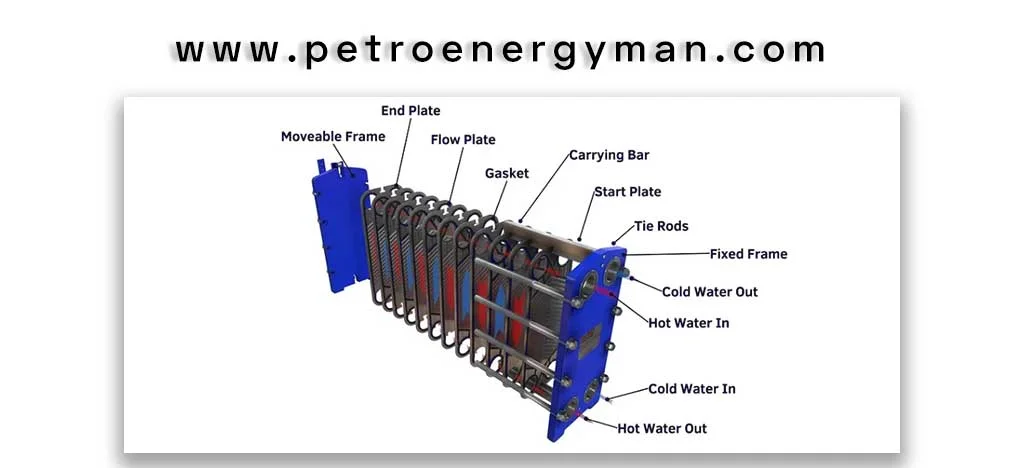

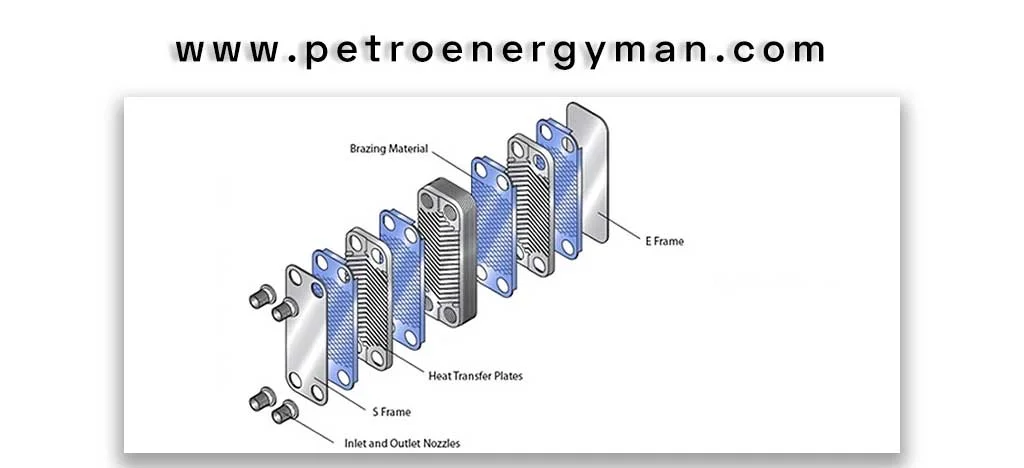

Brazed plate heat exchangers are compact devices designed for efficient heat transfer between two fluids without direct contact. These exchangers are constructed from corrugated stainless steel plates, typically AISI 316, which are brazed at contact points using filler metals such as copper or nickel. The result is a fully sealed unit that can withstand high pressures and temperatures without the need for gaskets.

The manufacturing process involves stacking the plates with the filler metal and heating them in a vacuum furnace at around 450°C. This melts the filler, creating strong and durable joints. The design forms two independent fluid circuits, ensuring effective heat transfer. The corrugated pattern of the plates not only increases the heat transfer surface but also directs fluid flow to maximize contact with the plate surfaces, improving thermal efficiency.

The angle of the plate corrugations plays a key role in determining heat transfer rates and pressure drop. This corrugated design optimizes fluid flow, enhances mechanical strength, and allows the use of thinner plates, resulting in more compact exchangers.As a result, BPHEs offer high thermal performance and are ideal for industrial heating systems, refrigeration, and HVAC applications.

Technical Advantages of Brazed Heat Exchangers

Brazed plate heat exchangers, due to their compact design and high thermal efficiency, are considered one of the most efficient types of industrial heat exchanger. By combining operational flexibility with the use of durable materials, these units represent an optimal choice for production processes that face space limitations while requiring maximum heat transfer performance as an operational priority. Ease of maintenance and effective space optimization have given these systems a prominent position in large-scale industrial projects. In the following sections, each of these advantages will be examined in detail from a technical perspective.

Compactness and Space-Saving

Thanks to their engineered, compact design, brazed plate heat exchangers are an excellent choice for applications where space is limited. Their small size and lightweight construction provide significant flexibility in system design and simplify installation. Technical studies show that these exchangers can reduce weight and volume by up to 90% compared to shell-and-tube heat exchangers with similar performance capacity. This optimized footprint not only conserves valuable equipment space but also significantly lowers transportation, handling, and project implementation costs.

Operational Flexibility

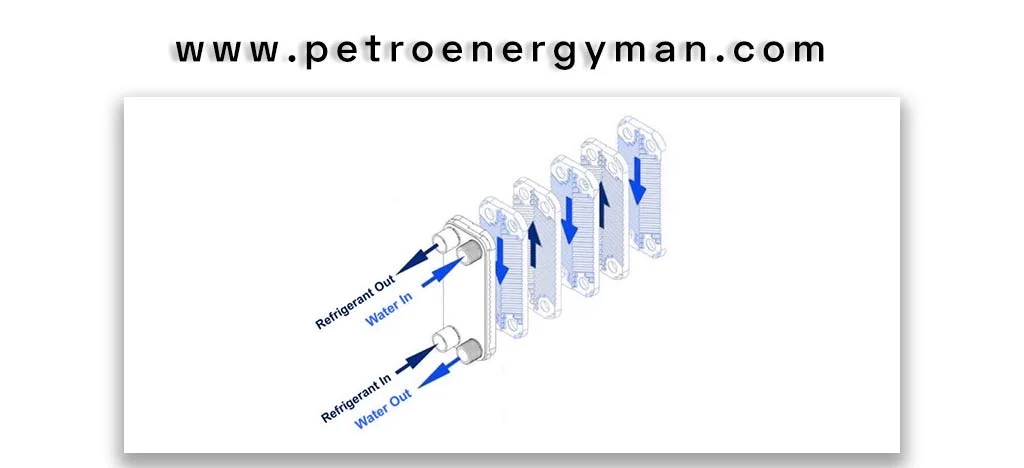

Brazed heat exchangers offer exceptional operational flexibility, allowing them to be designed and configured to meet the specific needs of each application. The ability to select different types of connections and adjust the plate pattern enables engineers to tailor the exchanger precisely to operational conditions and required capacity. Additionally, choosing different flow arrangements—such as co-current or counter-current flow—optimizes heat transfer and enhances overall efficiency.

High Thermal Efficiency

These exchangers deliver significantly higher thermal performance compared to shell-and-tube heat exchangers, while occupying up to 75% less space and footprint. This efficiency is achieved through a large heat transfer surface, induced turbulence, and the possibility of counter-current flow design. The compact design allows for a high heat transfer area in a limited space and supports operation under high fluid pressures. The improved thermal efficiency of BPHEs directly reduces energy consumption and enhances heat recovery in industrial processes.

Durable and Optimized Materials

Brazed plate materials ensure the long-term durability and performance of these heat exchangers. The channel plates are typically made from AISI 316 stainless steel, providing excellent corrosion resistance, while pure copper or nickel alloys are used for brazing to create strong and reliable joints.

In specialized applications or environments with aggressive fluids, using all-stainless steel or high-molybdenum alloys such as SMO 254 offers superior corrosion resistance and maintains surface cleanliness. These materials make BPHEs compatible with a wide range of fluids, including mineral and synthetic oils, organic solvents, water, glycol/water mixtures, and various refrigerants.

Maintenance and Serviceability

One of the main advantages of brazed plate heat exchangers is their simple maintenance. The robust, gasket-free structure minimizes the risk of leaks and reduces the need for frequent servicing. The natural turbulence of fluid inside the exchanger helps keep the plates clean, eliminating the need for constant cleaning in many applications. In systems with a high risk of fouling, cleaning-in-place (CIP) methods can be applied to maintain efficiency and extend the exchanger’s service life.

Overall, the combination of compact design, high thermal efficiency, operational flexibility, and durable materials makes brazed plate heat exchangers a highly reliable option for industrial applications. In this context, collaboration with experienced and specialized heat exchanger manufacturers plays a key role in ensuring system performance, as the precise compatibility of the equipment with the type of fluid, operating pressure, and process requirements can only be achieved through such expertise, guaranteeing optimal long-term performance.

Applications of Brazed Plate Heat Exchangers

Brazed plate heat exchangers have key applications across HVAC, energy, and utility systems.

HVAC & Air Conditioning

In air conditioning systems, these units play a central role in temperature management.

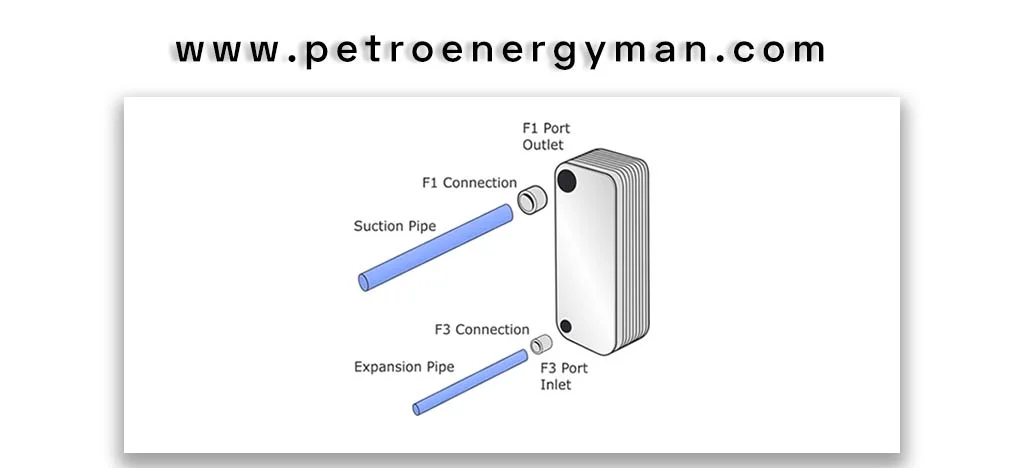

- Industrial and Commercial Chillers: Heat exchanger brazed plate units in industrial and commercial chillers function both as evaporators—absorbing heat from water or process fluids—and as condensers—transferring heat to the environment or cooling towers. Their compact size minimizes chiller installation space, which is especially important in space-constrained industrial environments. High efficiency reduces energy consumption to achieve the desired cooling capacity, lowering operational costs and simplifying compliance with strict energy standards. Optimized channel design and high-pressure tolerance also allow engineers to use low-global-warming-potential (Low-GWP) refrigerants effectively.

- Refrigerated Air Dryers: Brazed plate heat exchangers cool compressed air and condense its moisture. Accurate heat transfer is critical to prevent freezing and maintain low dew points, making them an ideal solution for these systems.

Energy & Utilities

- Heat Pumps: Brazed heat exchanger units in air-to-water or ground-to-water heat pumps transfer heat between a source (ambient air or ground fluid) and building heating systems or domestic hot water. Their ability to achieve low approach temperatures and high efficiency improves the heat pump’s coefficient of performance (COP), resulting in significant energy savings.

- Waste Heat Recovery: Brazed plate heat exchangers are used in waste heat recovery systems, including Organic Rankine Cycles (ORC), to convert excess process heat into useful energy such as electricity or heating. Optimized design and high thermal efficiency allow maximum energy extraction even from low-temperature streams, boosting overall system performance.

- Solar Water Heaters and Boiler Systems: They serve as fluid separators and heat transfer units to domestic or boiler feed water, enhancing system safety, efficiency, and overall equipment performance.

Machinery Equipment

- Hydraulic and Lubrication Oil Cooling: In equipment such as large gearboxes, wind turbines, and plastic injection molding machines, hydraulic and lubrication oils heat up during operation. These heat exchangers cool the oils, preventing oil degradation, reducing component wear, and extending equipment lifespan.

- Laser Welding Machines: Precise and stable cooling of laser sources and sensitive optical components ensures consistent laser beam quality and protects expensive parts from damage.

Refrigeration

- Industrial and Commercial Refrigeration Units: Brazed heat exchanger units in air-to-water or ground-to-water heat pumps transfer heat between a source (ambient air or ground fluid) and building heating systems or domestic hot water. Their ability to achieve low approach temperatures and high efficiency improves the heat pump’s coefficient of performance (COP), resulting in significant energy savings.

- Refrigerated Transport: Limited space and the need to maintain consistent temperatures in trucks and refrigerated containers make these exchangers an ideal choice for cooling systems. Their robust design and high resistance to vibration and shocks ensure stable and reliable operation.

Conclusion

Brazed plate heat exchangers are highly efficient and compact devices used in HVAC systems, energy applications, machinery, and refrigeration. They enable effective heat transfer, reduce energy consumption, and offer easy maintenance. By improving system efficiency and extending equipment lifespan, these exchangers play a key role in enhancing performance and operational savings across various industries.

No comment